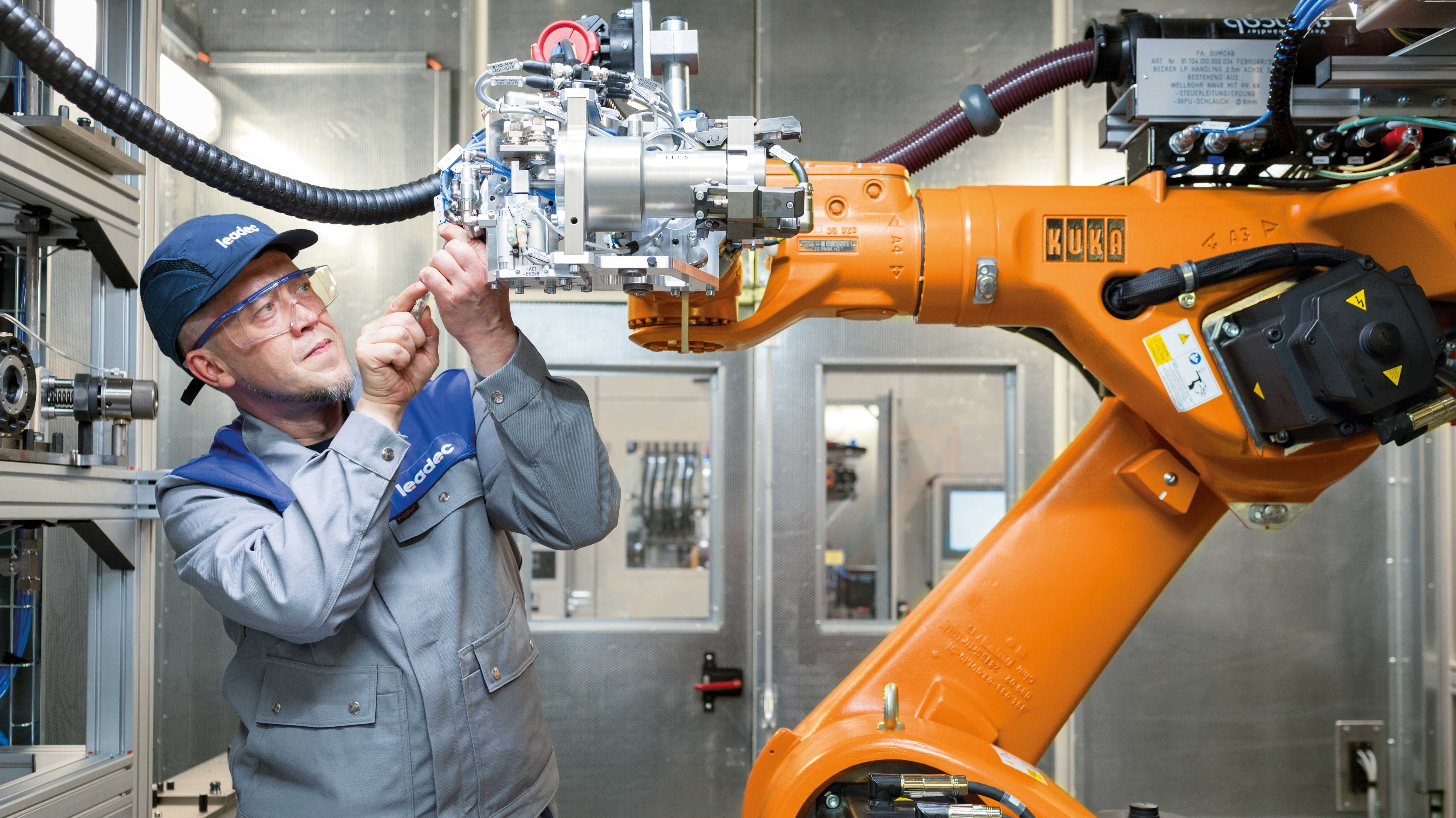

Leadec is the leading service specialist for factories along their entire life cycle. Headquartered in Stuttgart, the global company plans, installs and maintains technical systems of all kinds, ensuring perfectly functioning production lines around the globe.

Leadec has special expertise in troubleshooting anomalies in Real-Time Ethernet networks. The service provider systematically supports system integrators and production plant operators in detecting faults. Leadec saves companies millions in unnecessary additional costs. But localizing faults is usually a very complex procedure.

Reliability as an elementary attribute

Modern production facilities are made up of a large number of networked machines and components that communicate and collaborate with each other in real time. Any one system is very rarely anything like another. Even the smallest deviations or disruptions in the automated processes can have profound effects. For this level of complexity the analysis specialist relies on Hilscher’s netANALYZER technology for troubleshooting.

For Leadec, the reliability of its measuring tools is the most important factor in ensuring that they’re not led down the wrong path while detecting anomalies. Being misled can cost days or even weeks, leading to considerable financial loss. Considering what’s at stake, the service specialist examined over 20 of the most common analysis tools on the market to see if they work without impacting the monitored system. The result: Hilscher’s netANALYZER is one of only four devices that do not have telegram losses, short circuits or similar issues.