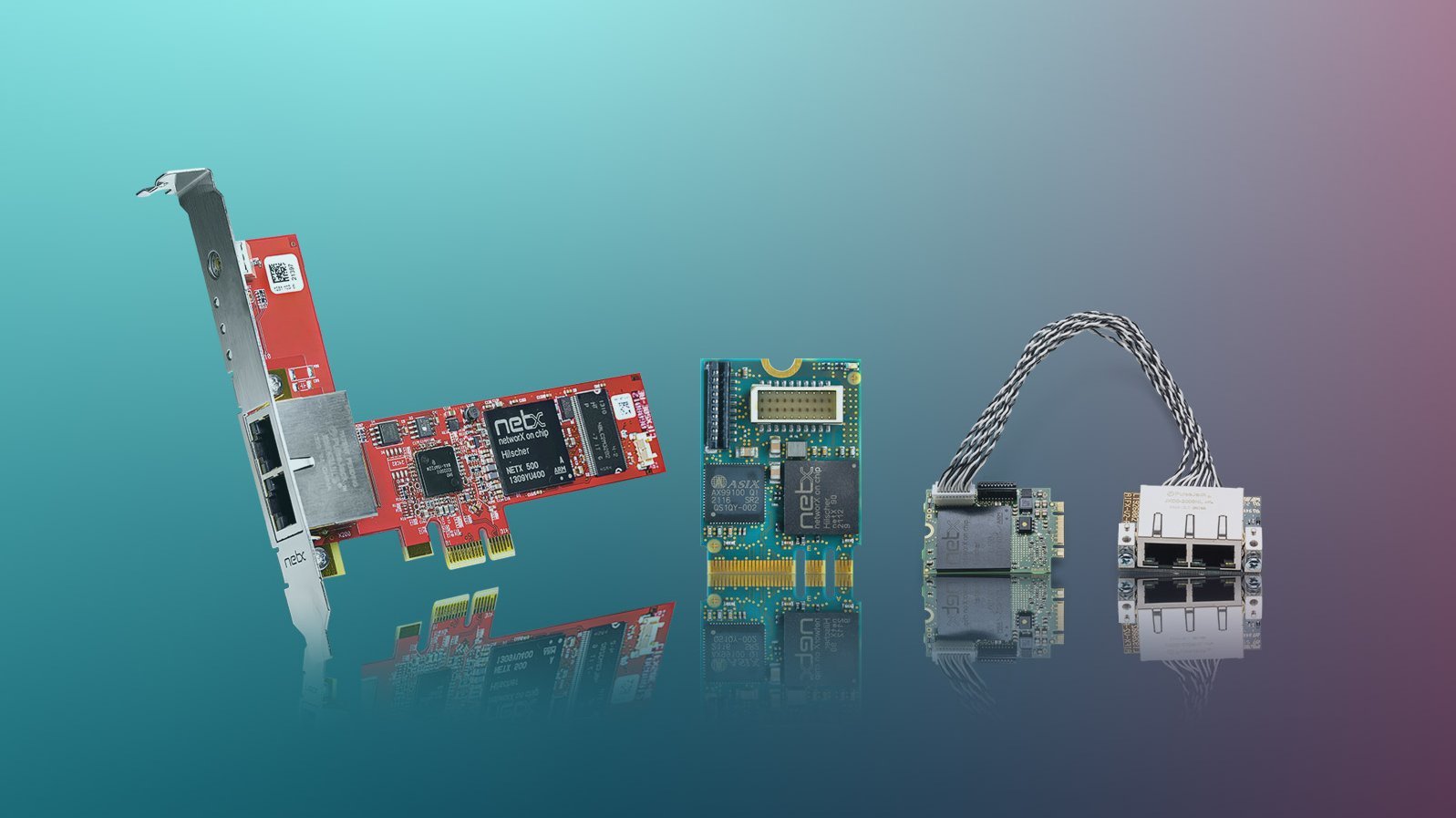

cifX PC Cards – All Formats and All Protocols

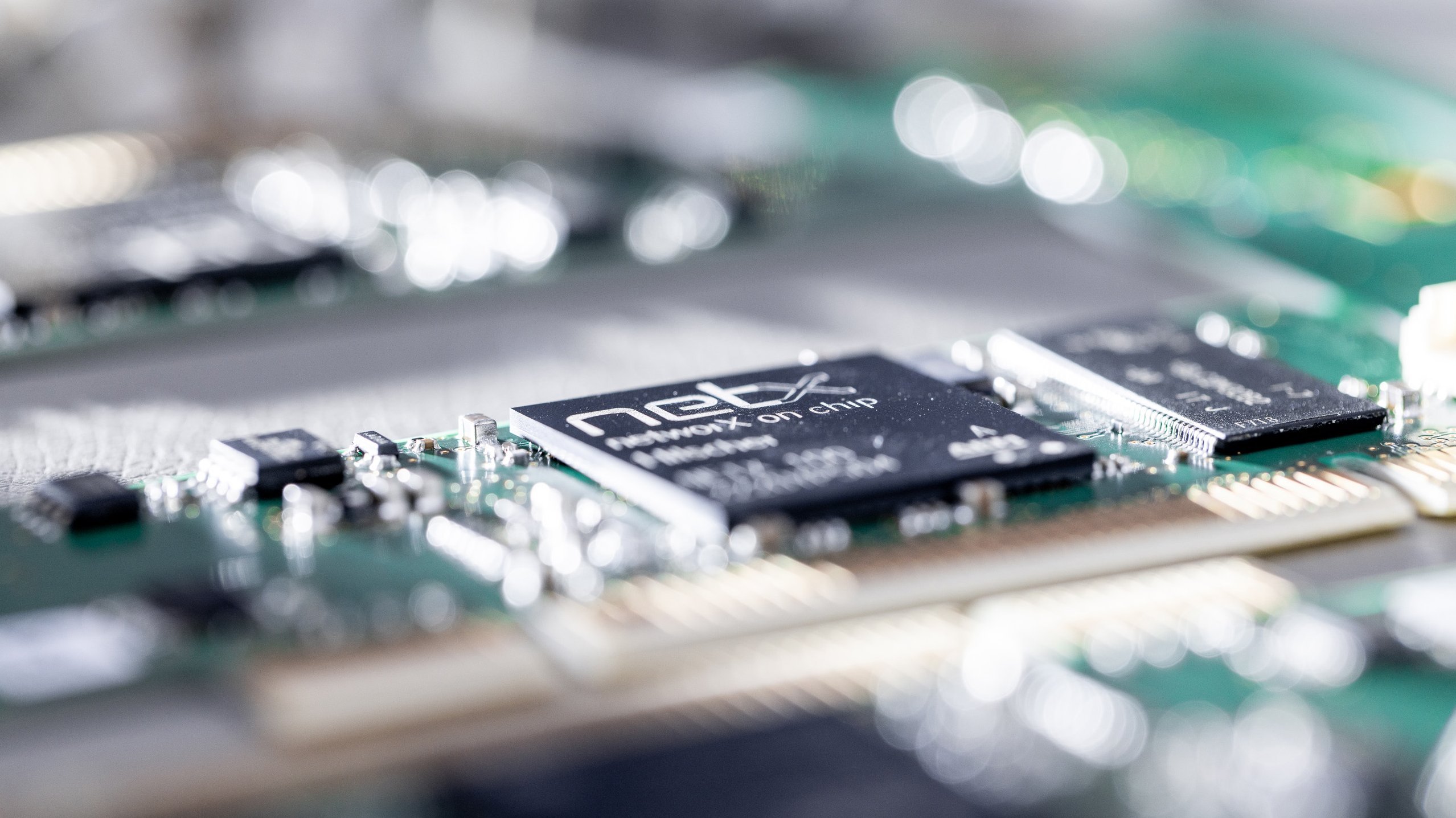

Hilscher‘s cifX PC cards are the easiest and fastest way to equip PC-based automation devices with a fieldbus or Real-Time Ethernet interface. The protocol stack is handled autonomously on the PC card using loadable firmware, and the data are exchanged with the host using dual-port memory or DMA (Direct Memory Access). Together with SoftPLCs, visualizations or own applications available on the market, they solve almost any automation task in the shortest possible time.

- Feasible for master and slave applications

- Ten card formats and 20 industrial master and slave protocols

- Standard drivers, tools and API for all cards thanks to Hilscher‘s platform strategy

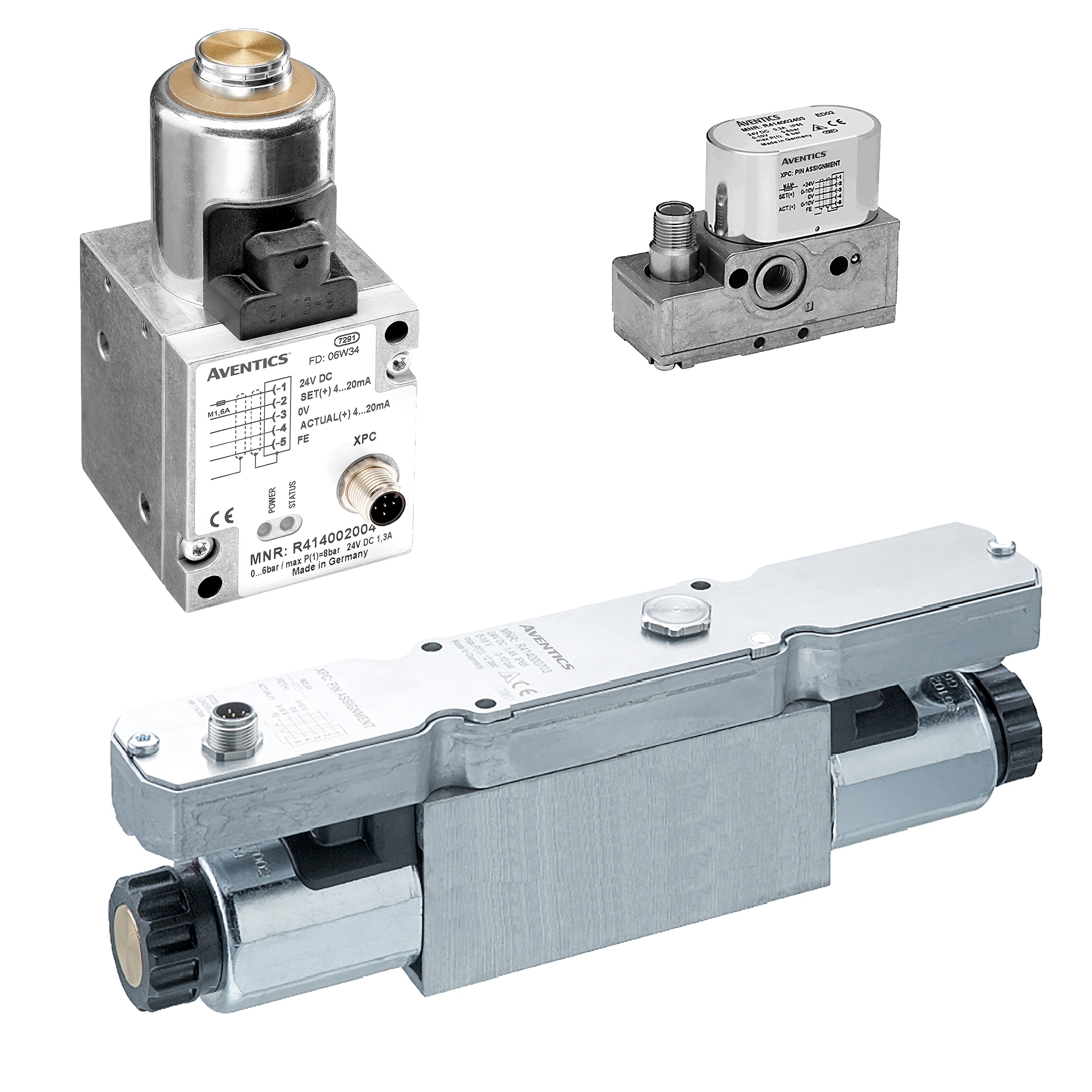

Holger Müller, Managing Director of müller+krahmer GmbH, outlines the application of AVENTICS GmbH in Laatzen, Lower Saxony, a well-known original equipment manufacturer and producer of pneumatic solutions and part of the Emerson Group: „In this case, we are realizing test benches for electro-pneumatic valves, known as ‘continuous valves’, which regulate pressures with high precision in proportion to the set value.“ These valves are all individually tested before they leave the factory. Part of the test process involves configuring the test specimens to take account of product and customer-specific pressure ranges, controller settings and interfaces, as well as comparing them with reference values, which are determined during the test. The configuration includes setting individual parameters as well as replacing the complete firmware and application software. The solution used by müller+krahmer must cater for more than 300 device variants. This means „a huge range of interfaces and a wide variety of designs and pressure ranges, some of which have been subject to quite extensive testing,” says Müller.