With more than 35 years of experience, VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH, headquartered in Wiesbaden (Germany), develops, produces and supplies first-class machine vision systems. With VIRO WSI, the company offers a leading technology for automated weld seam inspection. The optical inspection system consistently inspects weld seams on workpieces 100% objectively and reliably based on previously defined quality

criteria and replaces the manual, and therefore error-prone, visual inspection.

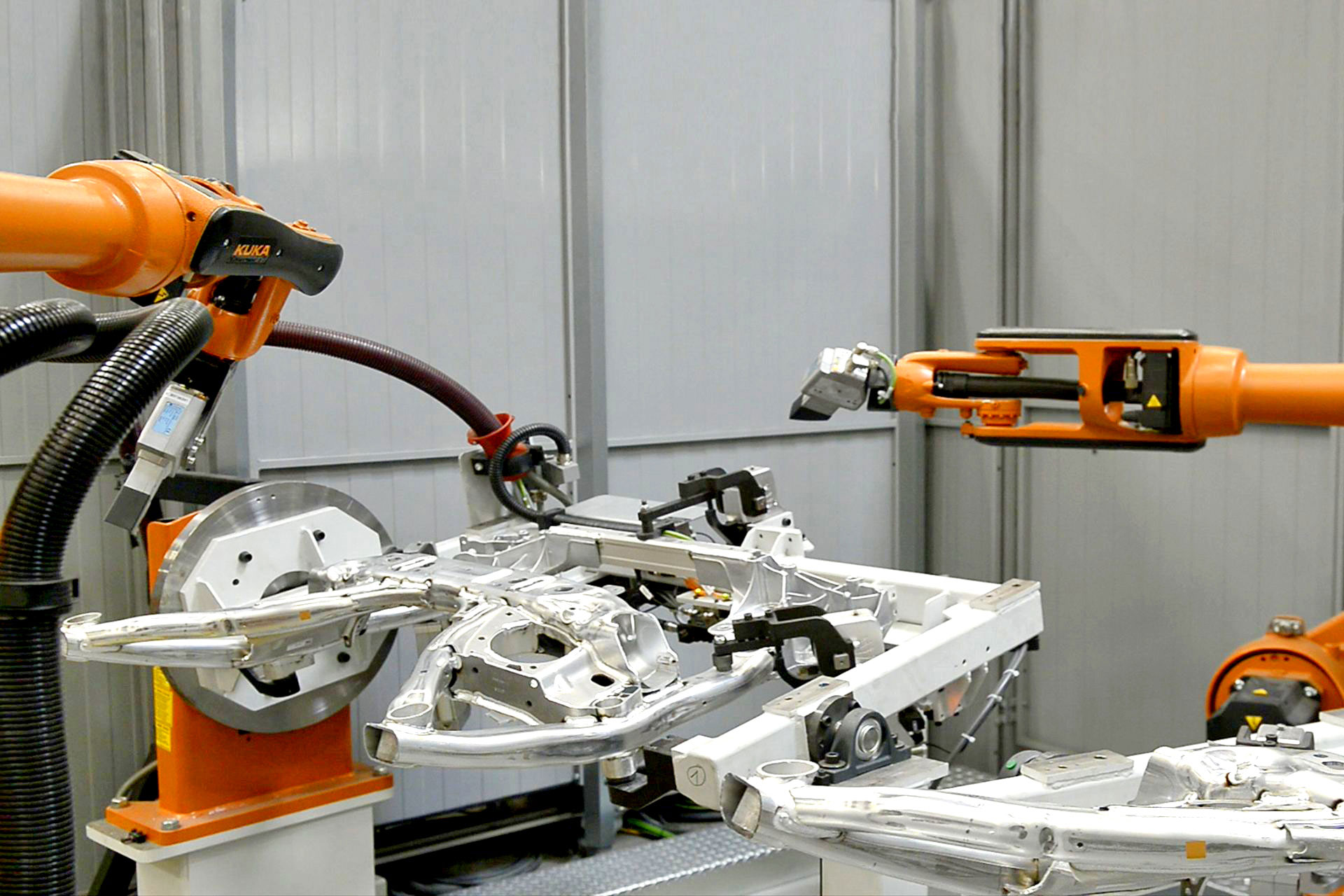

In order to quickly identify defective welding seams, the system requires a constant real-time coordination between the visual inspection and the handling robot.

The major challenge is to keep the overall cycle time for acquiring the 3D information of every weld seam, analyzing the recorded pictures, and transferring the resulting information to the machine’s controller to a minimum.

That process ensures that the robot always reworks the workpiece exactly where the weld seam is defective.

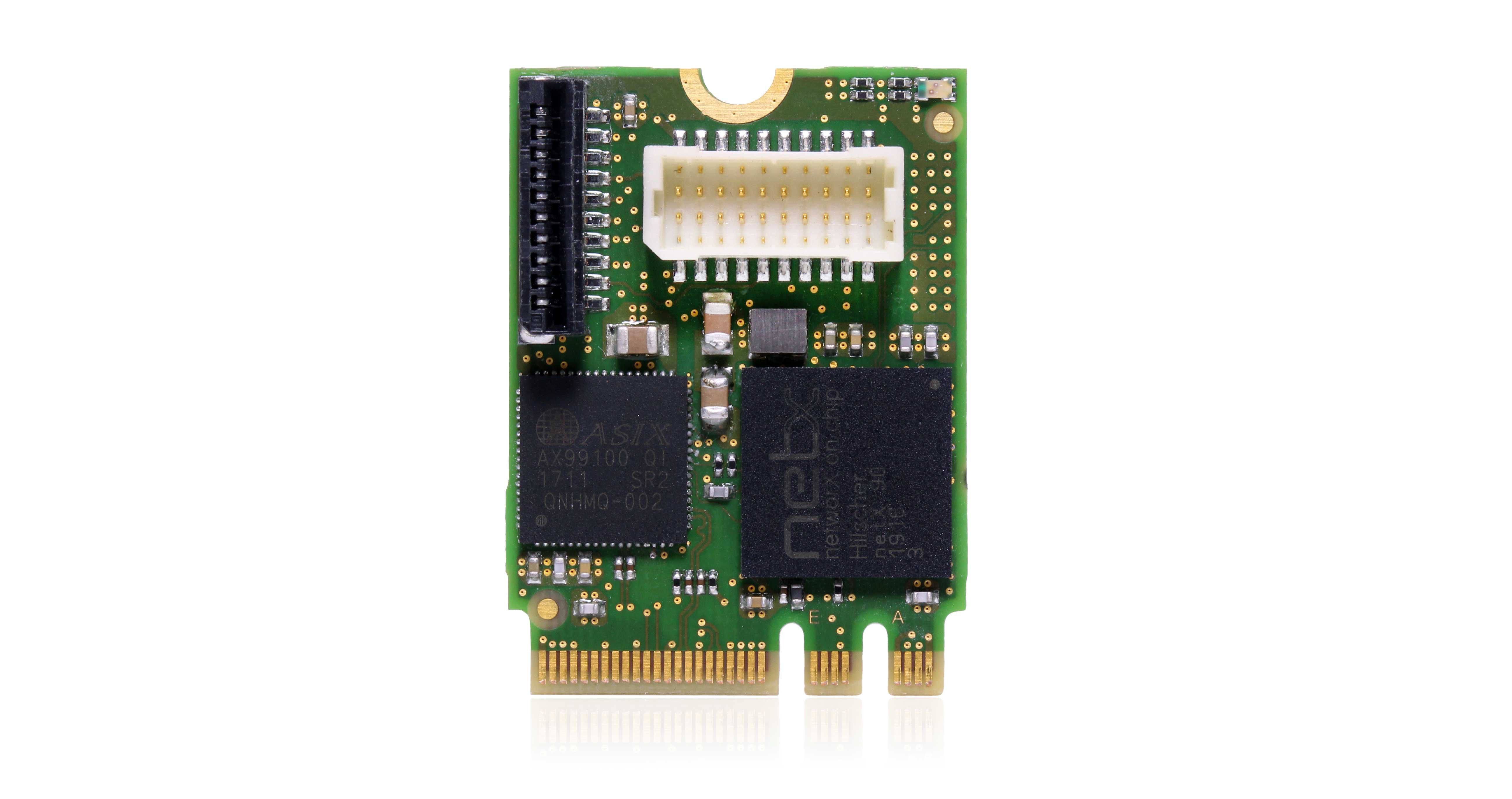

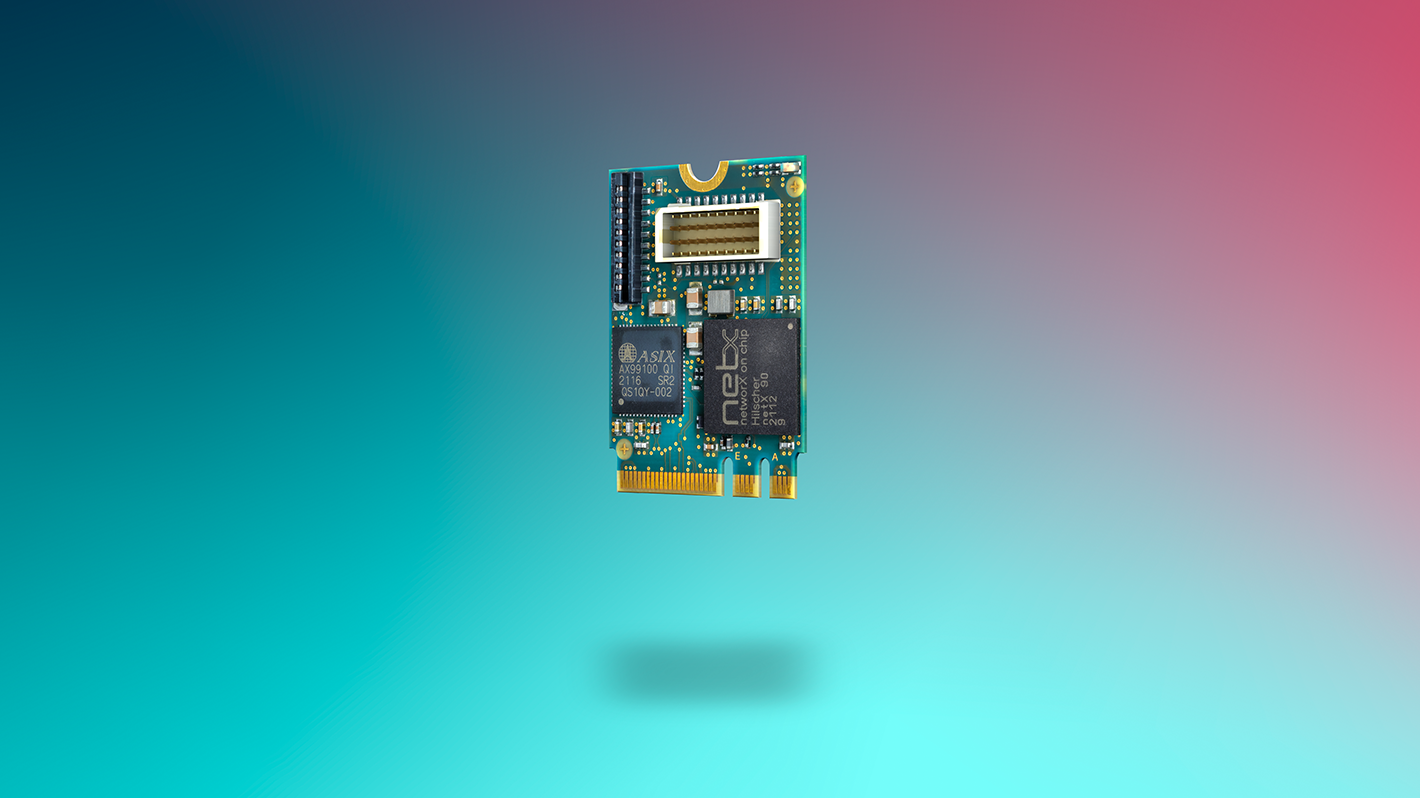

To meet the challenge of integrating VIRO WSI into machines and plants, being independent of the customer’s preferred network protocol, VITRONIC integrates Hilscher’s PC-Cards and is strongly convinced of the new generation’s benefits – especially of cifX M.2 2230 Key A+E.