Hilscher - Your Partner in Industrial Communication

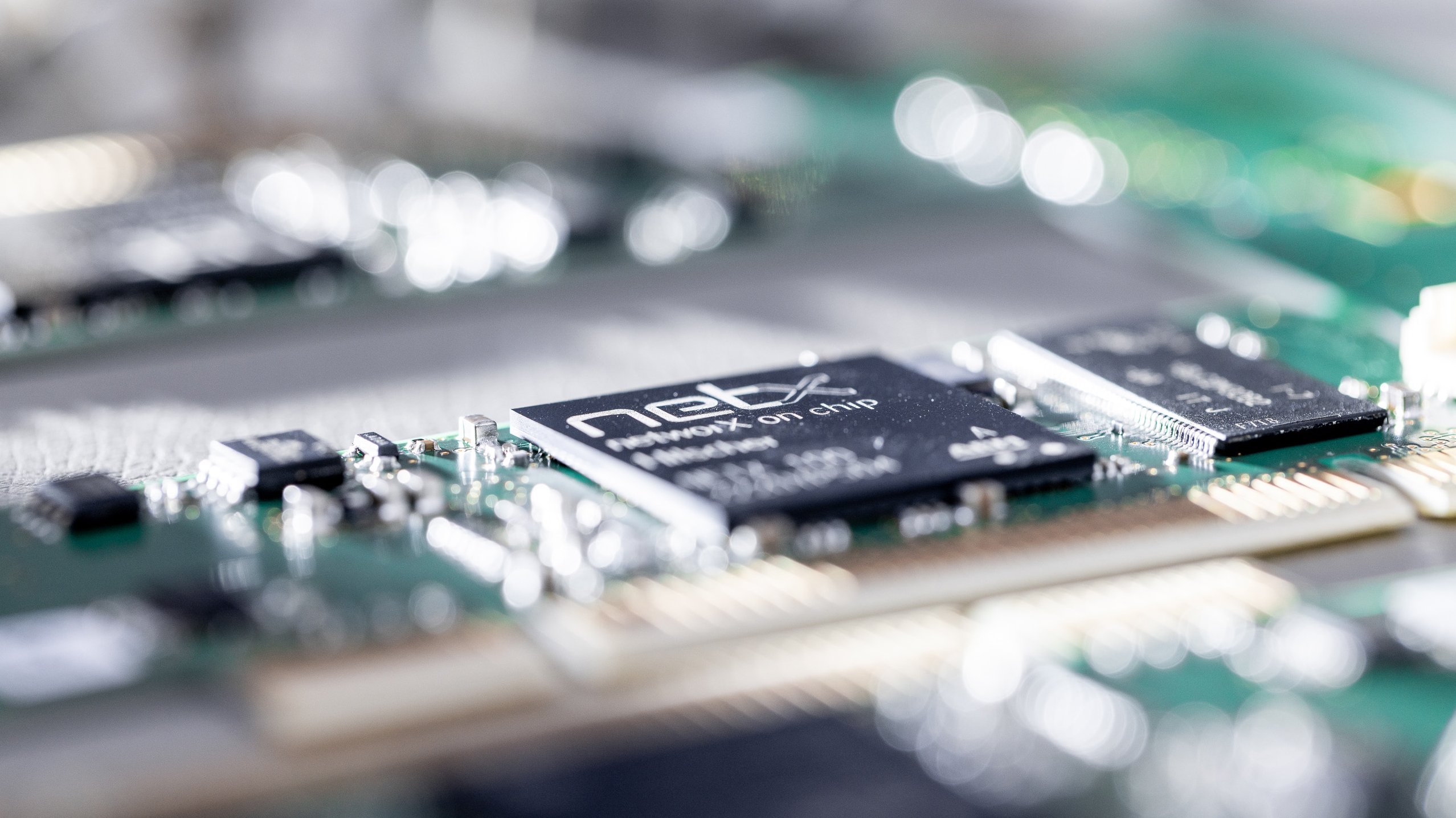

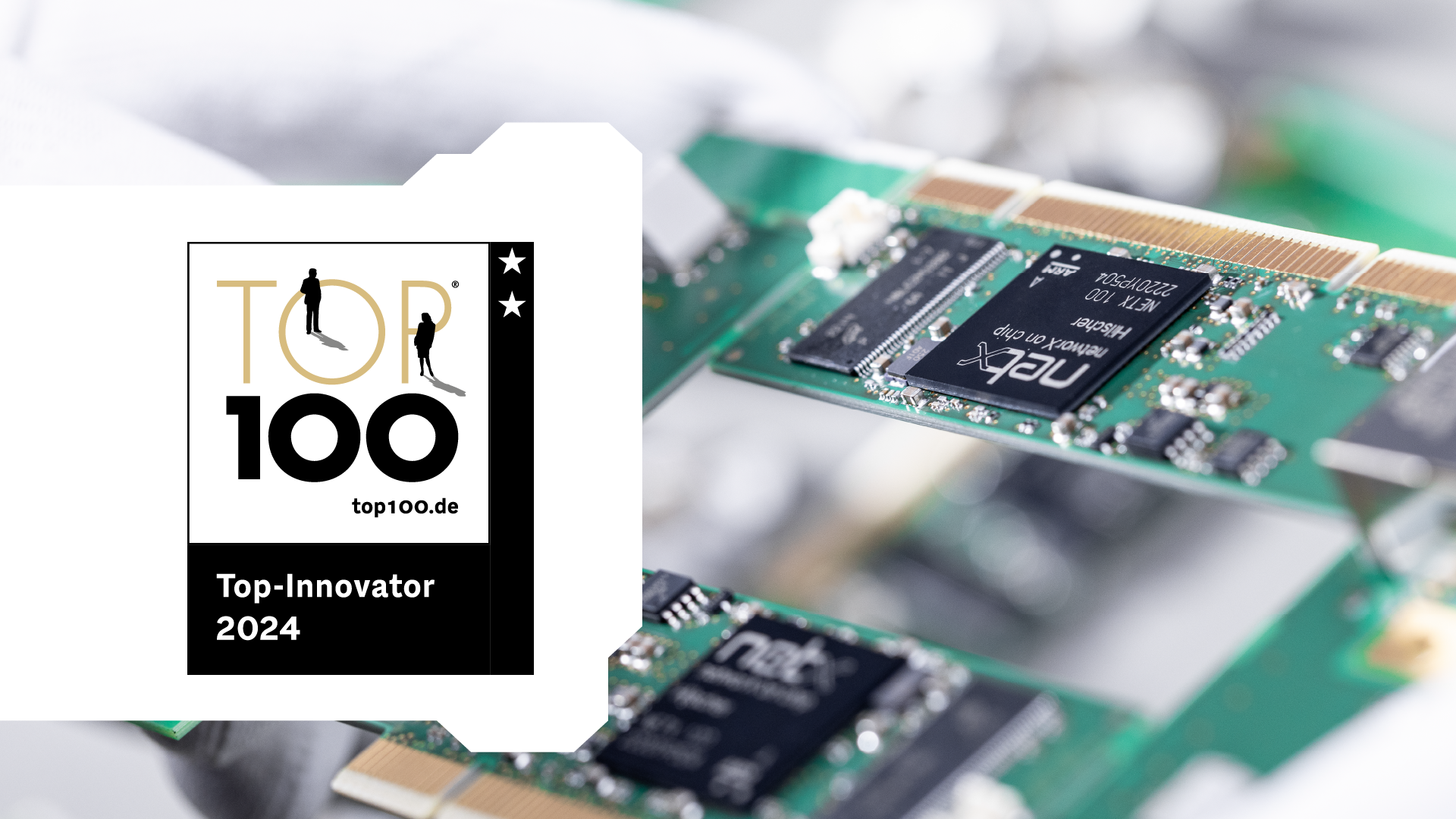

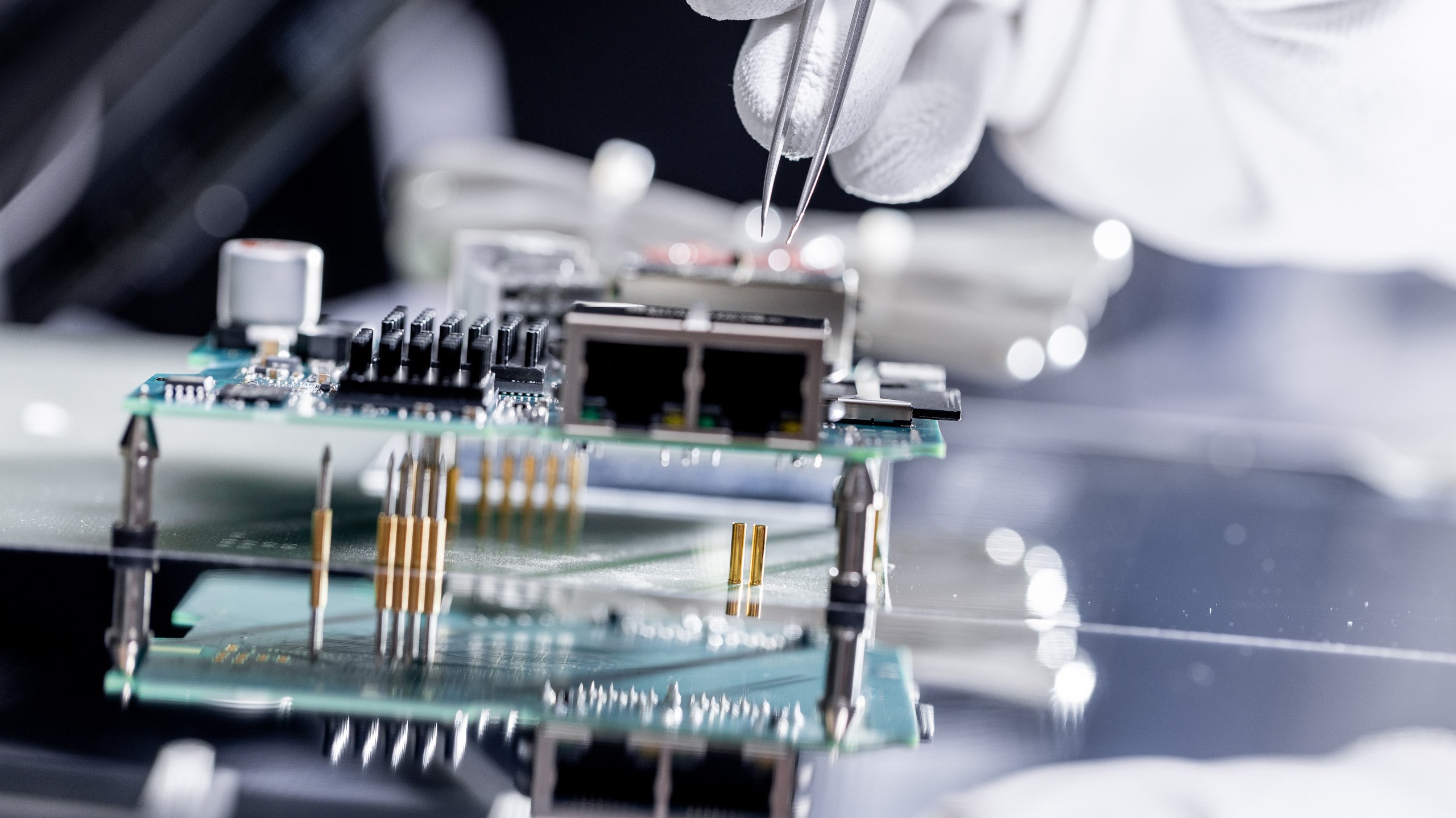

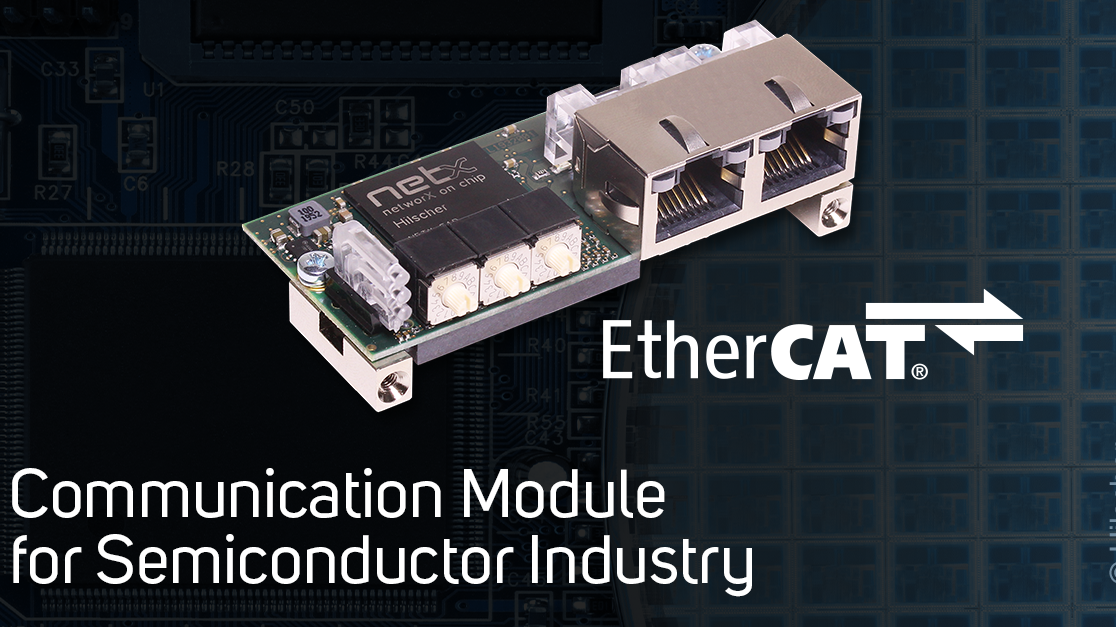

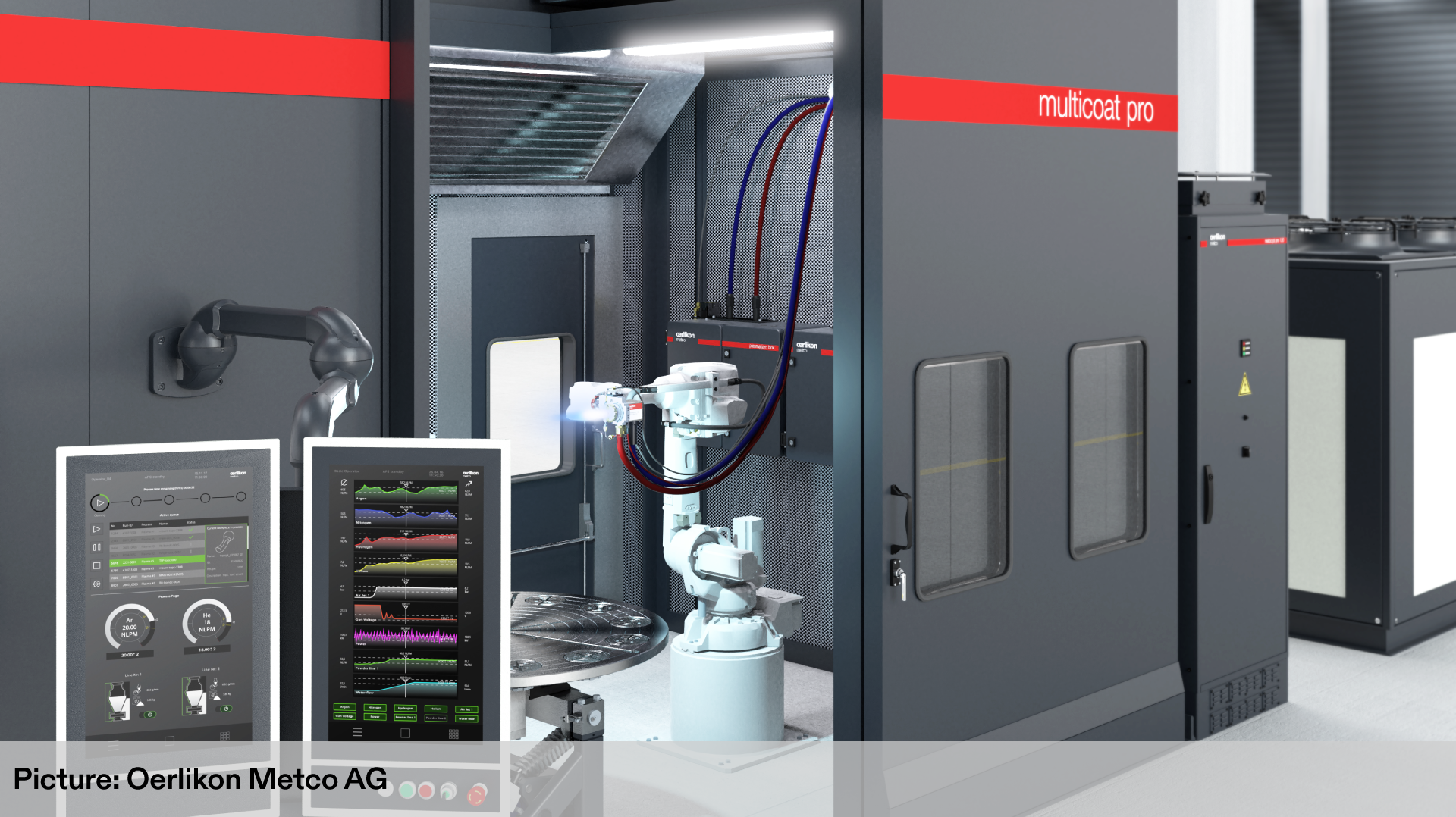

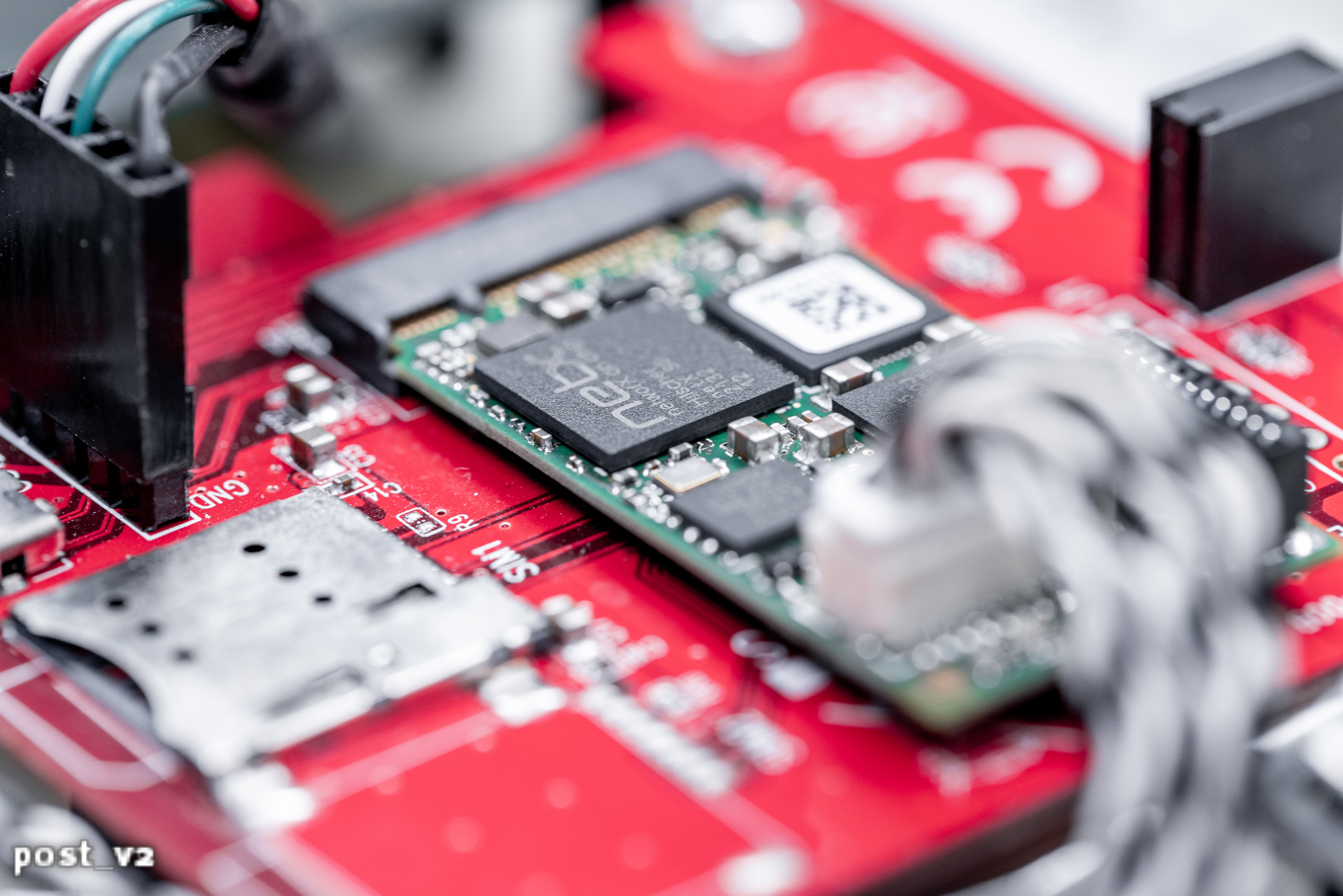

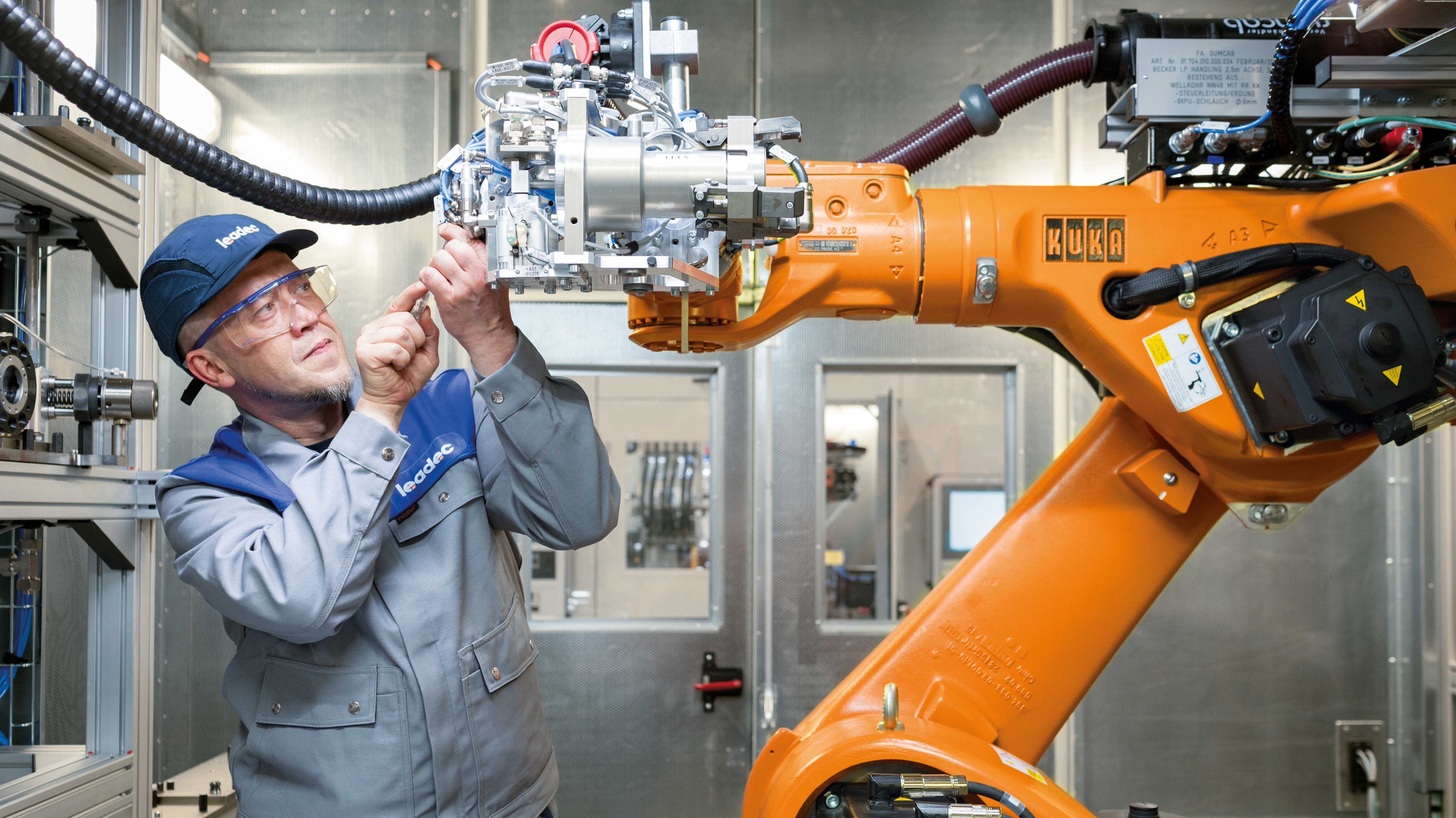

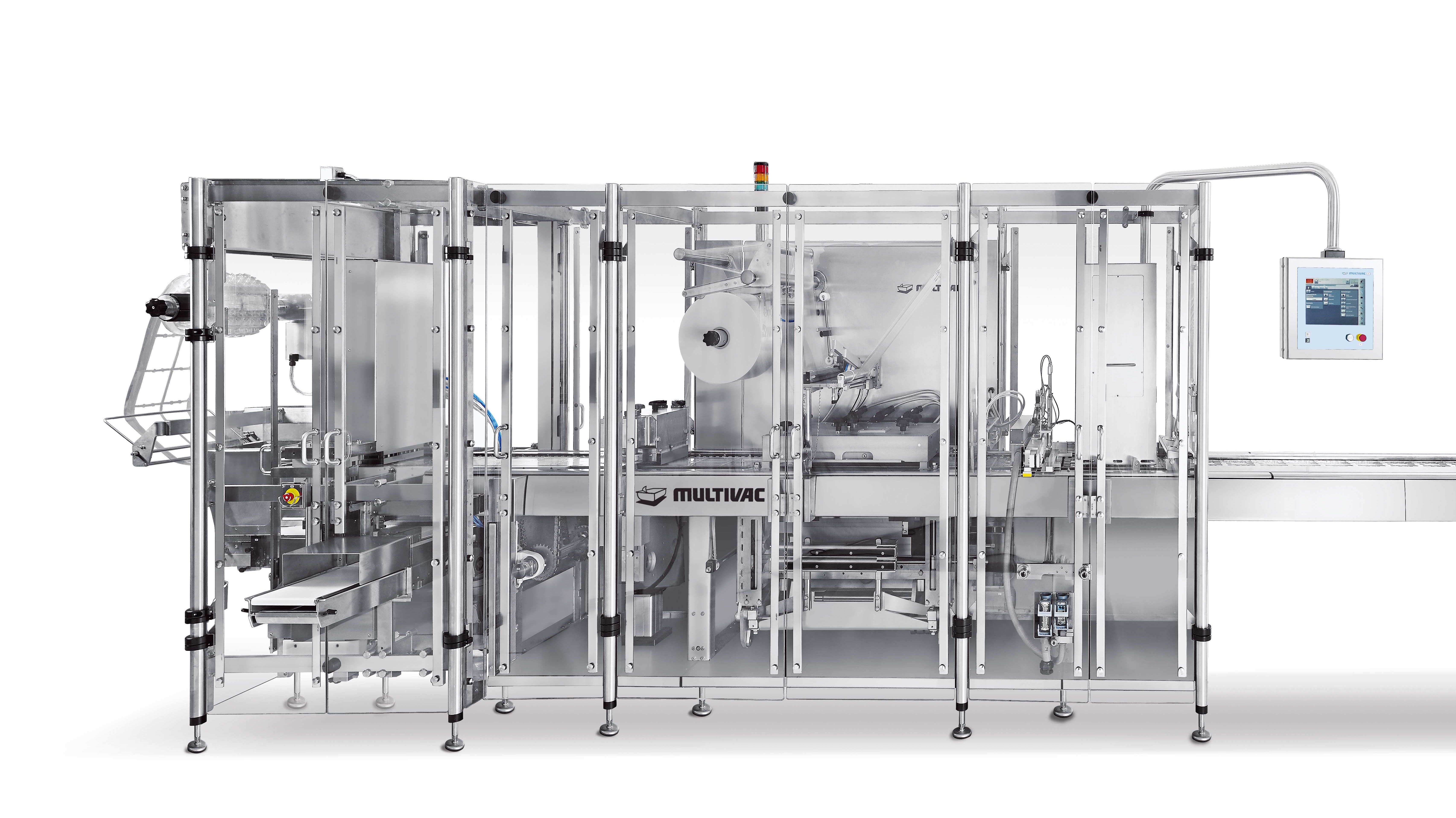

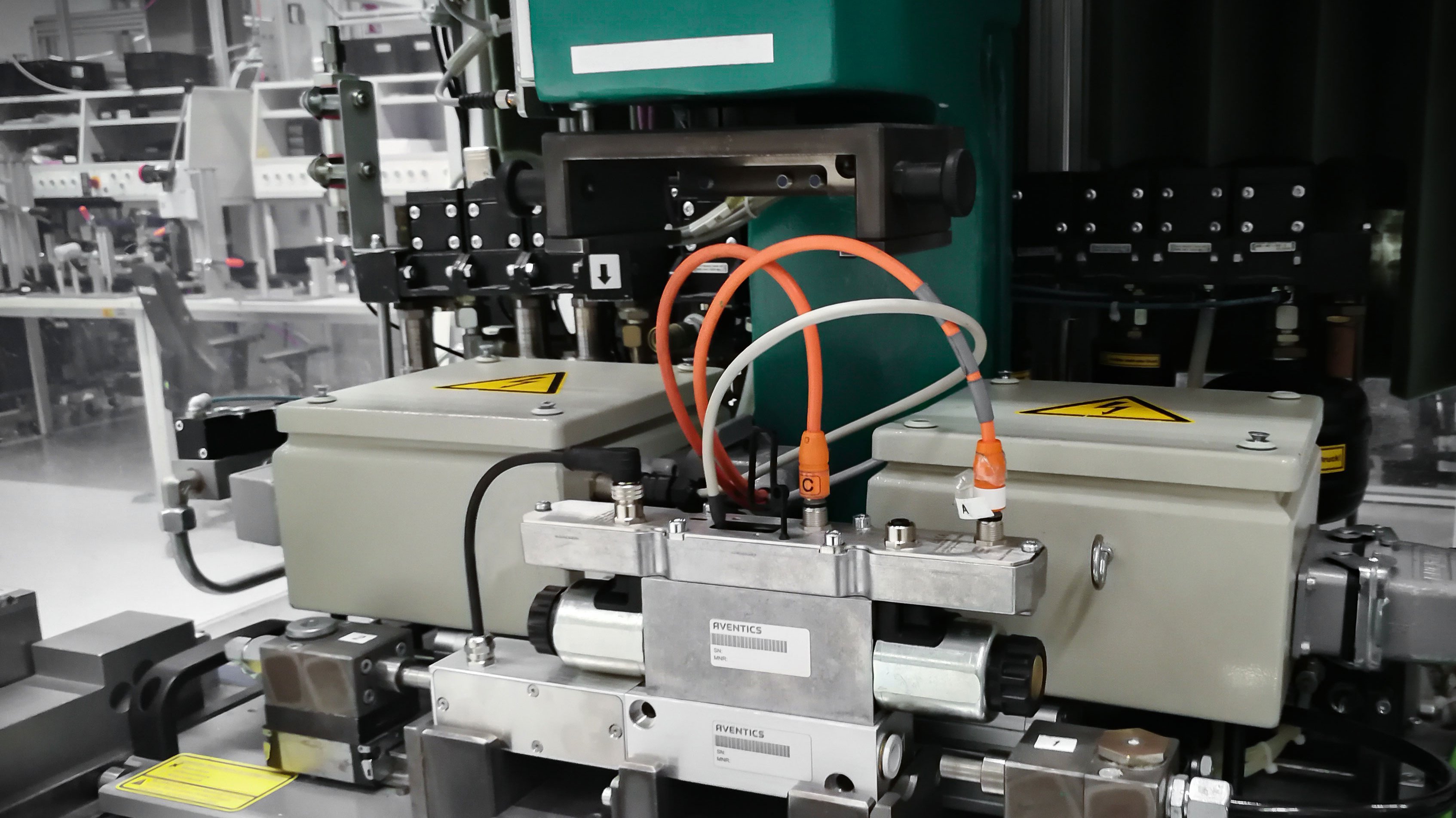

Hilscher is the leading technology and solution provider in industrial communication. With products and solutions from Hilscher, machines worldwide communicate with each other automatically, quickly and securely, so that production and processes run smoothly. From hardware to the cloud, Hilscher makes Industry 4.0 possible. This opens up completely new possibilities in connectivity, giving customers access to a wider market.

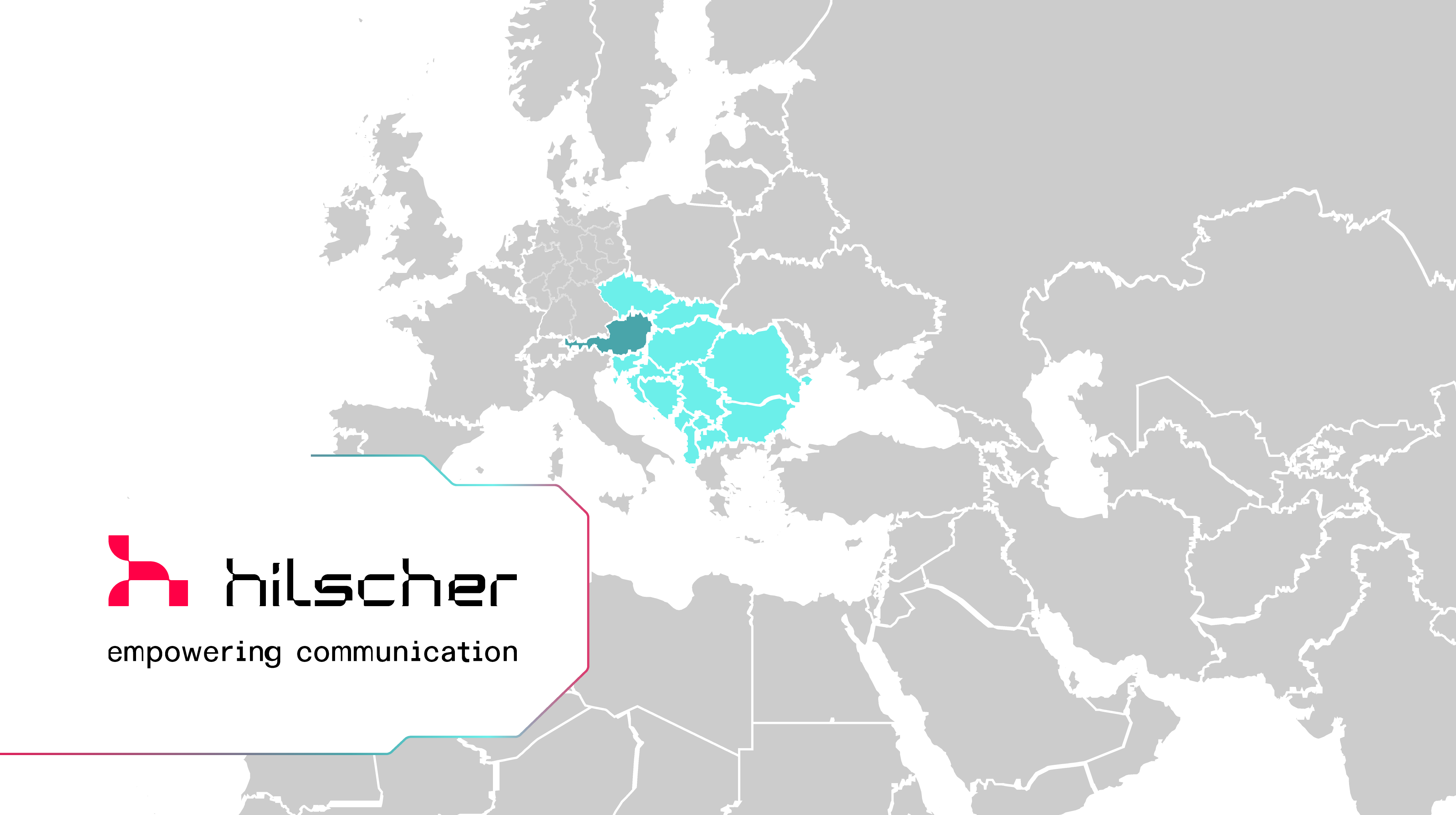

Hilscher was founded in 1986 in Hattersheim am Main and has since developed into an internationally active company with more than 400 employees at 13 locations worldwide.

From turn-key products to highly integrated solutions and complementary software, Hilscher is your partner for industrial communication. Get an overview of how we can help you take the networking of your machines to a whole new level!

Become part of the Hilscher team and help drive the network integration of machines around the globe. We're always looking for dedicated people who are interested in one of the most disruptive technologies of our time.

We have the answers to your questions – your direct contact to our experts.

For over 35 years the name Hilscher has stood for trendsetting automation solutions. We understand industrial communication like no other and stand behind our customers with innovative solutions and services for integrating their machines into their network.