Despite promising results, many prototypes and pilot projects ultimately fail due to their implementation into serial production. The reasons for the failure are different. On the one hand, scaling costs for digitization projects are often underestimated when companies develop such solutions for the first time. Development work is complex and involves many different experts from very different areas. The skills required are not always available in a company and are difficult to obtain on the labor market. If, on the other hand, prefabricated solutions are used, the costs for commissioning will be reduced. However, the customization options for the user remain very limited.

Increasing complexity makes demands rise

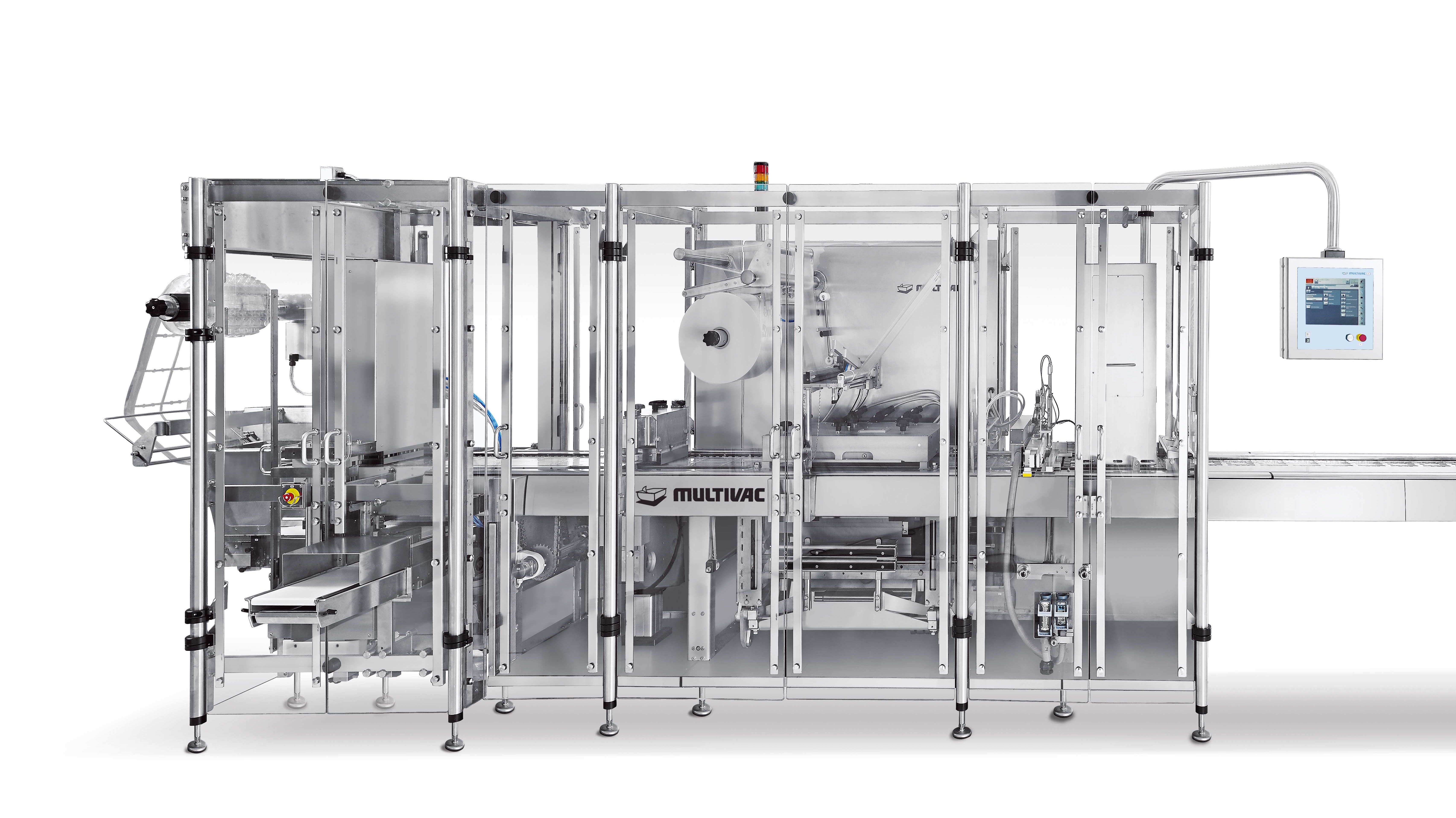

As part of retrofitting projects, sensors are subsequently installed at the appropriate locations in your systems, for example, in order to be able to measure specific parameters or control processes better. From position sensors, fluid sensors and encoders to image processing and safety-critical parameters – as processes become more complex, the demands placed on the data collected, their management and processing also increase.

In addition, meaningful transmission paths for the data must be evaluated. For some applications, wireless technologies are already in question, while in other applications, a classic fieldbus may still be the measure of things. However, new technologies such as Single Pair Ethernet (SPE) are already in the starting blocks, which will once again significantly influence modern industrial production.

In addition, while for prototypes all data is often stored on a central server and analyzed there for the acquisition of insights, this architecture is not optimal for productive operation. In series operation, data processing must be carried out at least partially distributed in edge devices close to the machines and plants. Edge computing can reduce the amount of data and latency transmitted and increase the reliability of the overall system.

This distributed setup of Smart Edge components is underestimated by many companies in the prototyping and pilot phases. This, we observe, creates additional hurdles and challenges in the transition to series production and operational scaling at a late stage.