Controlling drives with netX

Today, modern drive technology is essential for your automation systems and the implementation of industry 4.0 standards. Irrespective of the application, drives in the automation network must interact with each other easily, flexibly and smoothly. That, however, requires high-performance interfaces for connecting to modern fieldbus or Real-Time Ethernet networks.

Modern drive applications tend to rely on decentralized compact controllers with centralized motion automation.

This type of setup places high demands on your communication components:

- Drives with real-time communication capabilities

- Compatibility with different motor types

- Smallest form factor for highly compact solutions

- Easy integration

netMOTION – compact drive technology meets real-time communication from the market leader.

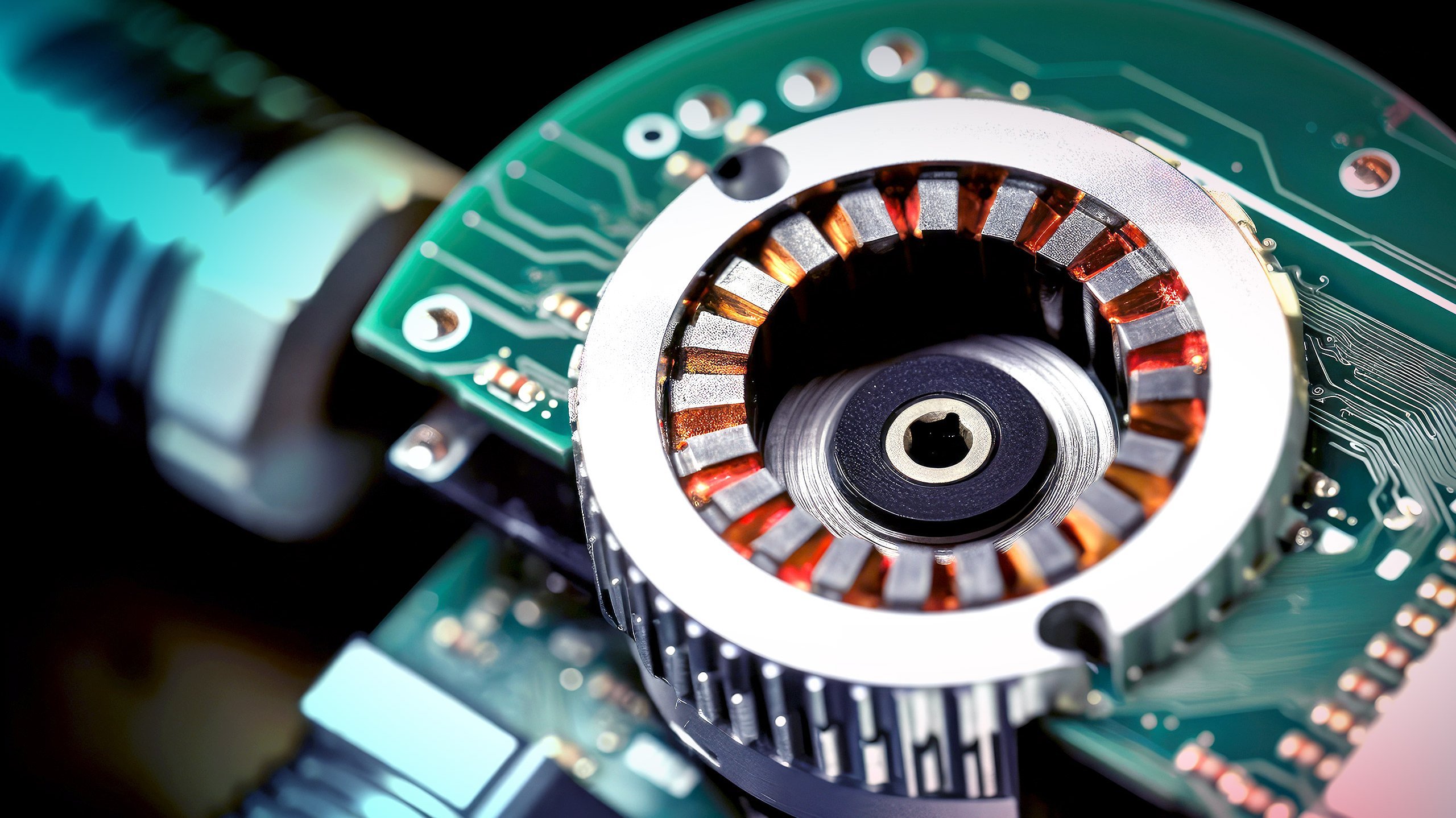

netMOTION provides firmware-configured real-time communication with integrated motor control for 3-phase BLDC or PMSM motors.

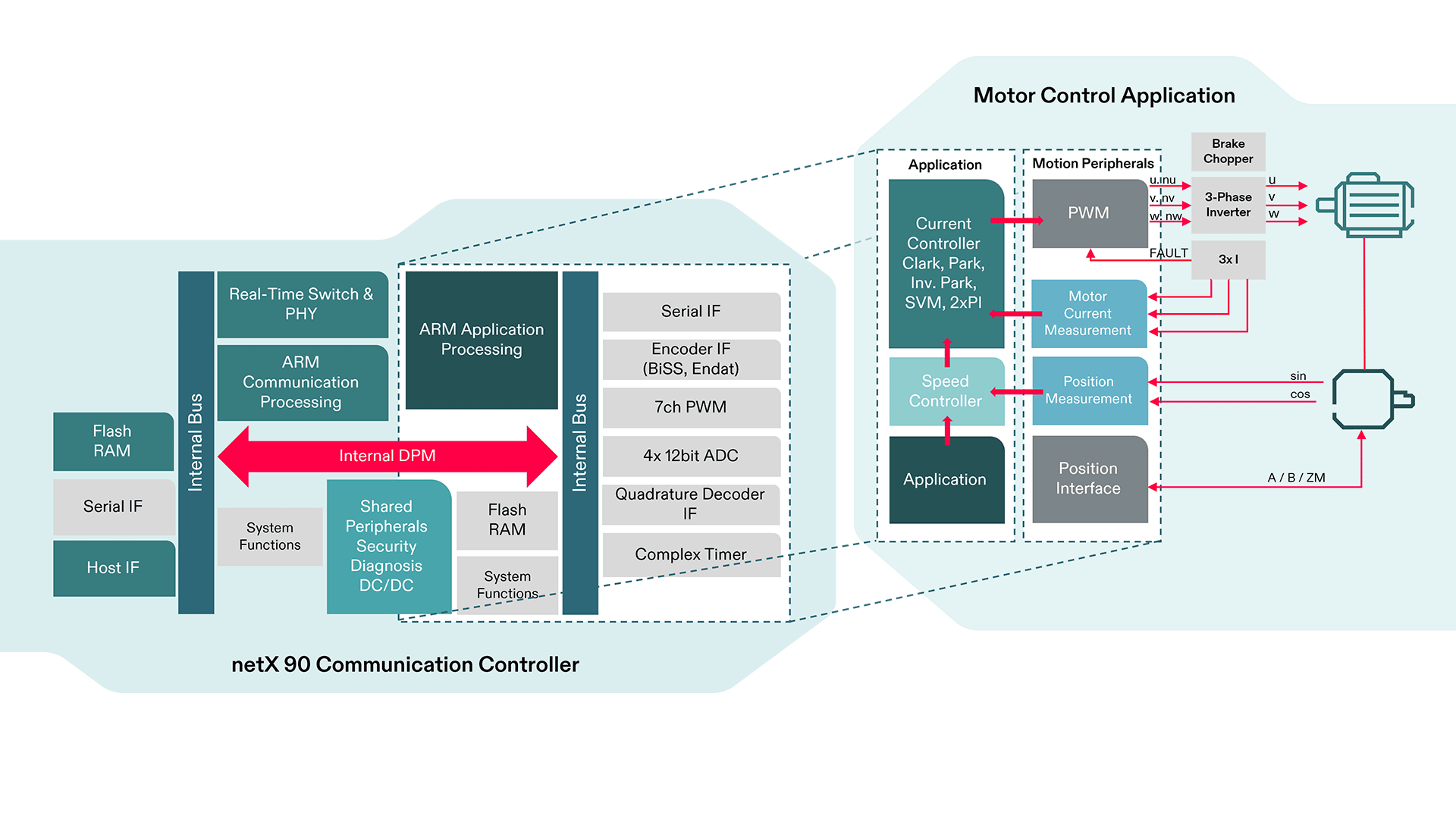

Based on Hilscher’ netX 90 multiprotocol network controller, this communication solution for compact drives uses the integrated 100 MHz application CPU to control drives. The netX 90 is also equipped with additional on-chip peripherals for motion control applications:

- 7-channel PWM with external trigger and brake chopper

- Complex timer with dead-time compensation and extensive trigger functions

- Four high-precision 12-bit AD converters with a conversion time of 2 µs

- Several analog and digital encoder interfaces

The position feedback is based on Hall sensors or encoder signals. For the communication side of things, netMOTION is equipped with our proven netX platform. This gives you deterministic and network-synchronous control of your drives with solutions from the industrial communication experts!

Delivering accuracy and precision where space is limited is the challenge. With netX 90 and netMOTION, you can easily meet this challenge and flexibly connect your drive to all network standards.

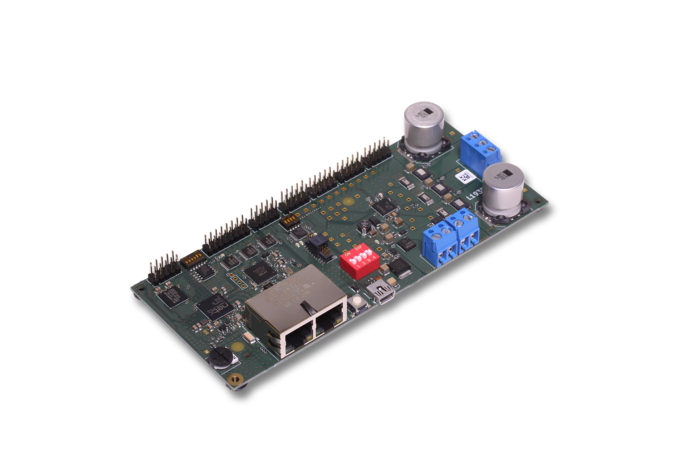

Compact drives are controlled directly in robot applications as well as in autonomous transportation systems such as automated guided vehicles (AGVs). This is where a space-saving and efficient system is of critical importance. With netMOTION, you can use a single chip for drive control and communication.

Easily control and connect drive systems with long run times or extended temperature ranges with Hilscher and netMOTION.

Your advantages with netMOTION

Compact design

Communication and drive control in a single chip

Save on development costs

Motion control and communication development in a single chip environment

Perfect synchronization

Optimum synchronization between the motion and communication ends ensured by the internal DPM architecture

Motion-Know-How

Complete Field Oriented Control (FOC), math library, hall sensor connection and much more in our netX Studio development environment

Smallest multiprotocol SoC