Different protocol standards for Ethernet and fieldbuses, different modes of operation and data models, incompatible transmission mechanisms—industrial communication is exceedingly complex.

In the early 2000s, our founder, Hans-Jürgen Hilscher, thought it would be ideal if field device manufacturers would all use a single hardware platform that was compatible with all possible communication protocols. Based on this idea, the netX technology was born and became the standard for multiprotocol industrial communication. Since then, Hilscher has been coming up with solutions to reduce the complexity of developing and certifying your own devices. This allows you to cut your costs considerably for developing, warehousing and logistics.

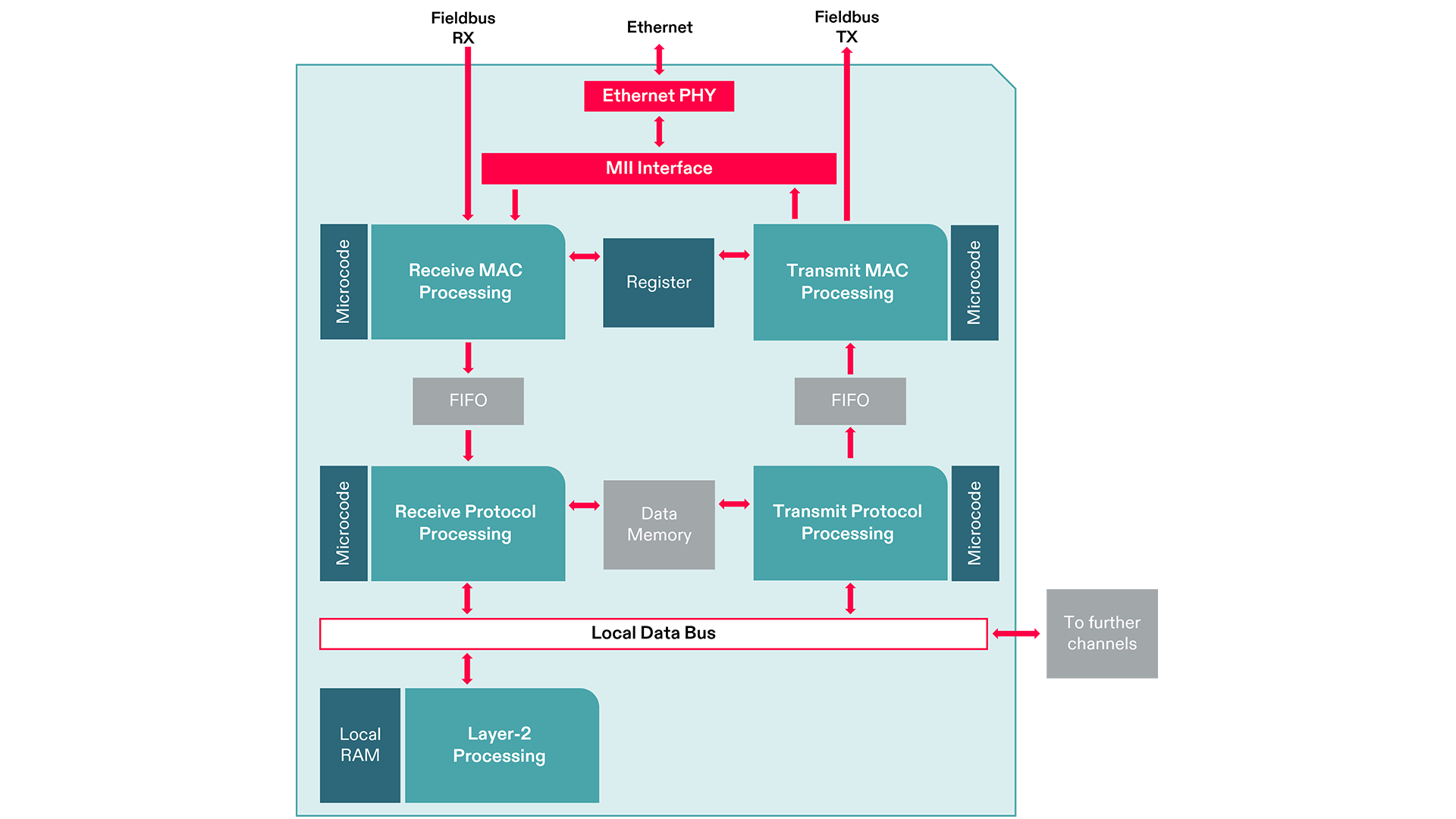

The netX technology is based on a patented programmable switch architecture consisting of Hilscher’s own interconnected CPU cluster. We supply the HAL drivers and firmware stack, which are used to adapt the netX platform to the applicable communication standard. This means that you can easily connect your field device to different controllers with a simple firmware change, without having to design and build new hardware.

Sounds easy? It is, and just as easy to deploy. Our engineers are also active members of all the relevant technology associations, so we’re always on the cutting edge when it comes to the latest standards. We integrate all the latest standards into our product portfolio so that you benefit from regular updates, keeping your machines up to date and at the cutting edge of technology

Multiprotocol communication in your product – our chips and modules for your highly integrated solutions.

Integrate machines and devices into your network – our turn-key communication solutions make it easy regardless of the network standard.

Centralized edge management made easy - your holistic IIoT platform for device and application management

The right communication solution for your industry – rely on Hilscher’s years of experience as the market leader in automation.

From legacy fieldbuses to Industrial Ethernet and the networking of modern sensors right up to the cloud – Hilscher’s industrial communication solutions in action.

Our IO-Link white-label products put the power of Hilscher’s communication capability in your own brand.

Our processors with variable protocol stacks make up our core technology. They are the foundation of many of our solutions. We also give you access to your machine data with our edge management solutions, paving the way to Industry 4.0.

Do you have any questions? Reach out to us or to one of our partners!

Under Downloads you’ll find numerous drivers, tools and manuals for our products.

We have been the market leader for industrial communications for over 35 years. 35 years in industrial applications and forward-looking research and development.

Find out what makes us who we are.

News, background information and a schedule of events where you can meet us – stay up to date on everything related to Hilscher and industrial communication.