As automation becomes more and more complex, with demanding production processes and modularized machines, functional safety is becoming increasingly important. Compliance with relevant standards such as IEC 61508 or ISO 13849 as well ensuring adherence to legal requirements such as the European Union’s Machinery Directive 2006/42/EC requires secure communication between devices.

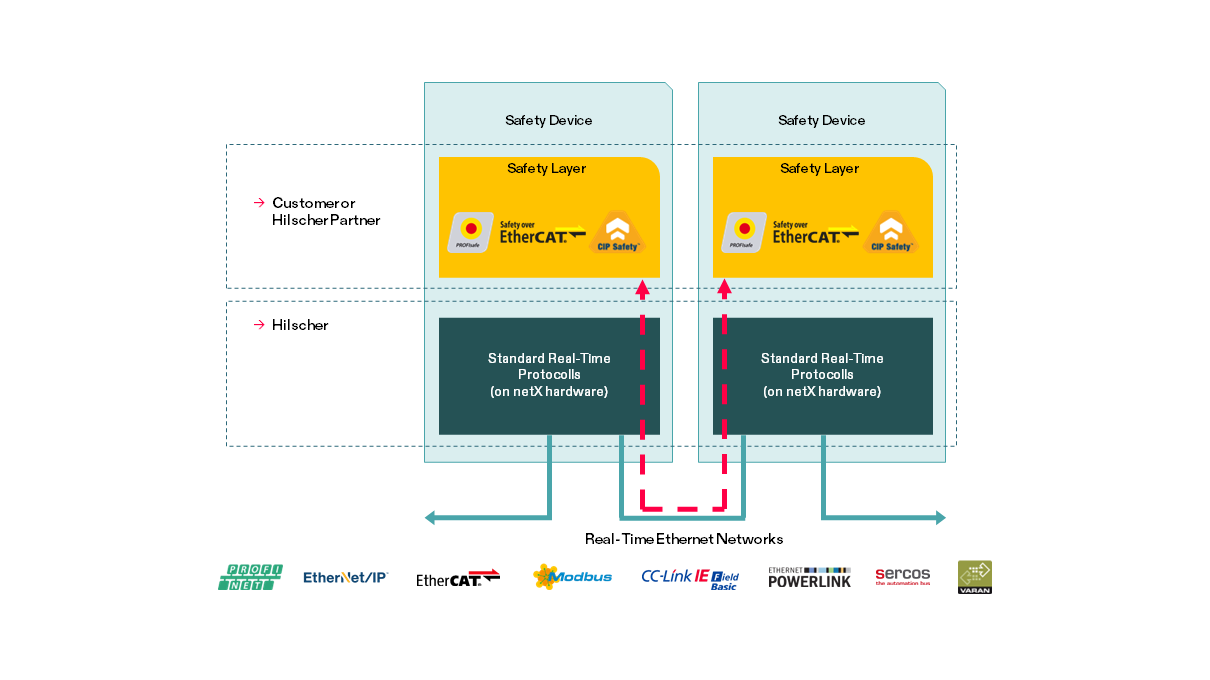

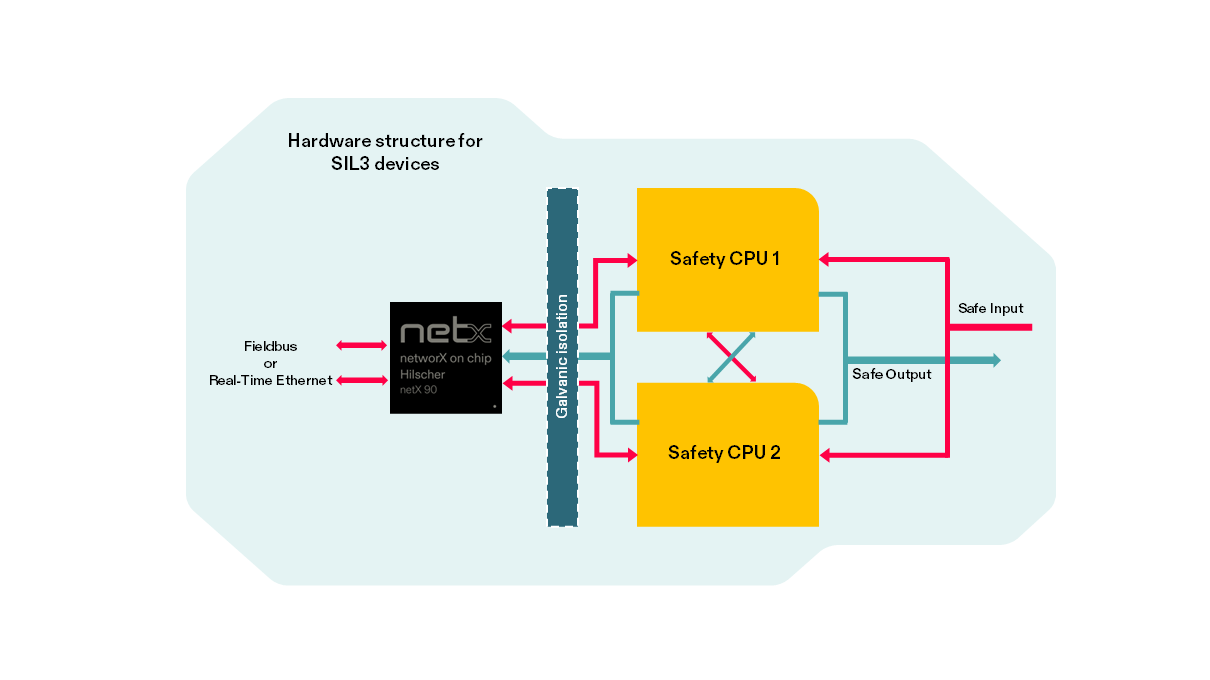

Hilscher’s netX communication solution is the perfect option to ensure compliance with all security-relevant standards, providing the perfect foundation for development of functionally safe systems up to Safety Integrity Level (SIL) 3.

- netX hardware provides the matching peripherals for connecting microcontroller architectures

- netX 90 hardware includes integrated monitoring and diagnostic functions

- The firmware supports Black Channel protocols

netX technology already serves as the backbone for secure industrial communication tasks in numerous machines and systems.