The networking of IT and OT - from field level to the cloud - offers both major advantages and risks for the security of automated production systems. But what about national and international legislation and standards that are intended to structurally increase security in the future? In this article, you can find out what companies need to look out for and where they can get additional input from experts such as the industrial communication specialist Hilscher.

Editor-in-Chief Ronald Heinze (Digital Factory Journal) and our Head of Product Management Indistrial IoT Uwe Schnepf (Hilscher) discuss, how machine and plant data can be made accessible in industrial applications. Read more in our blog!

Many IIoT prototypes fail when it comes to operational implementation. A review by Hilscher and our expert Dr. Andreas Graf Gatterburg on the challenges of operational scaling of IIoT projects. Read more in our blog!

“We make machine data accessible. The user provides the process knowledge.” This is how Dr. Marek Meyer, Product Manager of Industrial IoT at Hilscher, envisions the ideal assignment of roles for a successful IoT infrastructure that delivers immediate tangible results. Read more in our blog article.

How are digitization projects in the field of Industrial IoT successfully implemented? With the netFIELD operating system and the netFIELD.io cloud platform, individual sensor-to-cloud solutions can be developed. Learn more in our blog!

Blog

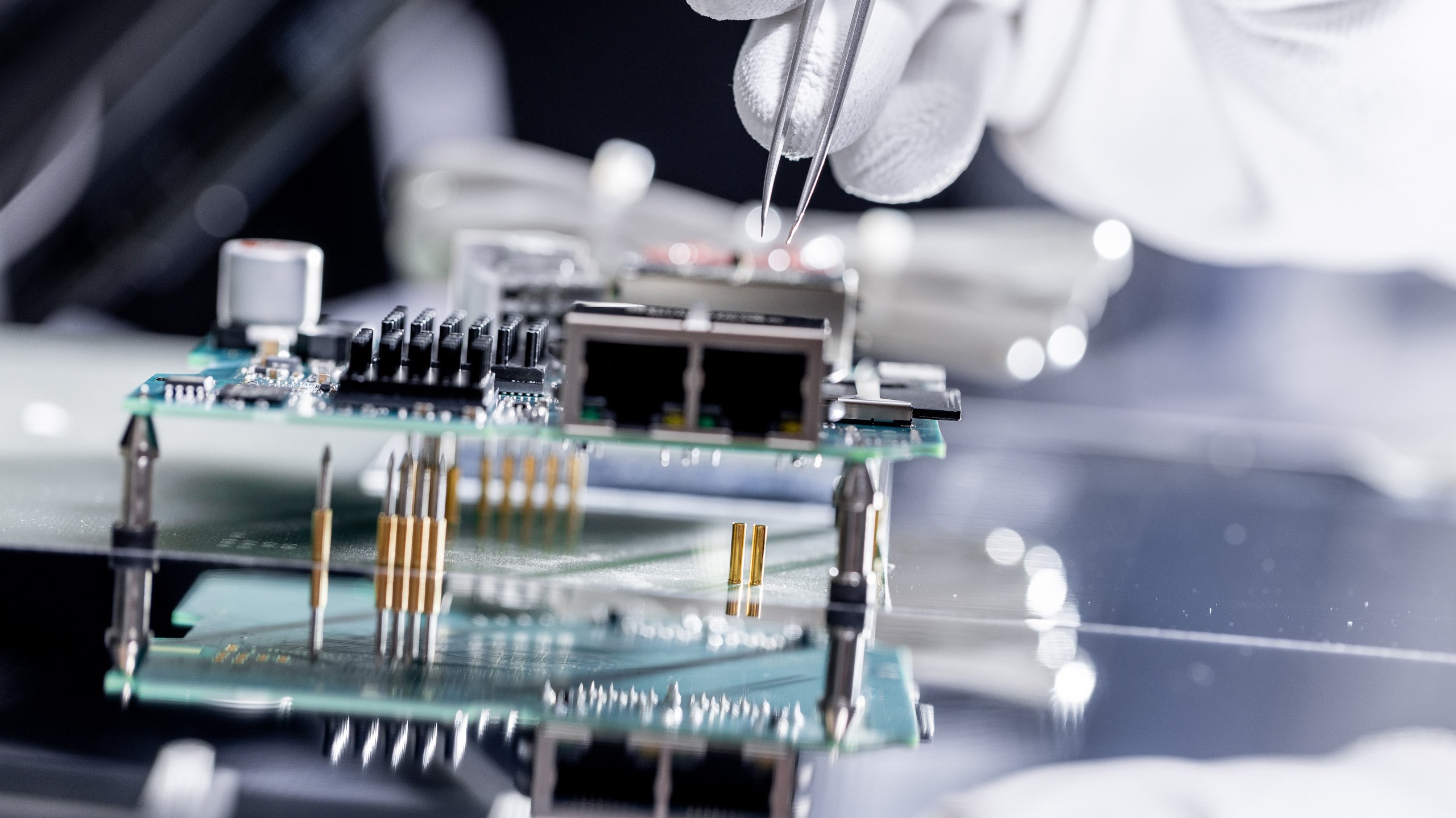

The current chip crisis presents the semiconductor industry with one of its biggest challenges of recent decades.

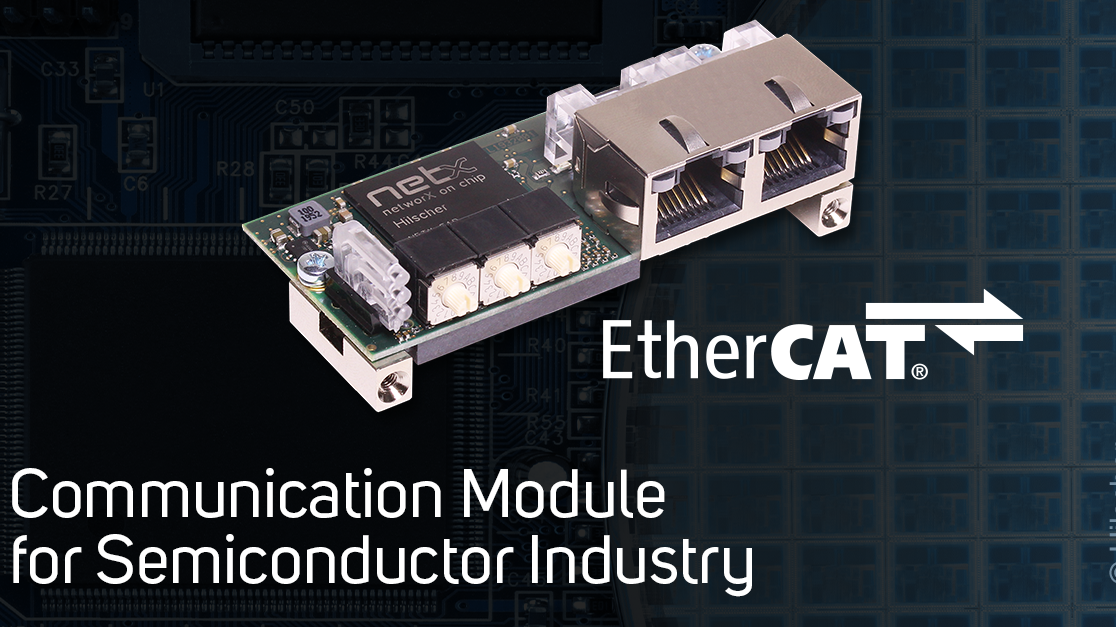

The semiconductor industry relies on state-of-the-art technology when planning new production facilities. Thanks to the comX 51CA-RE\R machine builders are now finally able to fully concentrate on the development of their applications when designing their tools for the semiconductor industry.

The comX communication module was developed to equip automation devices with a network interface. Here, all communication tasks are executed autarchically on the module - independent of the target platform processor.

The use of an embedded module has always been a sensible alternative to the traditional and complex Design-In process of a chip. For more than 25 years, Hilscher has been a leader in factory automation with embedded modules for industrial communication and that with a consistent concept.

The future prospects for the semiconductor industry are quite positive, with a projected growth of around 9% in 2022. However, the industry is repeatedly faced with supply bottlenecks due to the effects of the ongoing coronavirus pandemic, amongst other factors. By developing a new comX communication module, especially suited for the semiconductor industry, Hilscher is supporting to cope with the current situation.

Part 4 of our blog series about Single-Pair-Ethernet: A lot of work is still ahead of the industry to get open questions resolved in terms of system adoptions, standard integration and leveraging benefits in relevant use cases. How do the future prospects of SPE look like?

Read the article!

Part 3 of our blog series about SPE: Factory automation networks are already largely based on Ethernet standards today. However, the adoption of Ethernet in the process automation field is still in progress. How does SPE affect these two industrial areas?

Read the article!

Part 2 of our blog series about SPE: While the idea to enable IP based networks down to the sensor level is obviously beneficial, the question is, how SPE is able to deploy in the focused devices and installations.

Read the article!

Part 1 of our blog series about SPE: Single-pair Ethernet, as a new initiative to enable IP based networks to each sensor, adds value through thinner cabling, small footprint plugs and connectors and less space requirements. For that reason, it is suitable to replace numerous existing fieldbuses in the sensor and peripheral area by integrating sensors directly to IT- and Cloudsystems.

Read the article!