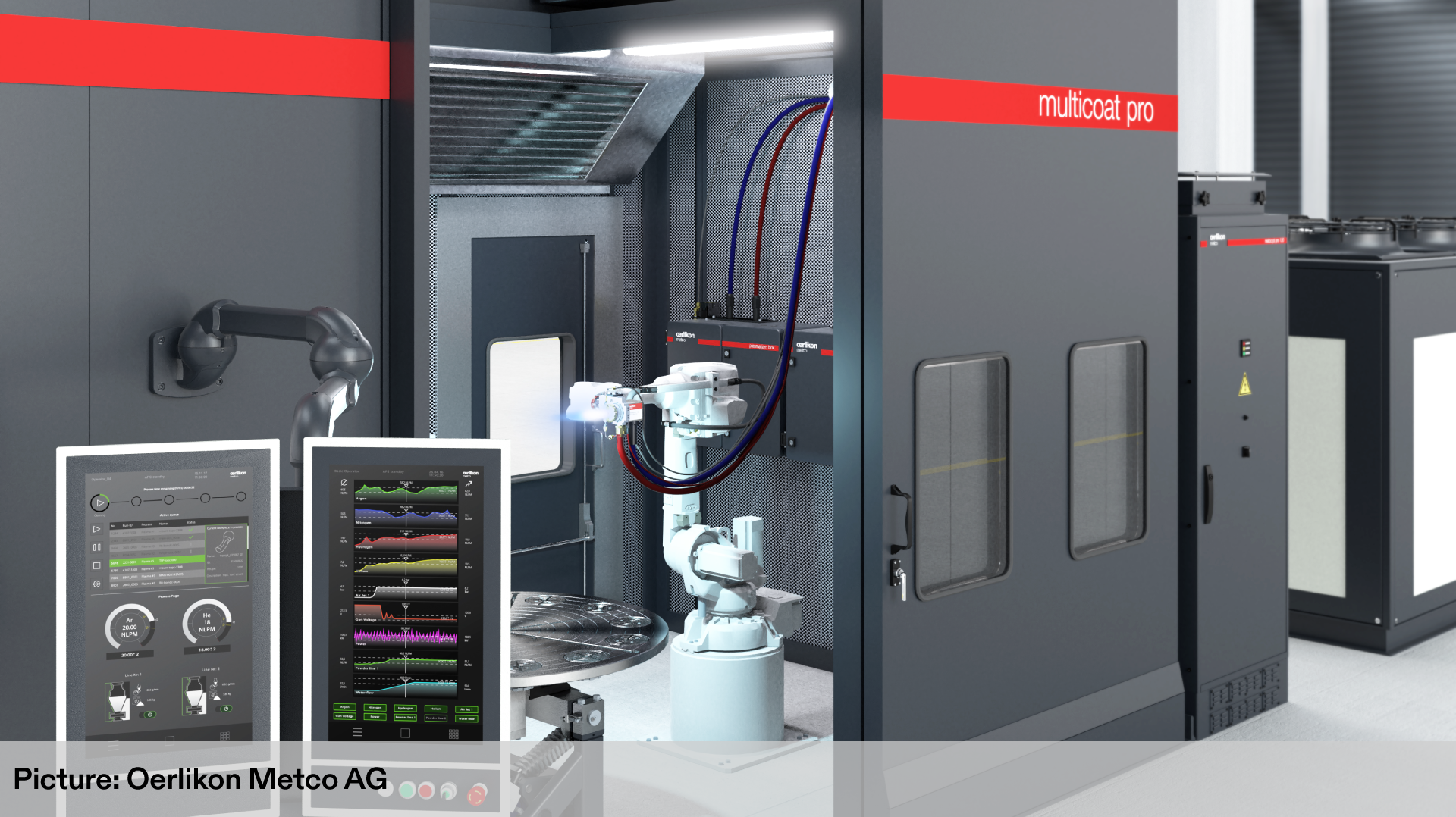

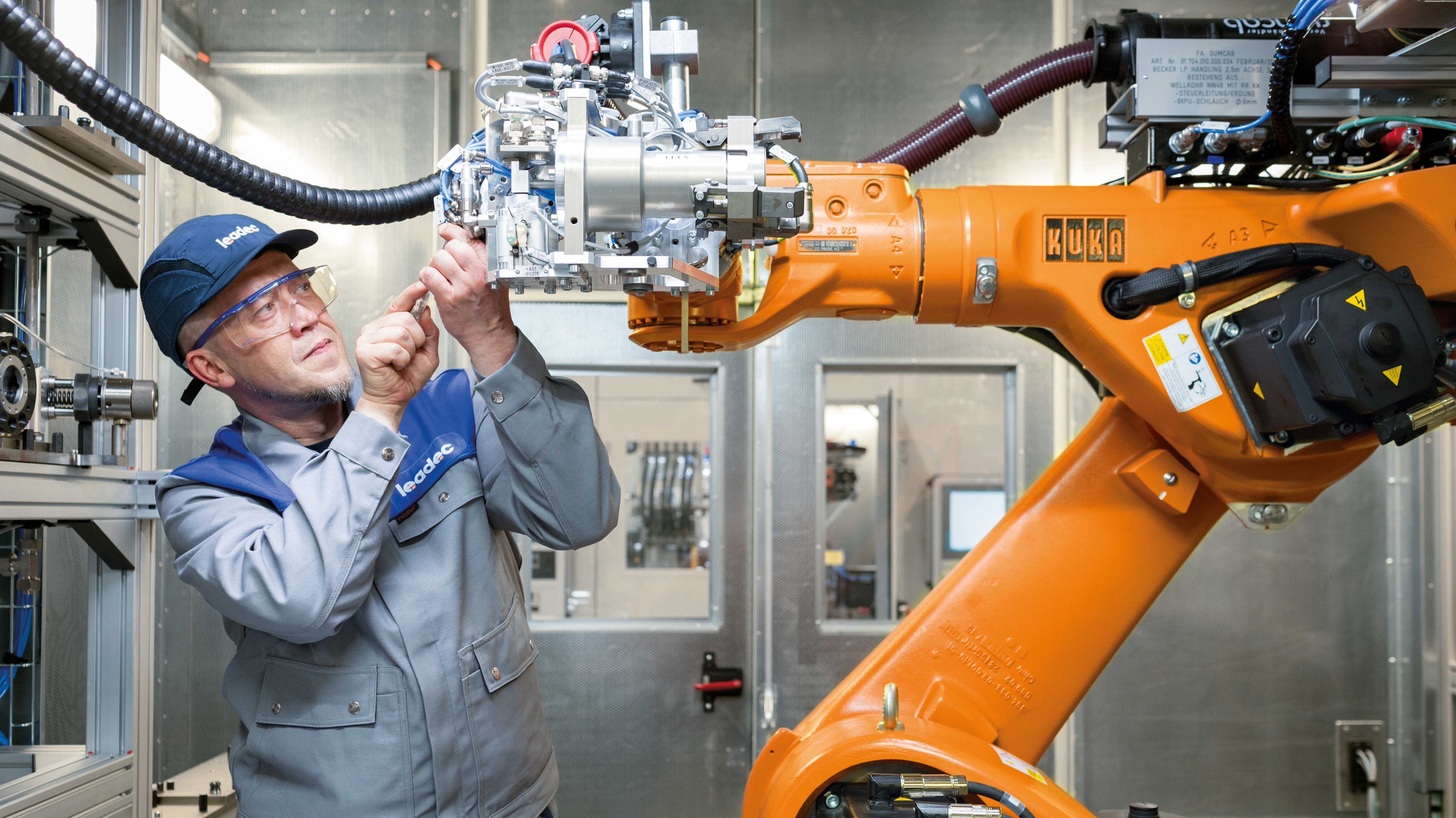

Are you an automation technology manufacturer? Then equip your components with state-of-the-art communication interfaces, ensuring their communication capability. It will enable your solutions to interact quickly, reliably and robustly with controllers, field devices and higher-level systems — whether IPCs, HMIs or actuators such as drives and robots, or even complex applications such as automated optical test systems.

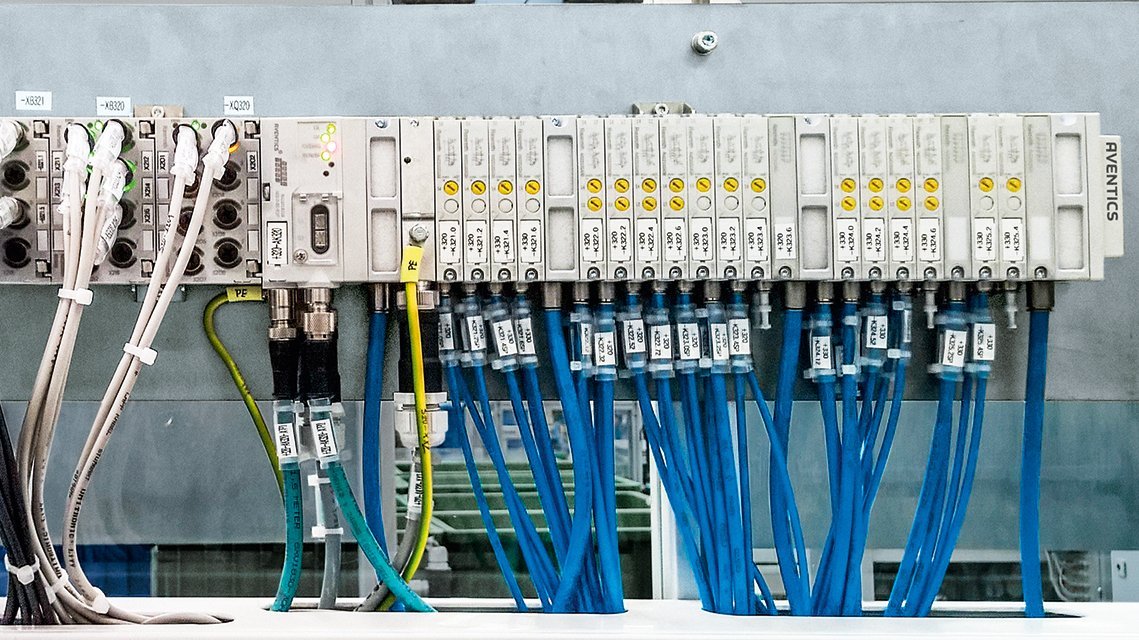

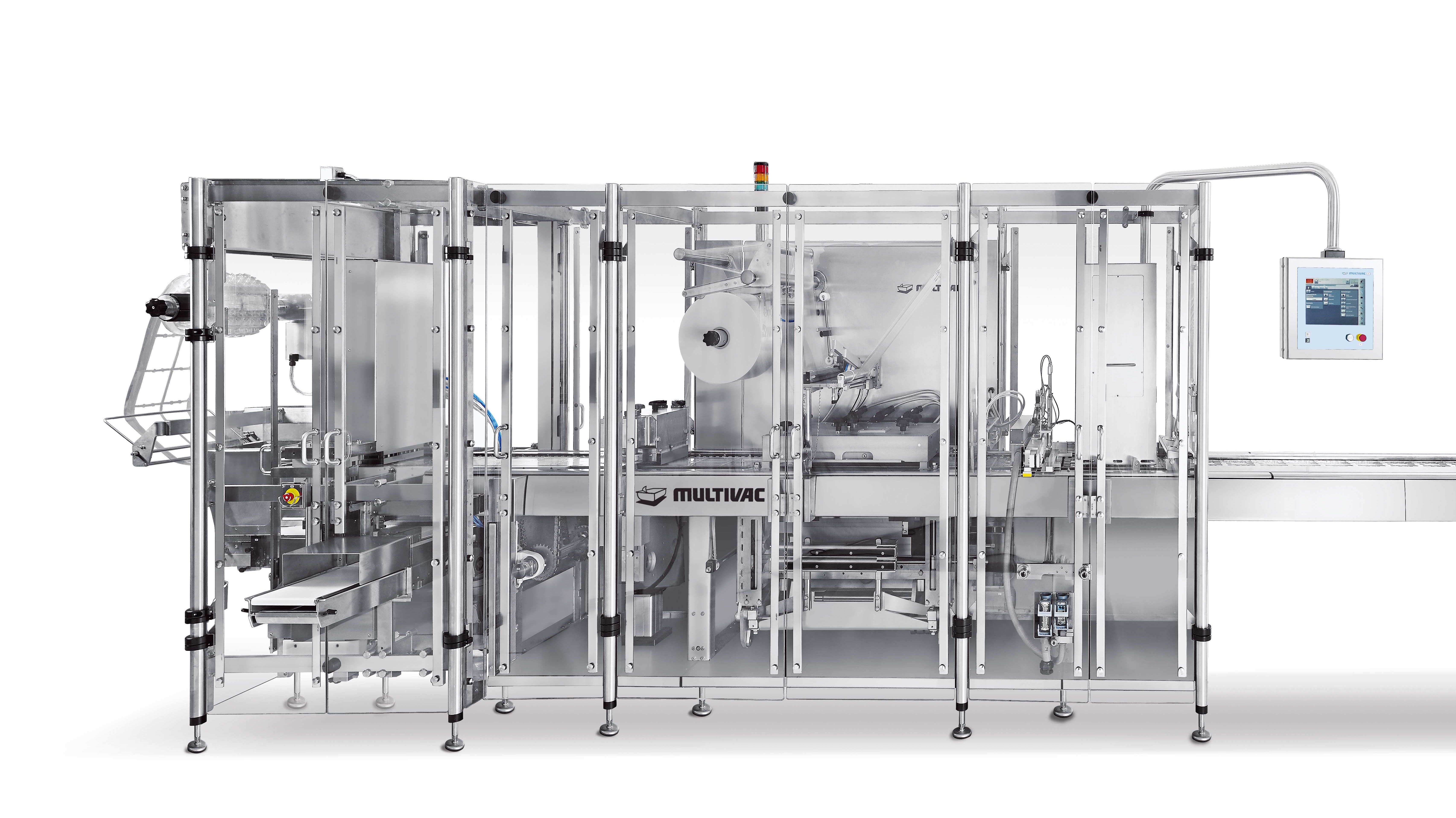

Automated systems also require seamless signal transmission, control and monitoring between different fieldbus and Real-Time Ethernet communication standards. We ensure this with precertified solutions.

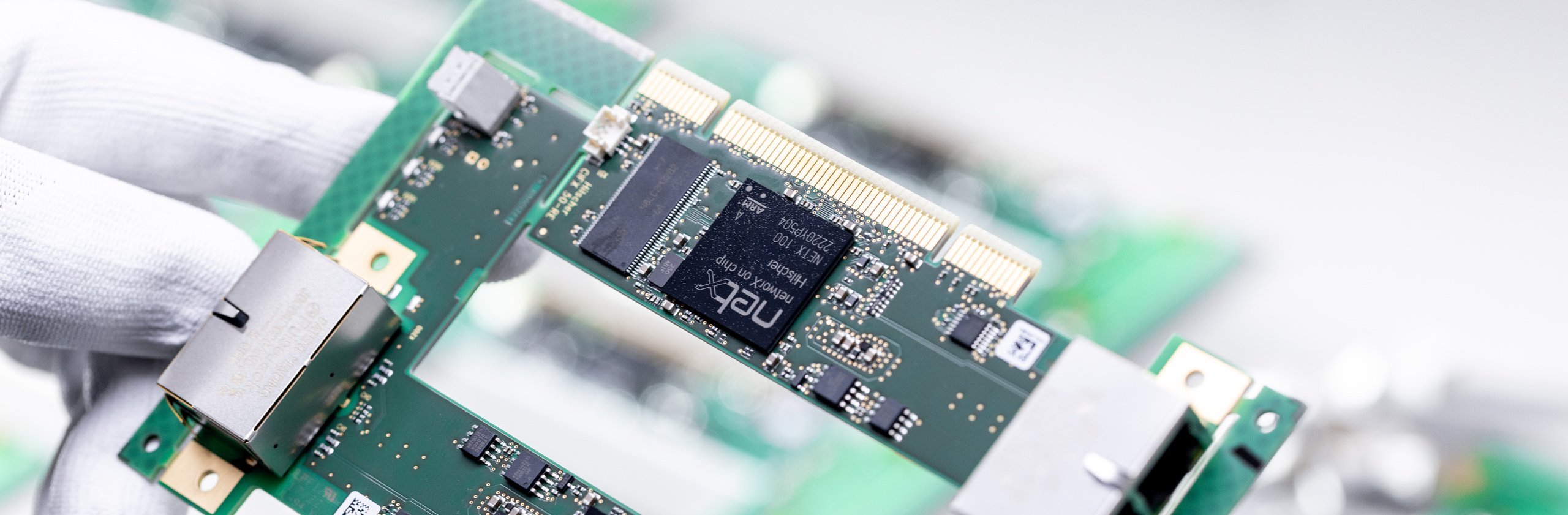

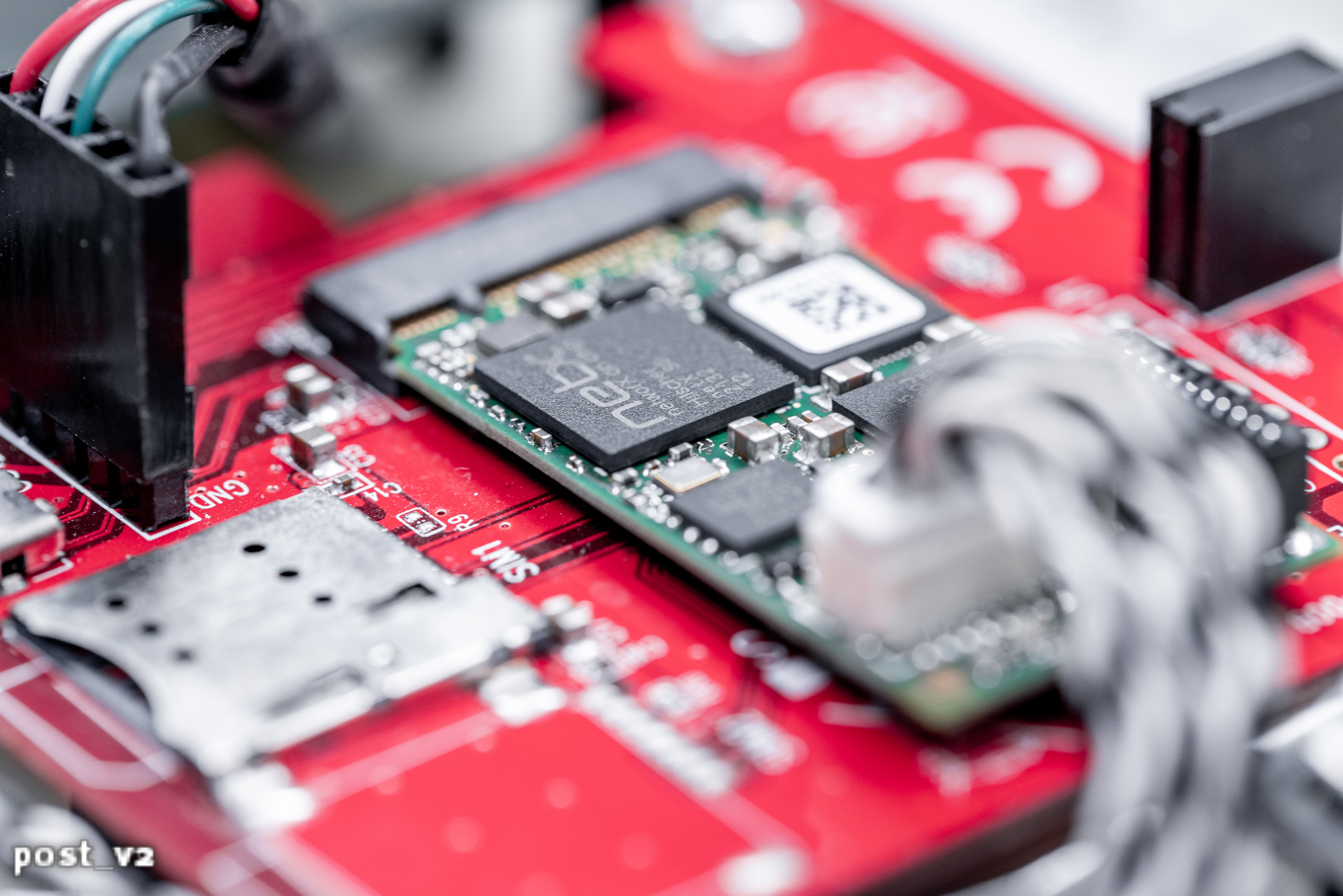

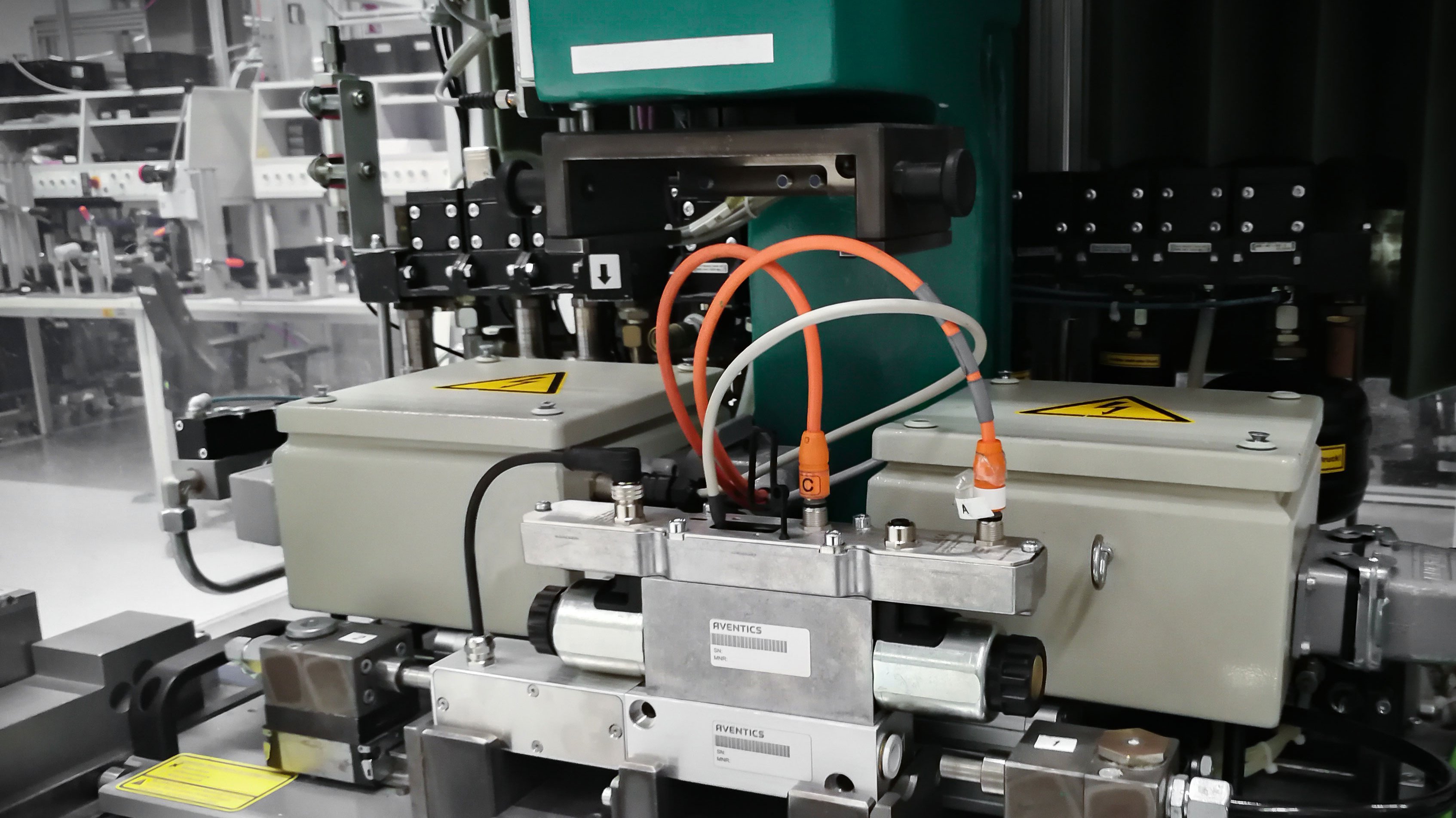

When you choose Hilscher, you turn the high variability of network standards on the market to your advantage. No longer will you have to decide on a single standard—our multi-protocol solutions can cover them all. We deliver a wide range of solutions for industrial communication as well as innovation, know-how and expertise from decades of project experience.