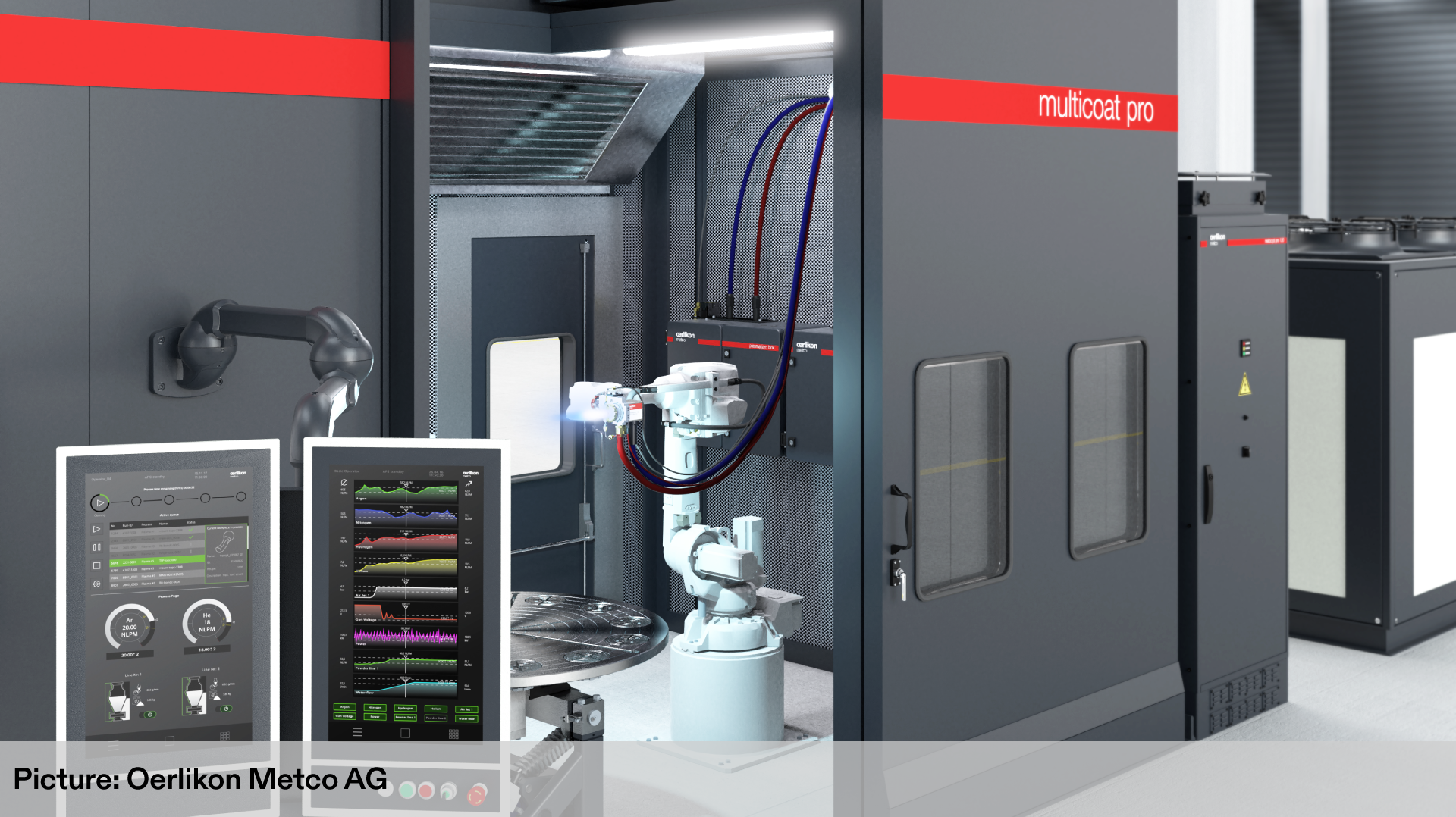

Optimizing business processes in today's IoT environments requires the processing of extensive data. One way to do this is by graphically displaying the collected information, e.g., machine status or current productivity numbers, to gain valuable insights. For plant operators and machine manufacturers, recording irregularities and finding ways to improve efficiency is a crucial factor in ensuring smooth production processes.

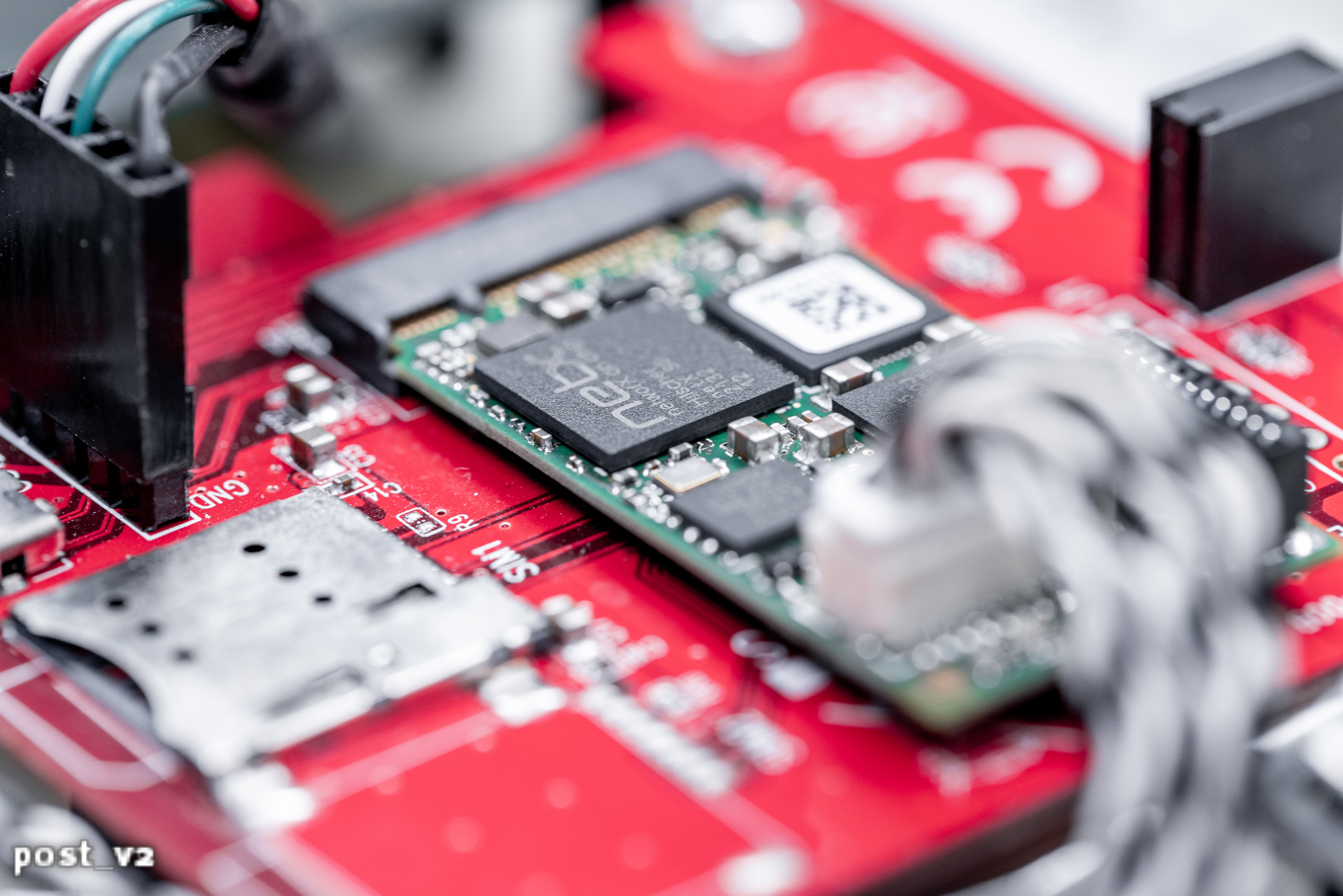

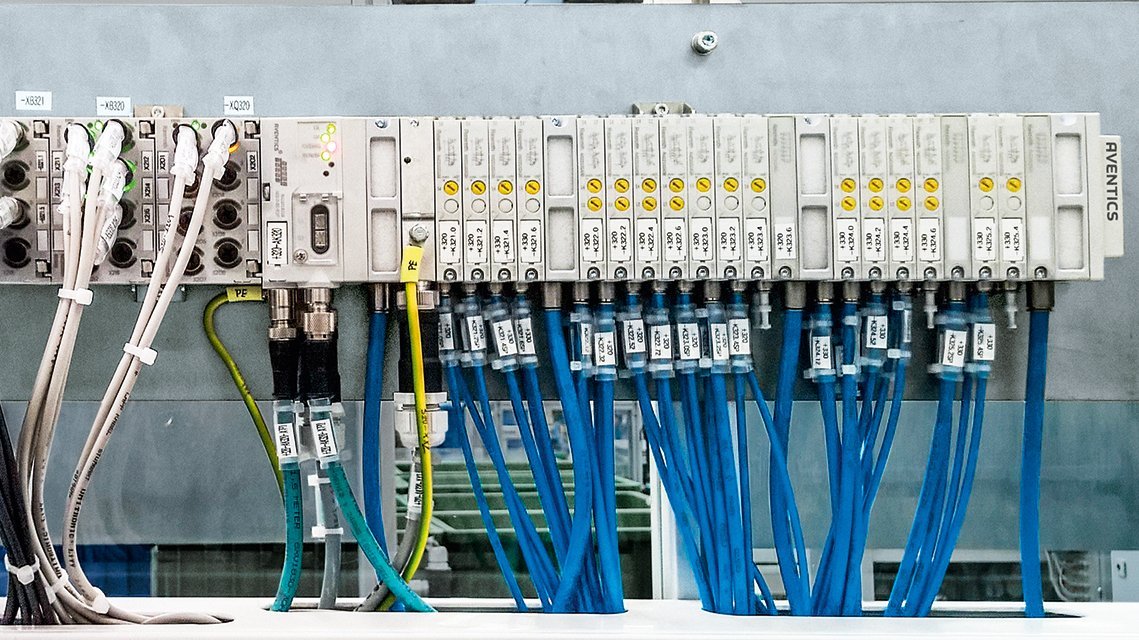

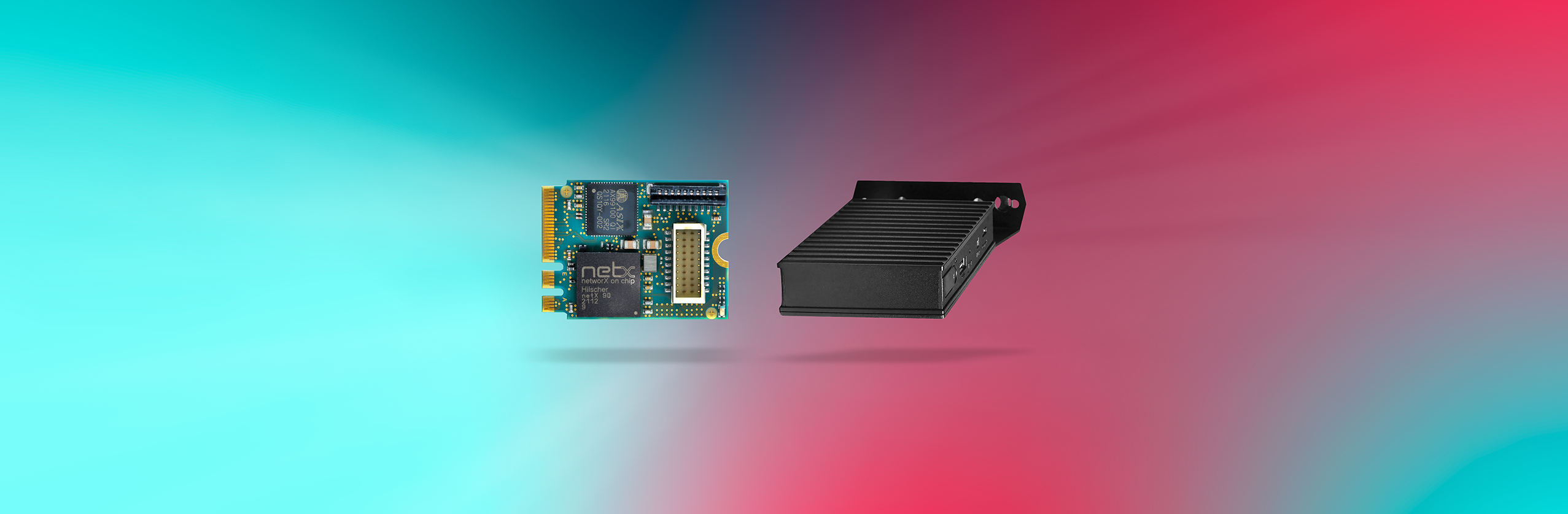

With modern cloud solutions, you can collect and centralize your data across multiple locations and online services and then graphically represent them in a meaningful way. This allows you to keep a close eye on important parameters and to make any necessary changes to your processes whenever necessary. Our netFIELD portfolio gives you a comprehensive solution covering all your needs from connecting sensors to offering helpful dashboards in the cloud.