Adding IoT value through passive PROFINET network data tapping

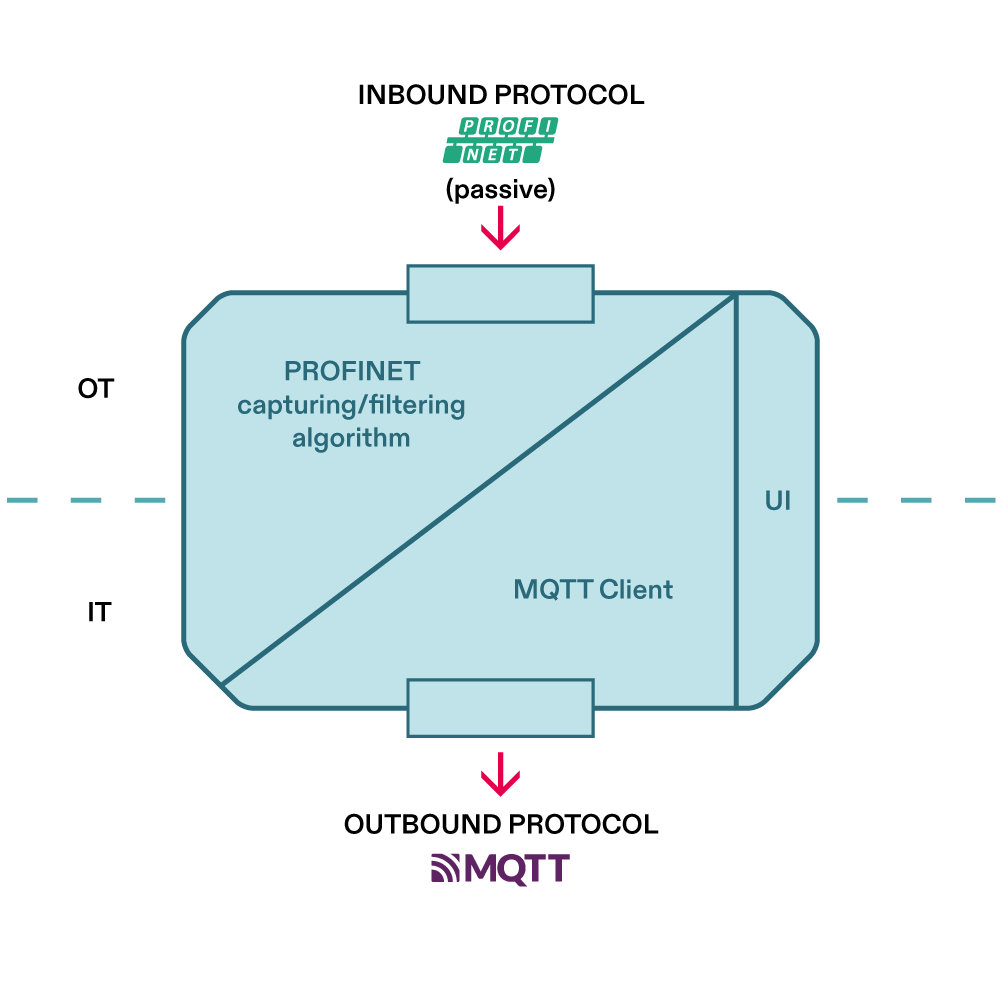

Hattersheim, 30. Mar. 2023 – Hilscher Gesellschaft für Systemautomation mbH is expanding its IoT portfolio with the containerized application netFIELD App PROFINET Tap. The application functions as a software gateway. It retrieves process data from a PROFINET network without relying on a PLC and converts the data into the MQTT protocol. By feeding the data into analysis software, plant operators can benefit from the data with minimal integration effort: For example, through early detection of anomalies in production processes or by optimizing processes after their analysis to increase productivity.

The container automatically identifies the PROFINET network topology during a network startup phase or prepares it topologically in its integrated web interface. Alternatively, the user can prepare the topology himself via the GSDML file. Users then individually define in the network tree which process data is to be published to an MQTT broker.

Technical Benefits - Compatible with any PROFINET controller

- Requires no changes in the PLC or machine configuration

- Has no influence on a running PROFINET network due to passive data capturing

- Can be easily integrated physically plug-and-play into any existing PROFINET system

- Is the fastest way to upgrade systems with modern IoT techniques by using popular MQTT as outbound protocol

- Works with a standard GBit Ethernet port as capturing interface

| Economical Benefits - Allows to derive measures to increase plants productivity after analyzing the PROFINET data

- Allows to study the overall behavior of controlled PROFINET signals through machine learning algorithms

- Enables gapless data capturing without data loss as precondition for reliable 24/7 data logging and evidence tracking

- Enables the realization of predictive maintenance scenarios due to long-term data mining

|

Still have questions? You might find these pages interesting!

Your download free of charge and more – visit our Knowledge Base!

Start your own IoT world with our turn-key app containers. Based on Docker technology, you can easily roll them out centrally and create new business opportunities!