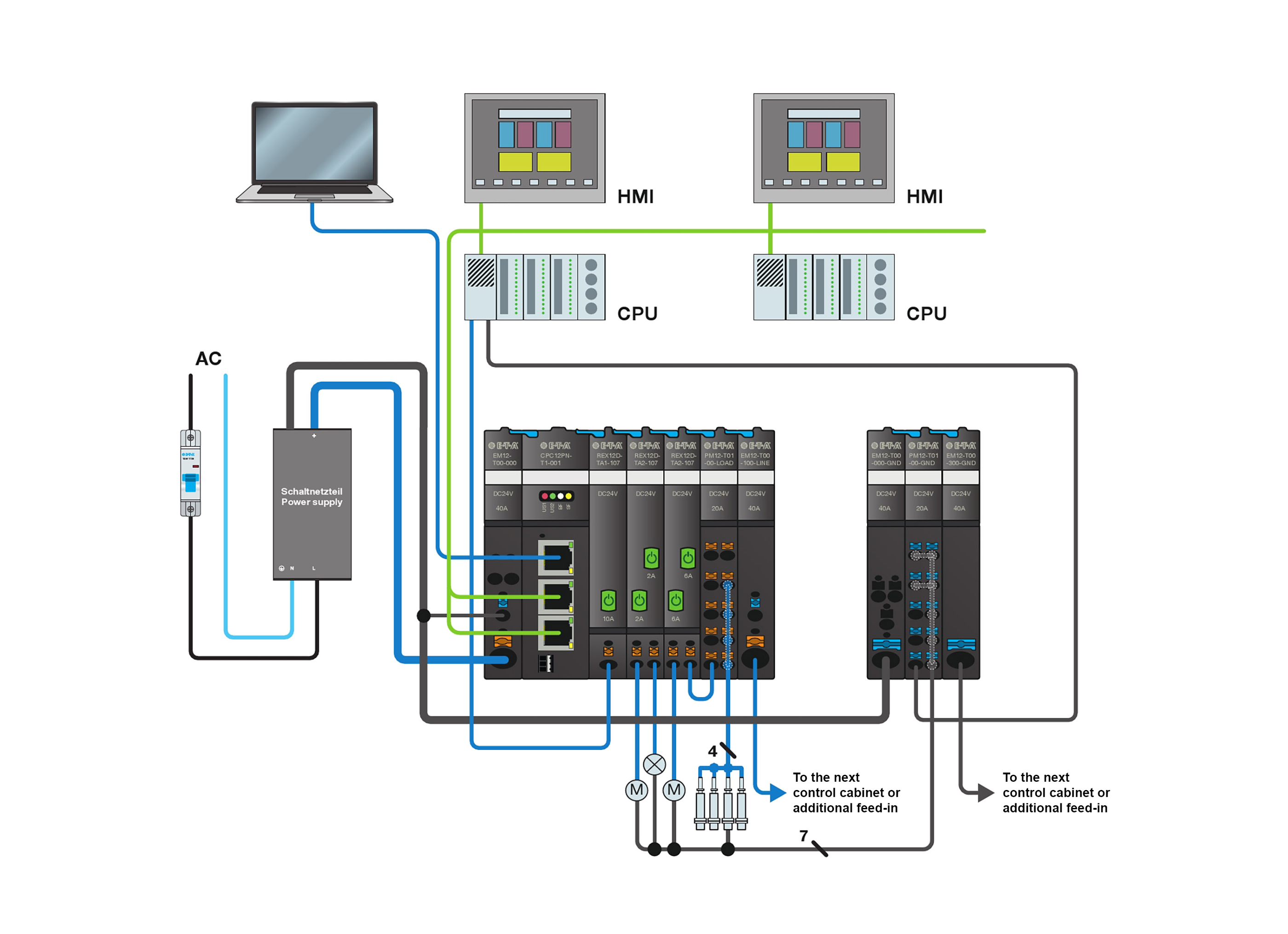

E-T-A Elektrotechnische Apparate GmbH from Altdorf in central Franconia is the world market leader for circuit breakers and overcurrent protection. The medium-sized company operates globally in the sectors of mobility and transportation, industry and production, telecommunications as well as medical and device technology. At a customer’s request, E-T-A decided in 2019 to develop an inexpensive bus controller for the electrical circuit breakers of the REX12D series. The controller is designed for use in machines in automated environments, in general, and for lathes with multiple sensors and drives, in particular. The fieldbus connection is used for continuous data transfer of all status information and measured values of the overcurrent protection system. Reliable detection of overloads and short-circuits provides effective protection against unwanted anomalies and plant downtimes and their negative impact.

For the design and development of the fieldbus connection, E-T-A Systemtechnik consulted LEBER GmbH & Co. KG for advice. The service provider from Schwaig near Nuremberg has extensive experience in integrating communication functionality into a wide range of systems and products. LEBER’s task was to create a multiprotocol capable device including circuit diagram, BOM, layout, EMC and ESD testing. This involved implementing and certifying the protocol stacks relevant for E-T-A for PROFINET, Modbus, EtherCAT and Ethernet/IP.

As a result of the cooperation, the ControlPlex System CPC12 was created, which provides transparency across all levels of the automation pyramid thanks to Hilscher’s netX 90 communication controller. Three major factors led to the decision to use Hilscher technology: speed of development, form factor and pricing.