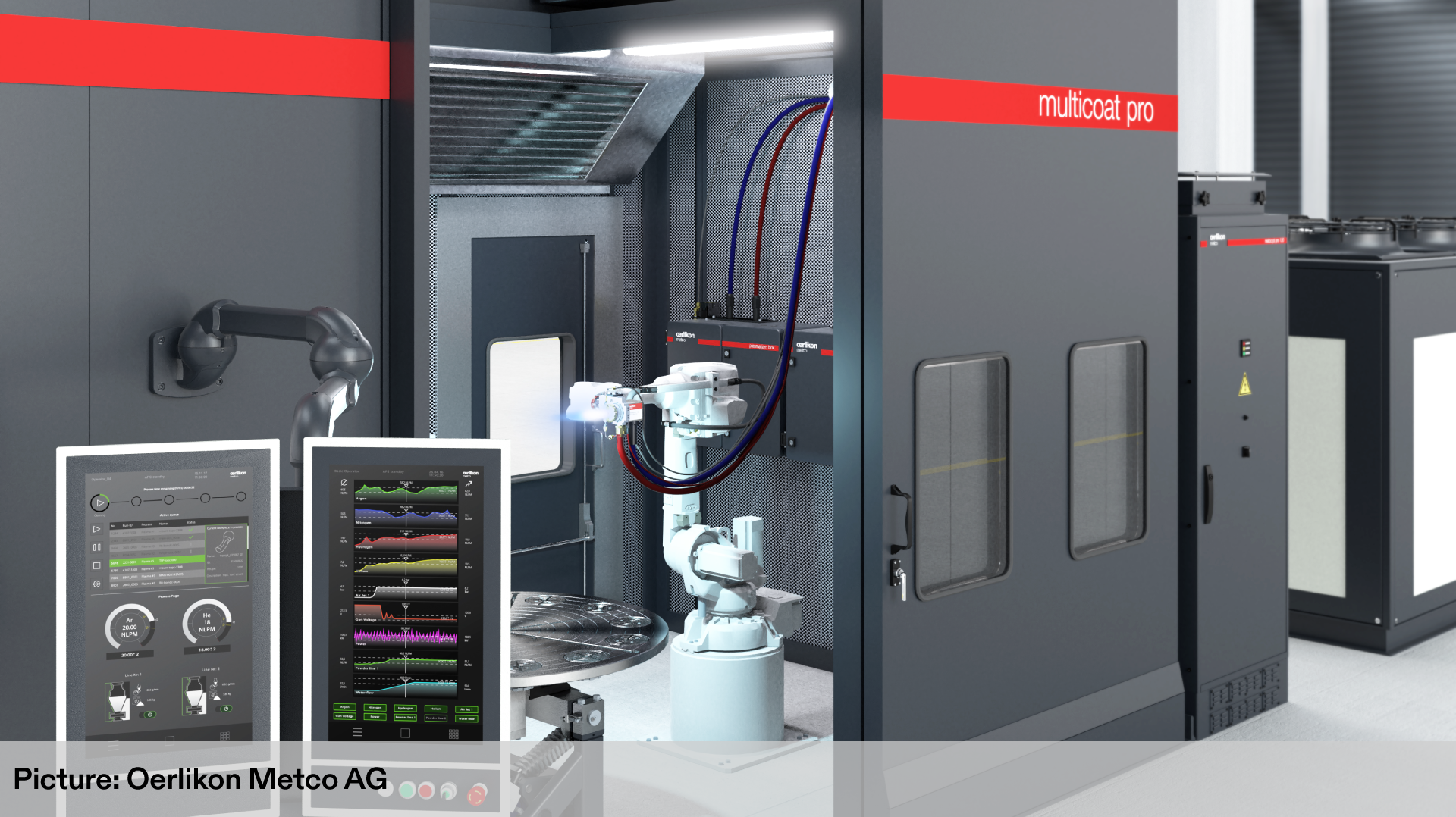

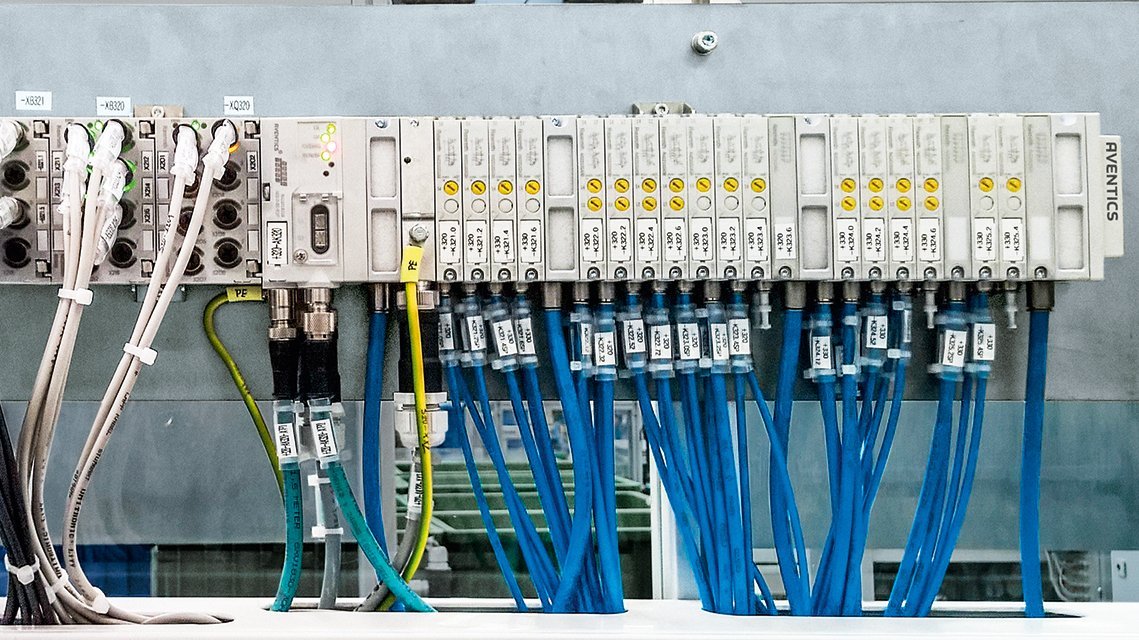

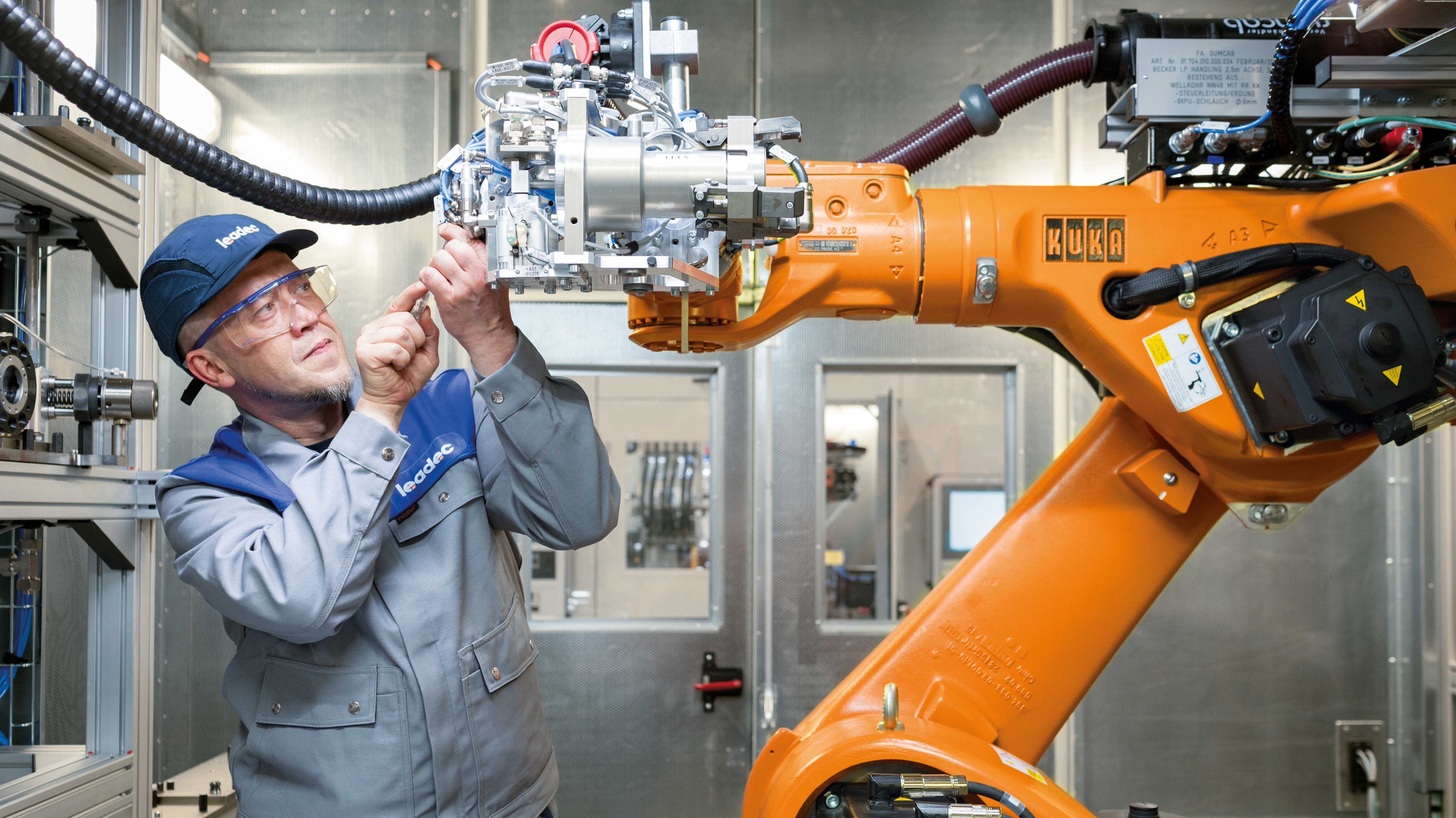

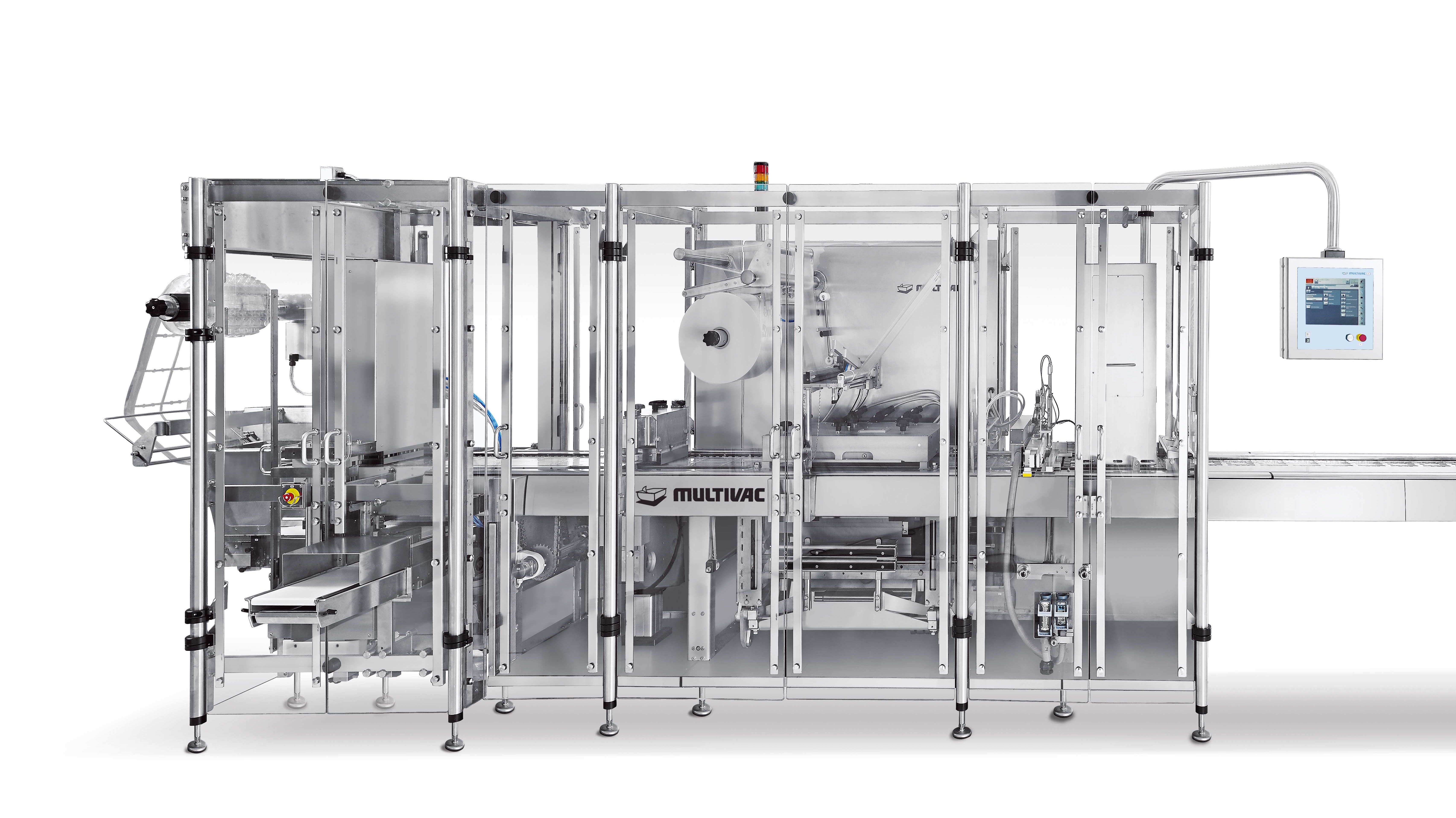

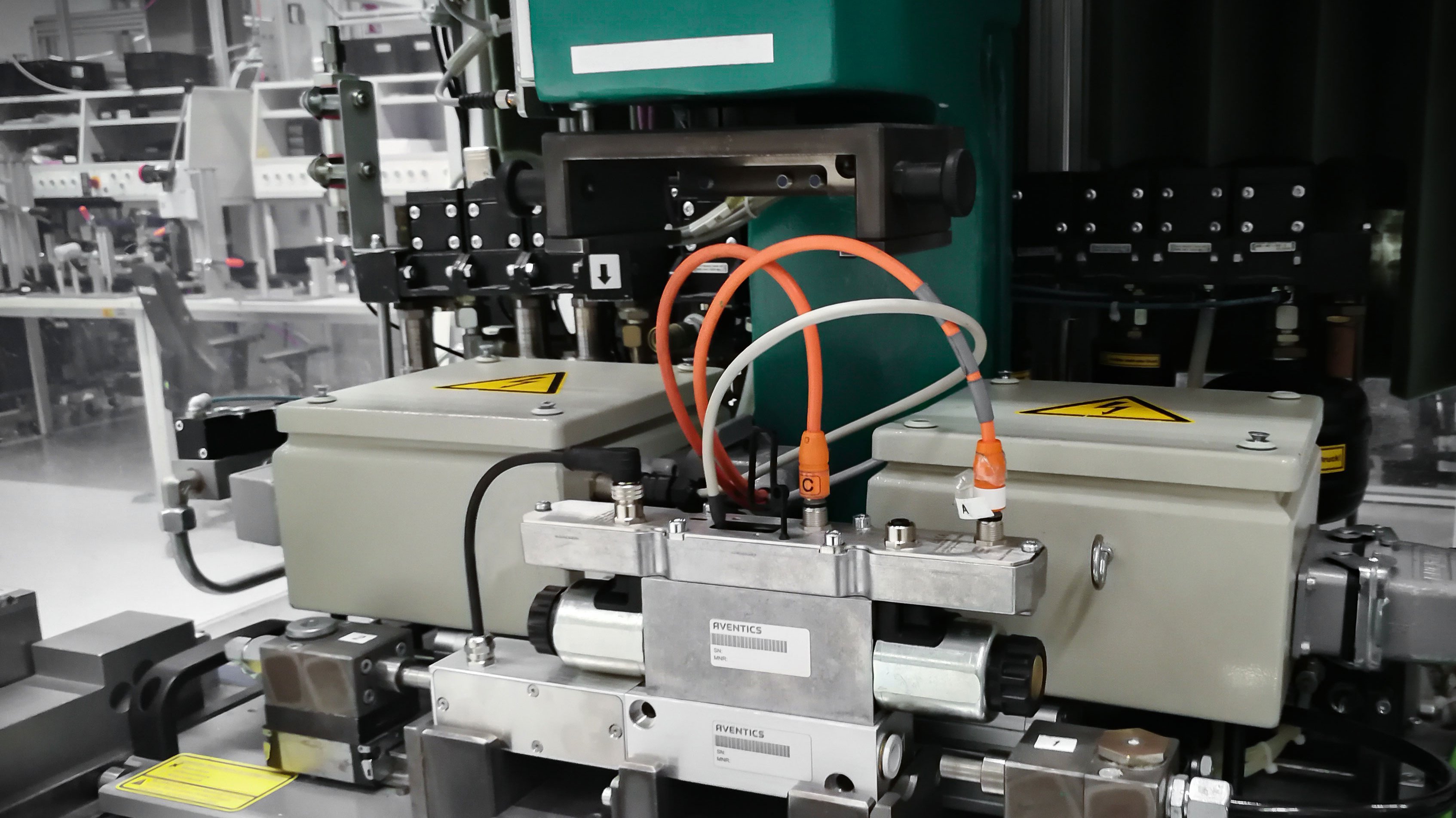

Data acquisition and analysis tools as well as the IoT allow you to tap into the full potential of your production data for a more efficient operation of your production plant. Irregularities in the production processes and unplanned maintenance work cause production downtimes and result in high costs. As a specialist in industrial communication technologies, our range of products and services give you the tools you need to keep your production up and running.

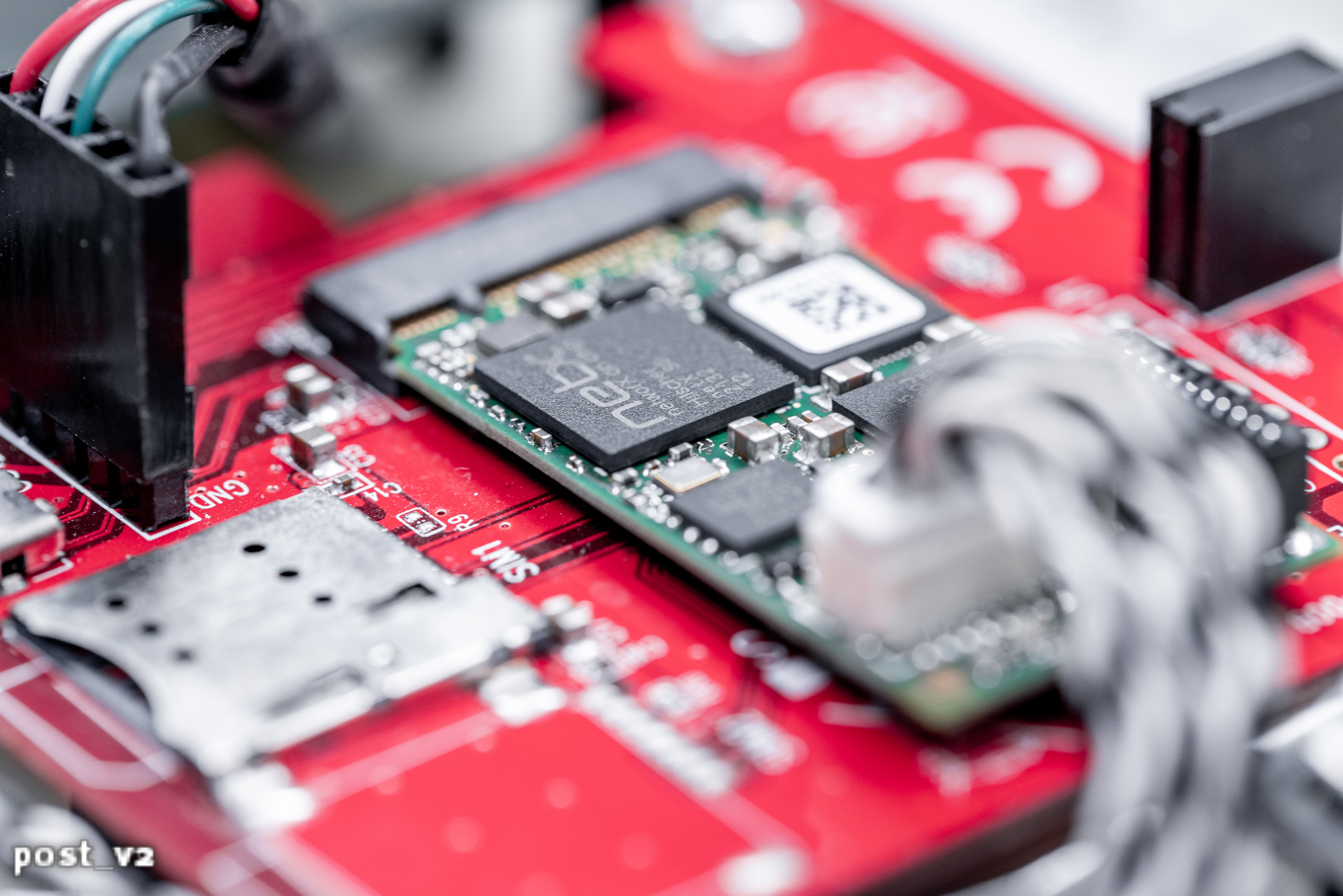

We offer products for passive Ethernet telegram recordings and for continuous diagnostic access points in the field. We also offer netFIELD, a hybrid cloud and edge ecosystem that equips your machines and plant equipment with IIoT functionality. Our netFIELD Cloud, the user-friendly netFIELD portal, dedicated software, and scalable gateway hardware provide a solid foundation for Industry 4.0 services for you and your customers. This allows you to aggregate extensive data from your distributed devices regardless of their location, so that you can optimize your processes. By remotely monitoring your equipment and deploying software containers to your edge devices, you're able to create many new benefits.