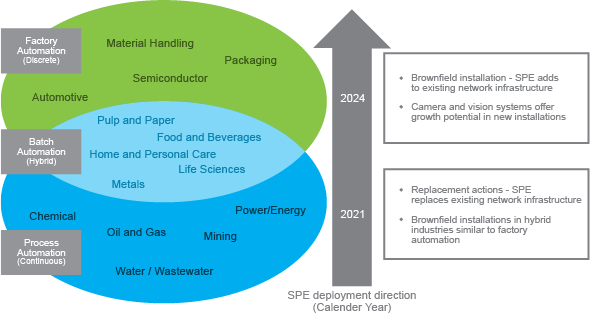

Hilscher expects an early adoption and deployment of SPE in the process automation sector starting around 2021. The reason is that the installations are based to a large extend on HART, PROFIBUS PA and similar fieldbuses that are not in the necessary extend supporting digital business models. The Namur Organisation and specially the FieldComm Group together with the PROFIBUS International (PI) and ODVA strongly drive the move to APL for process automation industries. The applications in these areas have usually lower performance and cycle time requirements and the deployment of diagnosis and parameterization through the network has not yet happened as much as in factory automation applications. On the other side, the deployment of SPE in factory automation might take a bit longer. Organization such as the ODVA, PI including the IO-Link group have started activities to evaluate the integration of SPE into their respective standards looking at positioning and the benefit in their applications. In parallel, there are two very active groups on their way to propose different plugs, connectors and cabling for the installation. Looking at all these very productive initiatives and the numerous open questions they address, a field deployment in factory automation would rather start around 2024.

As a conclusion we believe that those areas in the manufacturing industry, where equipment is still non-transparent to the upper layers in terms of status, diagnosis and parameterization, the overall system performance lacks and the advantages of digitization such as machine up time increase, availability, predictive maintenance etc. will not materialize. Therefore, the pressure in the process industry is expected to be much higher to act and move forward as quickly as possible.