The NORD DRIVESYSTEMS Group and its 4,100 employees develop, produce and market drive technologies. NORD has 48 subsidiaries in 36 countries as well as additional sales partners in more than 50 countries, making it one of the leading international full-range suppliers in the industry.

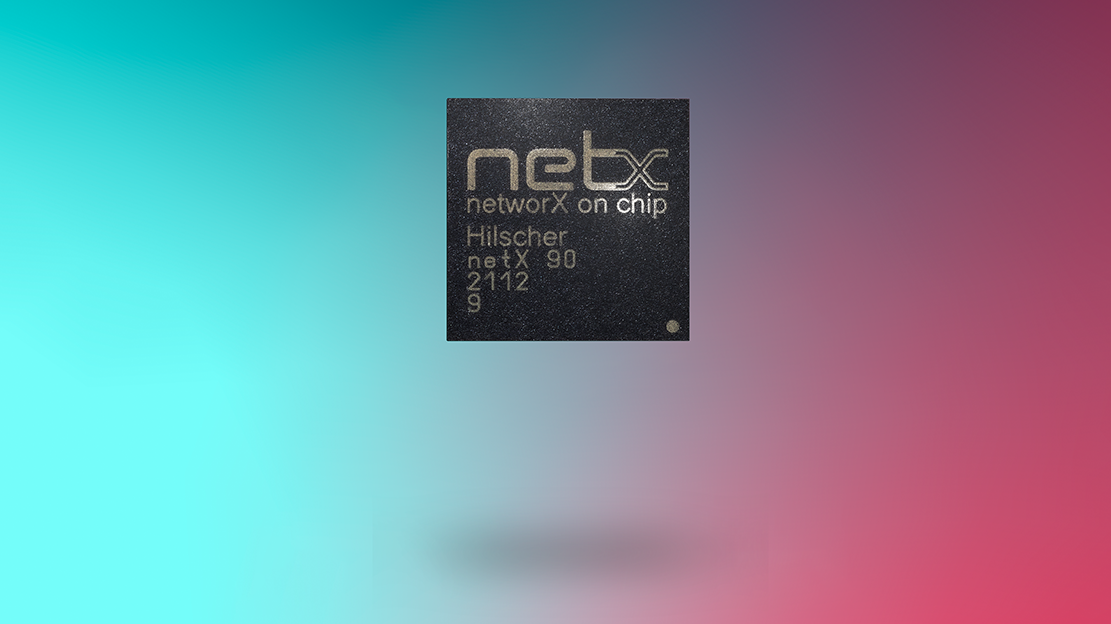

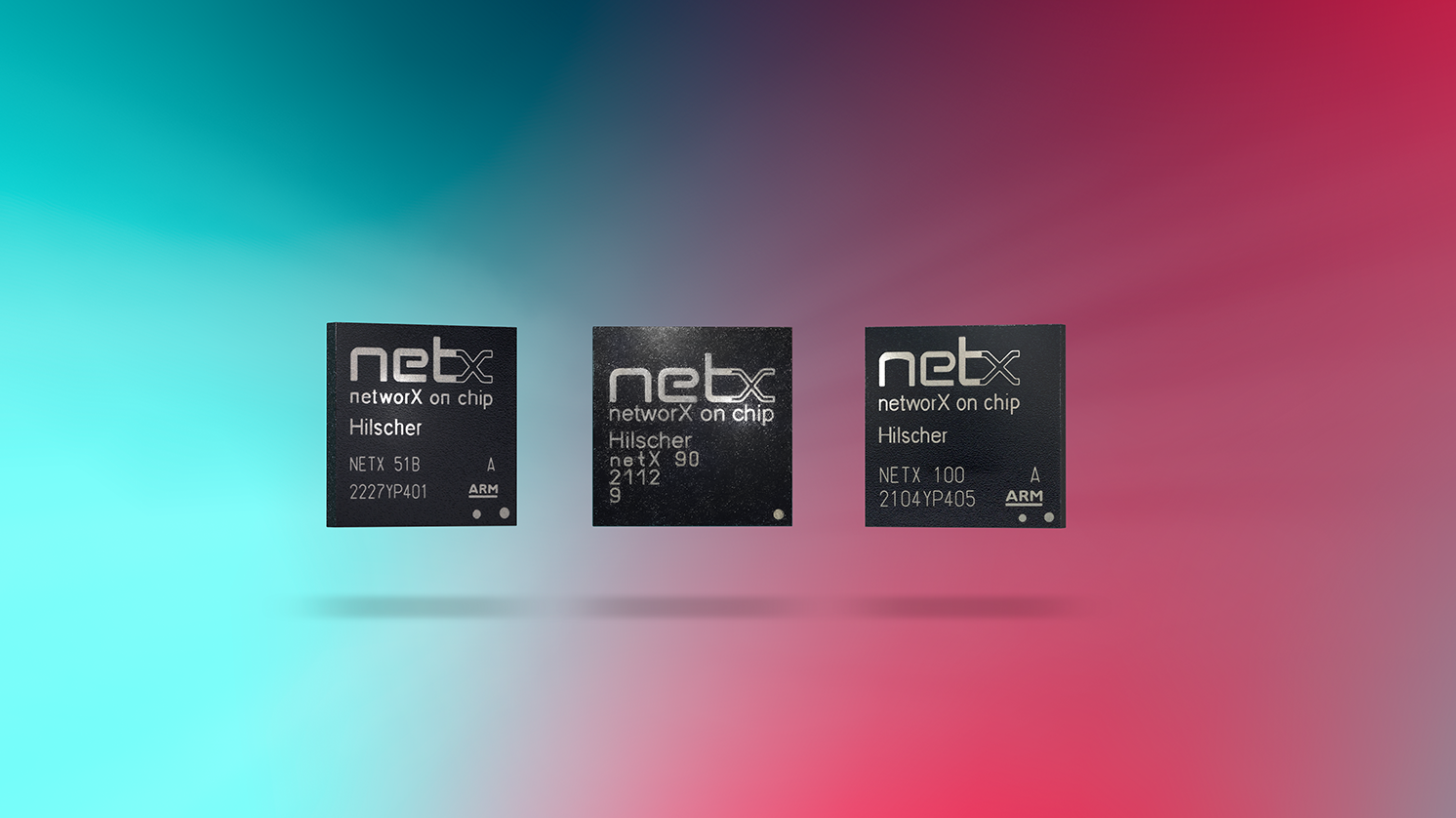

Compact, compatible, future-proof - these were the specifications for the development of the decentralized frequency inverter NORDAC ON. The company is expanding its product range with decentralized drive electronics that address the special requirements in horizontal conveyor technology - whether in typical warehouse applications of logistics service providers, intra-logistics in companies, or in regard to critical temperature ranges in demanding production environments such as the food industry. Also on board: the multi-protocol capable Hilscher network controller netX 90.

One design – Many protocols

„We have been working with Hilscher for several years and quickly took notice when the basic principle of the multiprotocol stack came up on Hilscher‘s agenda,“ says Frank Wiedemann, Managing Director of NORD Electronic Drivesystems.

The worldwide usability of a product and its compatibility with different controllers, is becoming increasingly important for many customers of the NORD DRIVESYSTEMS Group. The integration of a flexible Ethernet interface in order to support different industrial communication protocols such as EtherCAT, PROFINET or EtherNet/IP, while at the same time requiring fewer hardware variants, was naturally given a high priority for the new NORDAC ON frequency inverter series. With Hilscher’s netX 90 chip, such adaptions to different protocols are accomplished with a simple change of the parameter settings.