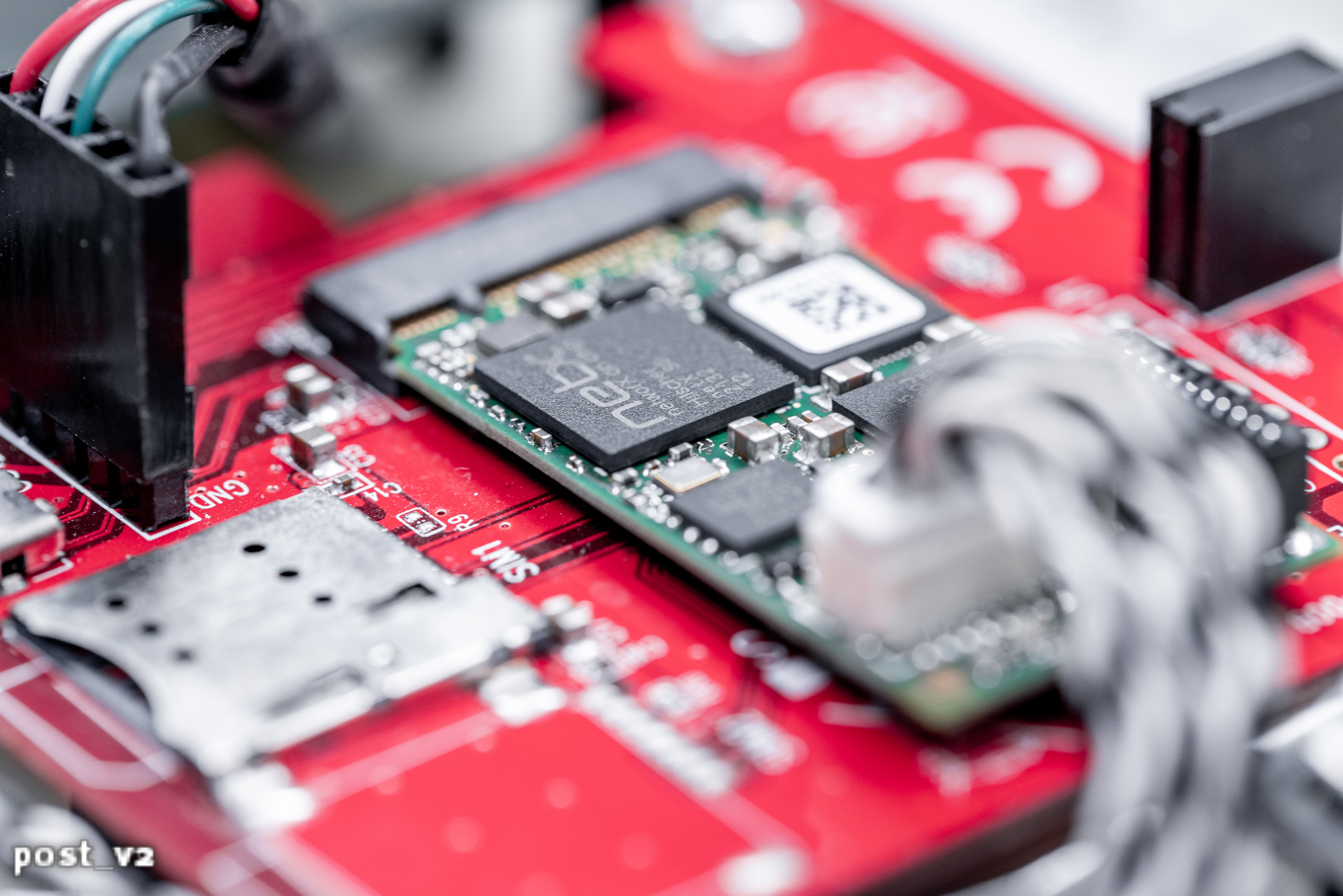

Thanks to our products, machines around the world are able to communicate with each other. Always included: our know-how and our netX communication controllers. The flexibility of netX technology is unique on the market, enabling reliable communication in countless production plants.

But it's our firmware that makes our chips what they are: a multi-protocol communication solution that takes your equipment's connectivity to the next level.

Our IoT ecosystem netFIELD is a direct application of these two technologies. With netFIELD, we make Industry 4.0 possible and bring your solutions to the cloud with our expertise.

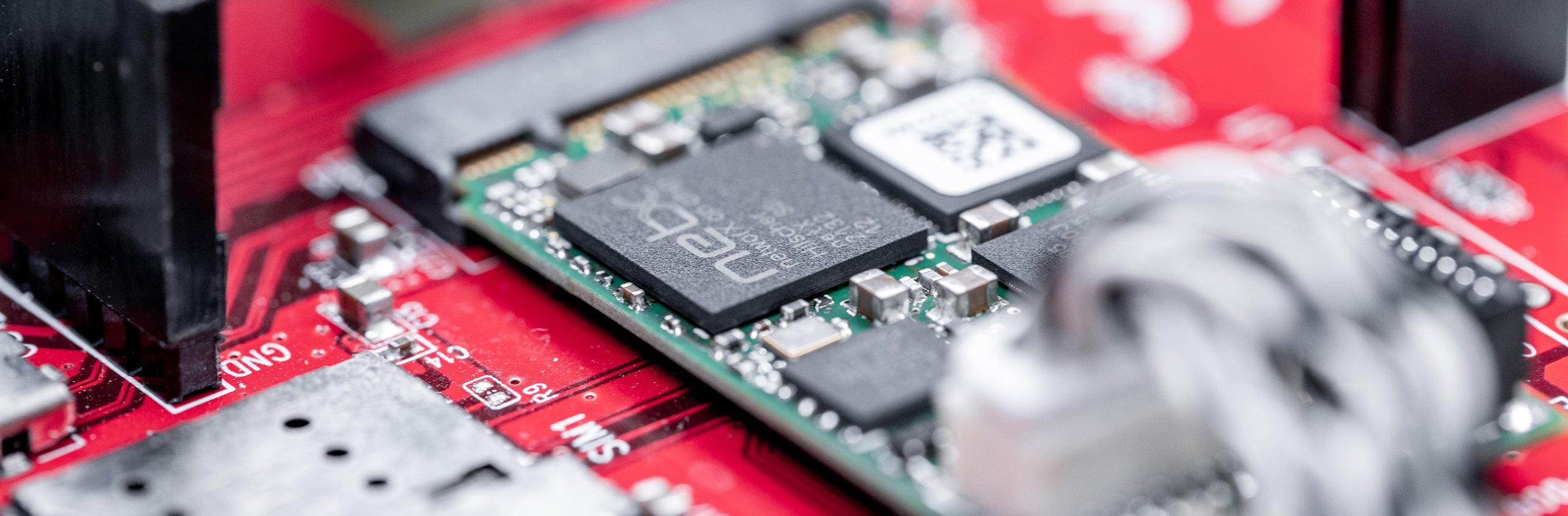

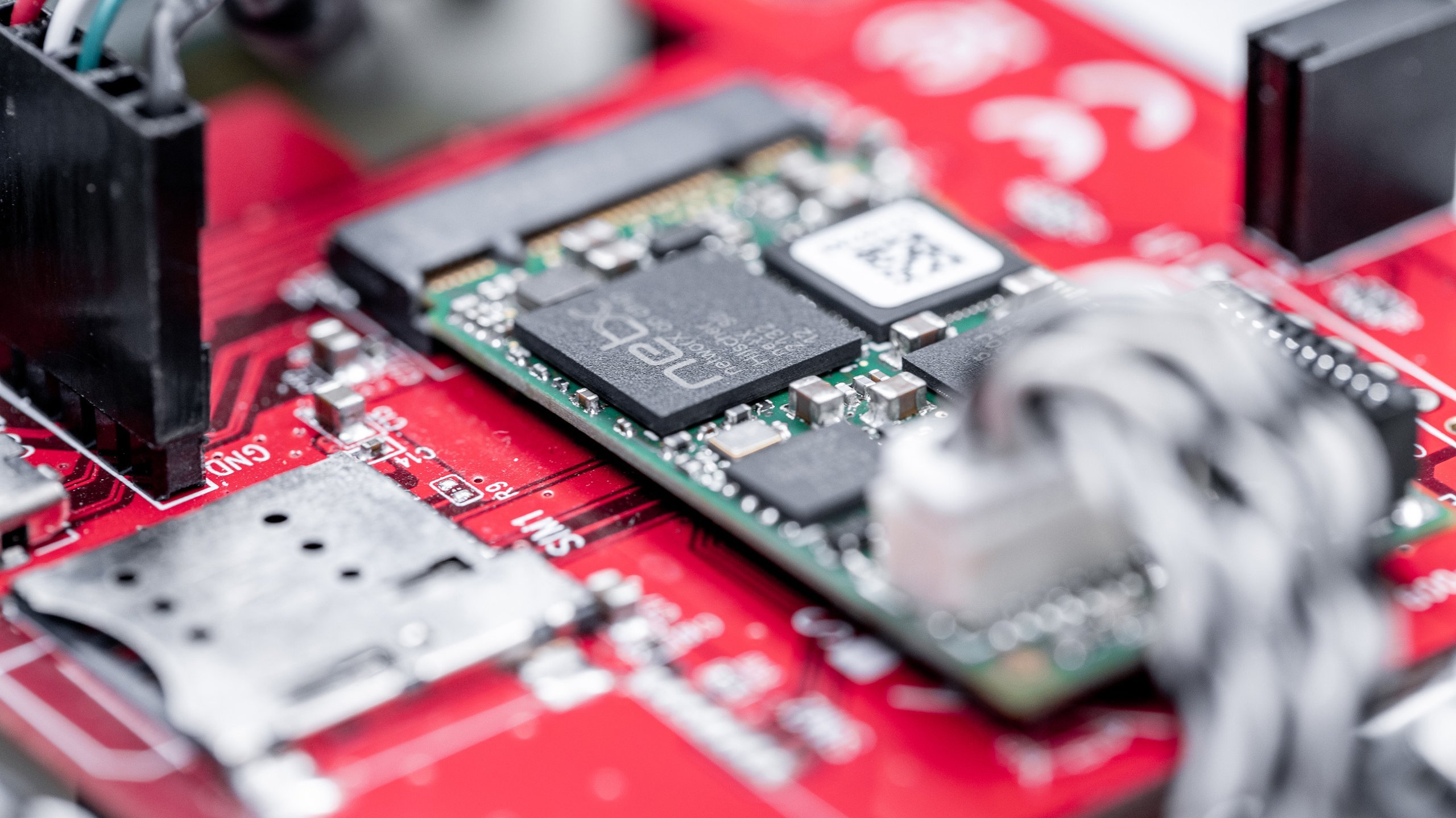

Multiprotocol communication in your product – our chips and modules for your highly integrated solutions.

Integrate machines and devices into your network – our turn-key communication solutions make it easy regardless of the network standard.

Centralized edge management made easy - your holistic IIoT platform for device and application management

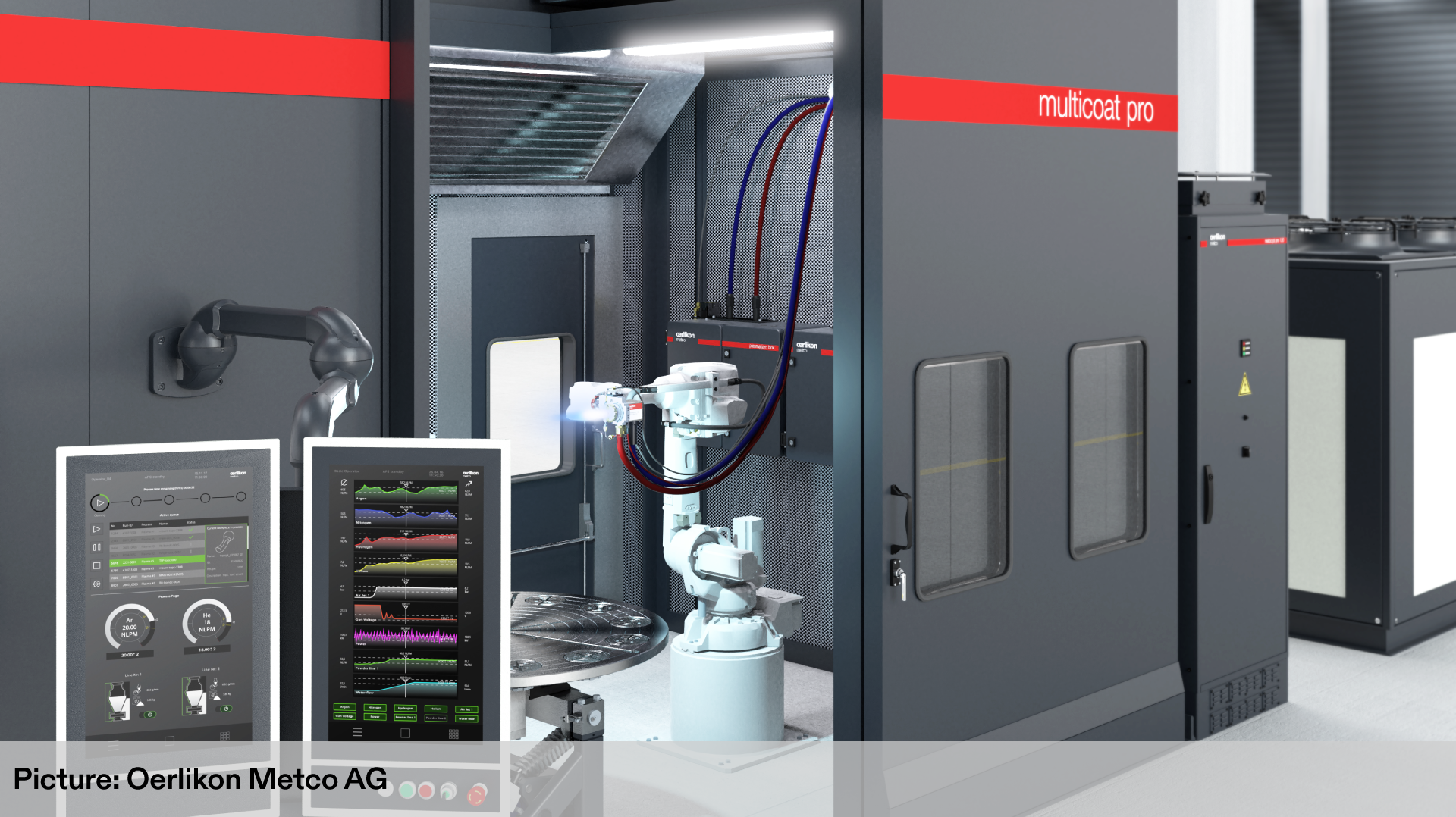

The right communication solution for your industry – rely on Hilscher’s years of experience as the market leader in automation.

From legacy fieldbuses to Industrial Ethernet and the networking of modern sensors right up to the cloud – Hilscher’s industrial communication solutions in action.

Our IO-Link white-label products put the power of Hilscher’s communication capability in your own brand.

Our processors with variable protocol stacks make up our core technology. They are the foundation of many of our solutions. We also give you access to your machine data with our edge management solutions, paving the way to Industry 4.0.

Do you have any questions? Reach out to us or to one of our partners!

Under Downloads you’ll find numerous drivers, tools and manuals for our products.

We have been the market leader for industrial communications for over 35 years. 35 years in industrial applications and forward-looking research and development.

Find out what makes us who we are.

News, background information and a schedule of events where you can meet us – stay up to date on everything related to Hilscher and industrial communication.