Die Zukunft der Halbleiterindustrie

Die Zukunftsaussichten für die Halbleiterindustrie sind mit einem prognostizierten Wachstum von ca. 9% in 2022 durchaus positiv. Jedoch kommt es, unter anderem durch die Auswirkungen der anhaltenden Corona-Pandemie, in der Branche immer wieder zu Lieferengpässen. Durch die Entwicklung eines neuartigen Kommunikationsmoduls speziell für die Halbleiterindustrie unterstützt Hilscher diese nun bei der Bewältigung der aktuellen Situation.

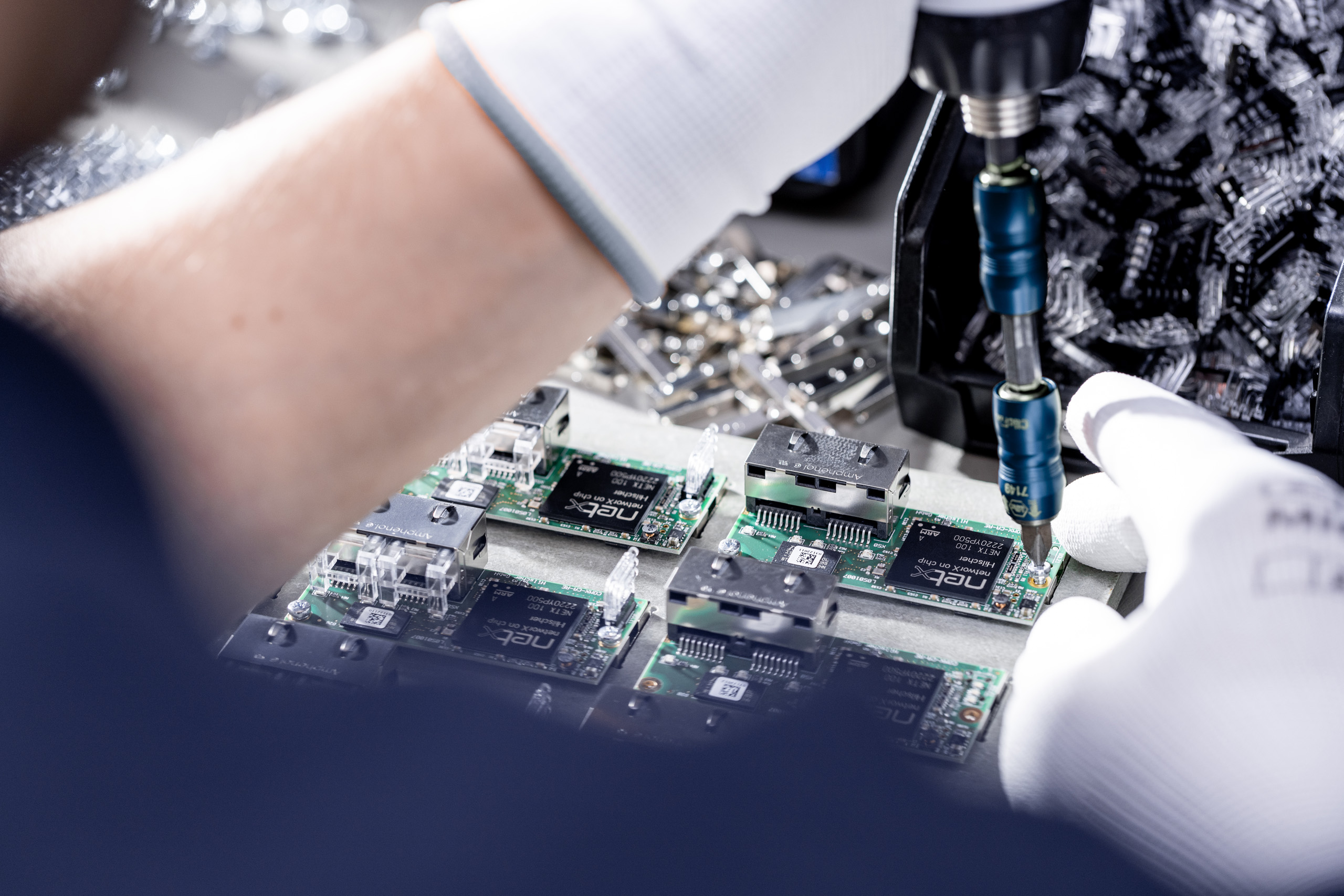

25 Jahre Embedded Module von Hilscher

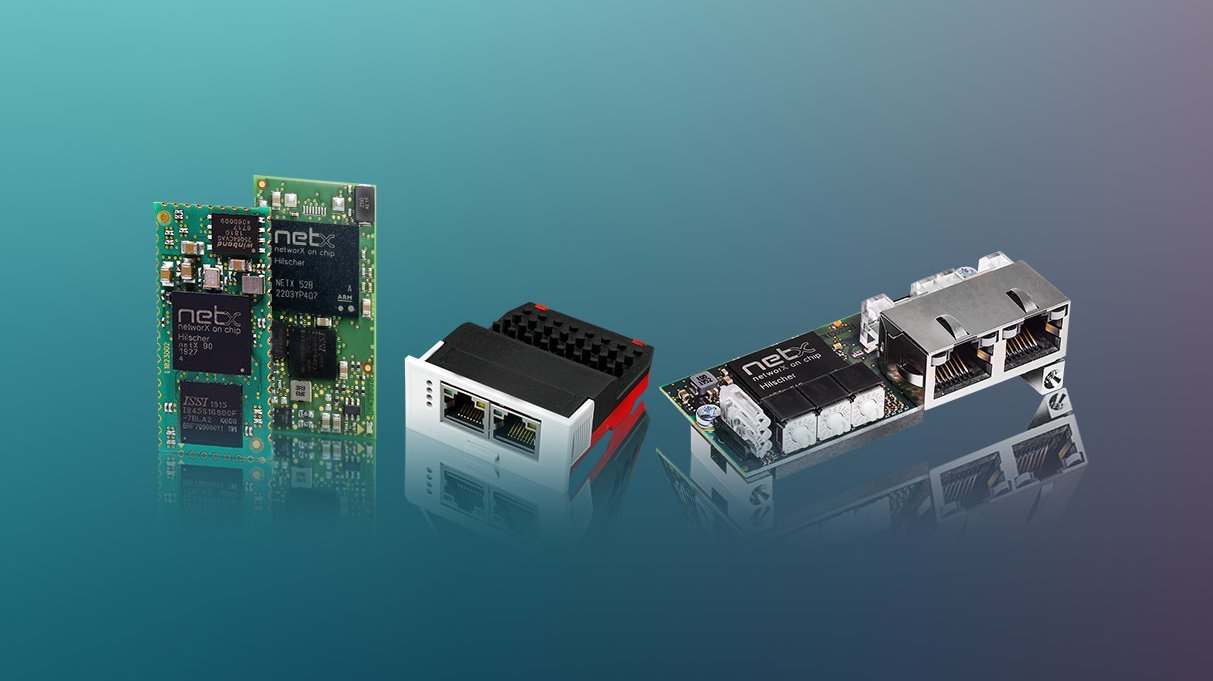

Kommunikationsmodule von Hilscher werden seit über 25 Jahren in der industriellen Automation bei einer Vielzahl erfolgreicher Unternehmen eingesetzt. Ihre Fähigkeit alle führenden Real-Time-Ethernet Protokolle als Master oder Slave in exakt einem Design zu unterstützen findet bei Herstellern von Automatisierungsgeräten wie z.B. Robotersteuerungen, SPSen oder Antrieben enormen Einklang.

Hilschers „comX“ Standard basiert auf einer durchdachten Plattformstrategie. Alle comX Module haben die gleichen Abmessungen und sind pin-kompatibel. Somit kann der Anwender mit lediglich einem Grundplatinendesign das komplette Spektrum aller Industrieprotokolle abdecken. Dank einheitlicher Schnittstellen kann schnell und flexibel auf neue Marktanforderungen reagiert werden – und das mit maximaler Zeit- und Kostenersparnis.