Anlagen- und Maschinenbau

Die zunehmende Vernetzung von Maschinen und Anlagen und deren Komponenten eröffnet umfassende Potenziale für das Überwachen industrieller Prozesse. Mit intelligenten Kommunikations- und IIoT-Lösungen ziehen Sie Vorteile und Potenziale aus bisher ungenutzten zusätzlichen Daten. Die konsolidierte Zusammenführung und Analyse der Informationen offenbaren Ihnen viele ungeahnte Erkenntnisse zur Schaffung neuer Geschäftsmodelle. Aufbauend auf unserer jahrelangen und marktführenden Expertise verfügen wir über ein breites Portfolio industrieller Kommunikationslösungen. Damit unterstützen wir Sie ganzheitlich bei der Aggregation, Orchestrierung und Nutzung Ihrer Daten – ob in Neu- oder Bestandsanlagen. Von IO-Link-Lösungen über multiprotokollfähige Netzwerkschnittstellen und intelligente Edge Devices bis Remote Management und Netzwerkanalyse-Tools haben wir für jede Ihrer Maschinen und Anlagen die passenden Lösungen parat.

Herausforderungen für Maschinen- und Anlagenbauer

Flexibilität und Variabilität

Ihre IPCs und HMIs müssen viele Protokolle über verschiedene Märkte und Regionen hinweg unterstützen. Mit unseren Multiprotokoll-Lösungen machen Sie daraus für sich einen Wettbewerbsvorteil. Reagieren Sie flexibel auf Kundenwünsche – mit nur einer Hardware unterstützen Ihre Systeme jedes Protokoll.

Brownfield-Systeme

Bestehende Anlagen rückwirkungsfrei um IoT-Funktionalitäten ergänzen: Mit unseren Edge-IO-Link-Master-Lösungen gelingt das im Handumdrehen. Datenfilterung und Protokoll-Mitschnitte liefern Ihnen unsere Netzwerk-Analyselösungen.

Remote Management

Als Maschinenbauer vertreiben Sie Ihre Produkte oft weltweit. Doch manuelle Überwachung und Verwaltung der Systeme vor Ort ist teuer und nicht mehr zeitgemäß. Unser netFIELD-Ökosystem bietet Ihnen ein breites Lösungs-Portfolio, um Ihre IoT-Projekte zentral zu überwachen und zu verwalten.

Als Kommunikationsspezialisten haben wir es uns bei Hilscher zur Aufgabe gemacht, Anlagen- und Maschinenbauer mit innovativen Lösungen zu unterstützen. So können Sie sich auf Ihre Kernkompetenzen fokussieren und bei den Themen Kommunikation und Konnektivität auf unser führendes Know-how aus über 35 Jahren Erfahrung mit industrieller Kommunikation vertrauen. Von klassischen Gateways zur Protokollkonvertierung bis zu kombinierten Edge- und Cloud-Lösungen bietet unser Portfolio alles, um Ihre Systeme für moderne Industrie-4.0-Infrastrukturen vorzubereiten. Auch Bestandsanlagen binden Sie mit unseren Lösungen unkompliziert in Feldbus-, Real-Time-Ethernet- oder Industrie-4.0-Umgebungen ein. Gemeinsam mit Ihnen setzen wir jeden Anwendungsfall um. So vertrauen bereits eine Vielzahl an Maschinen- und Anlagenbauer unterschiedlichster Branchen auf unsere Kommunikationslösungen, z. B. aus den Bereichen industrielle Bildverarbeitung, Geräte- und Systemtests, Verpackung, F&B, der Instandhaltung oder auch der Prozessautomation.

Orange Precision Measurement implements PROFINET, EtherCAT, and EtherNet/IP as well as DeviceNet using Hilscher's netX 90 multiprotocol communication controller, enabling the American manufacturer of precision measurement tools to supply its products to various customers.

Der Flagship Store von Hilscher für die Open Industry 4.0 Alliance (OI4) Community zeigt die Einfachheit von App Stores in der Industrie. Anwender können damit Apps und Lösungen für die Automatisierung nutzen – geschützt und lizensiert mit CodeMeter von Wibu-Systems.

Oerlikon Metco AG, ein führender Anbieter von Oberflächenlösungen, setzt netFIELD ein, um die Echtzeit-Datenerfassung von Industriemaschinen wie thermischen Spritzanlagen weltweit zu ermöglichen.

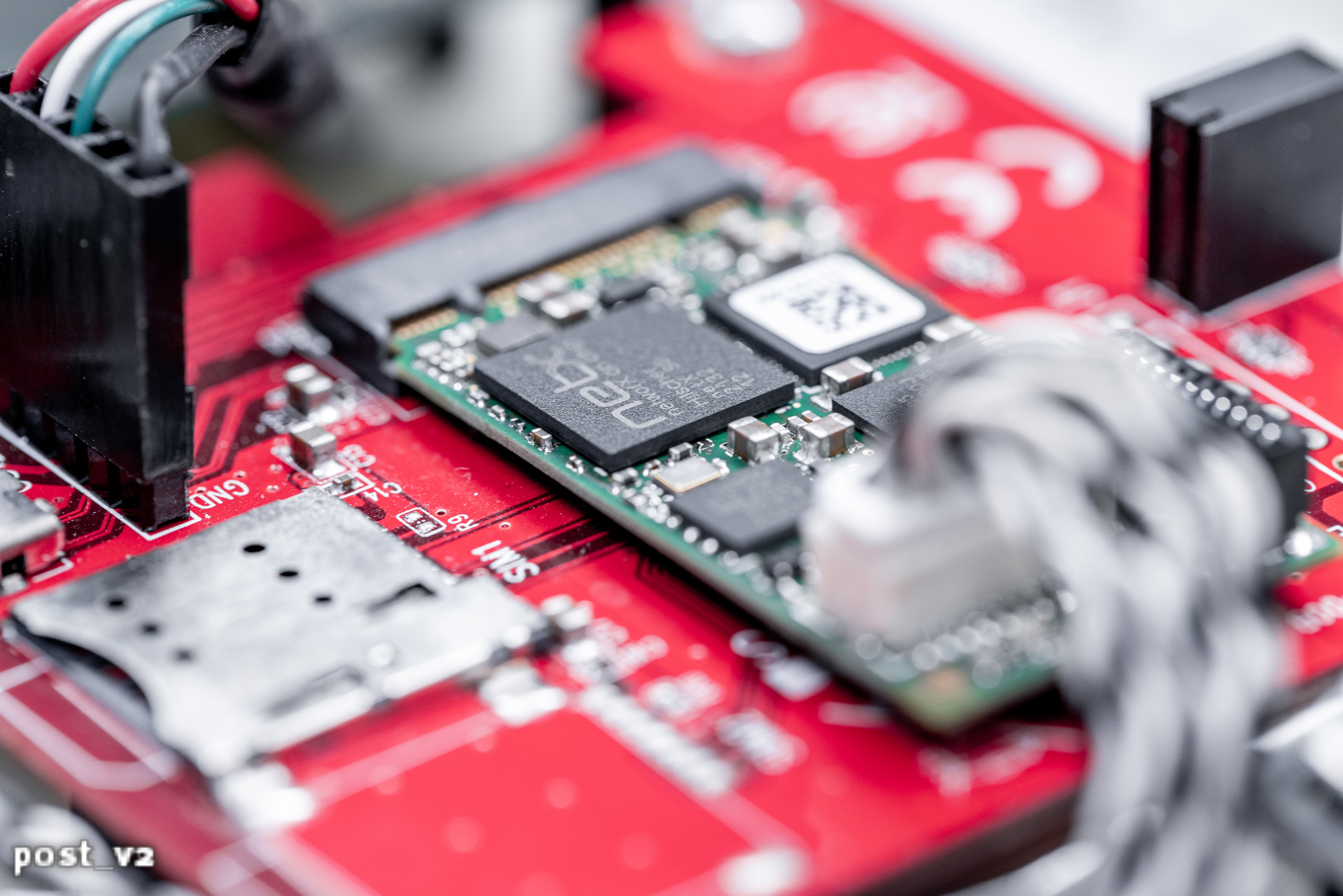

Vom Motorcontroller bis zur Konsolidierung gesamter Schaltschrankinhalte realisieren dieEntwickler Elektronik (dEE) innovative netX-90-Projekte und erschließen die gesamte interne Peripherie des kleinen Multiprotokollcontrollers.

Mit den Embedded-Modulen netIC 52 und netRAPID 90 von Hilscher bindet SCHIEBEL seine Stellantriebe an industrielle Kommunikationsnetze an und setzt mit einem neuen Steuerungsboard Maßstäbe.

Der Anlagenbau-Spezialist Güdel aus der Schweiz realisiert mit netFIELD fortschrittliche IIoT-Lösungen von der punktuellen Verschleißüberwachung bis zum ganzheitlichen Industrie-4.0-Ansatz.

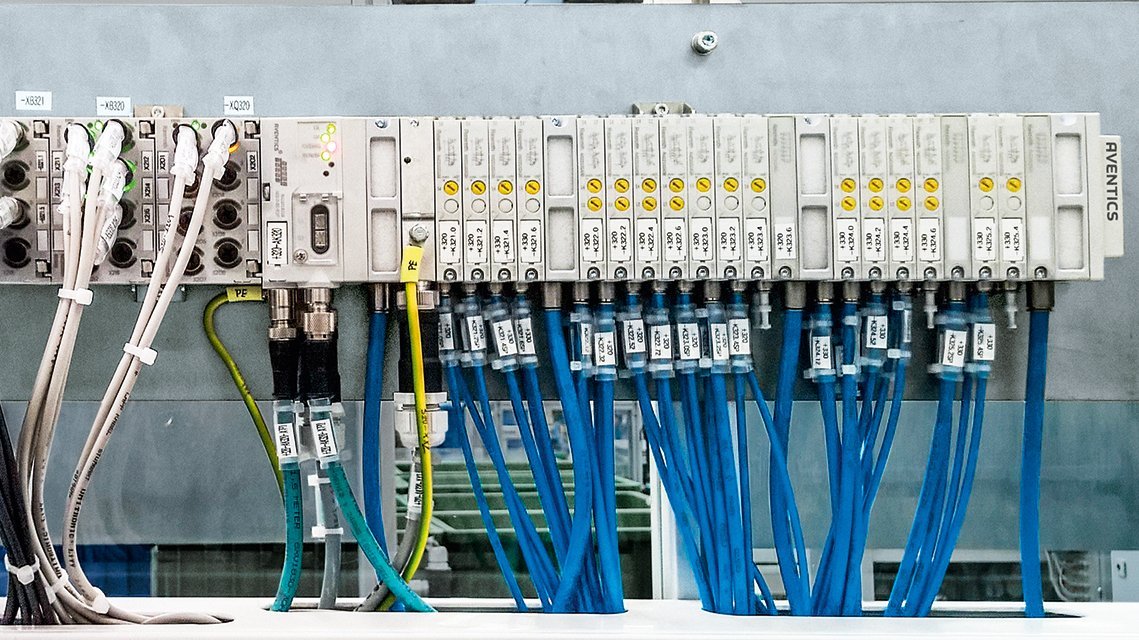

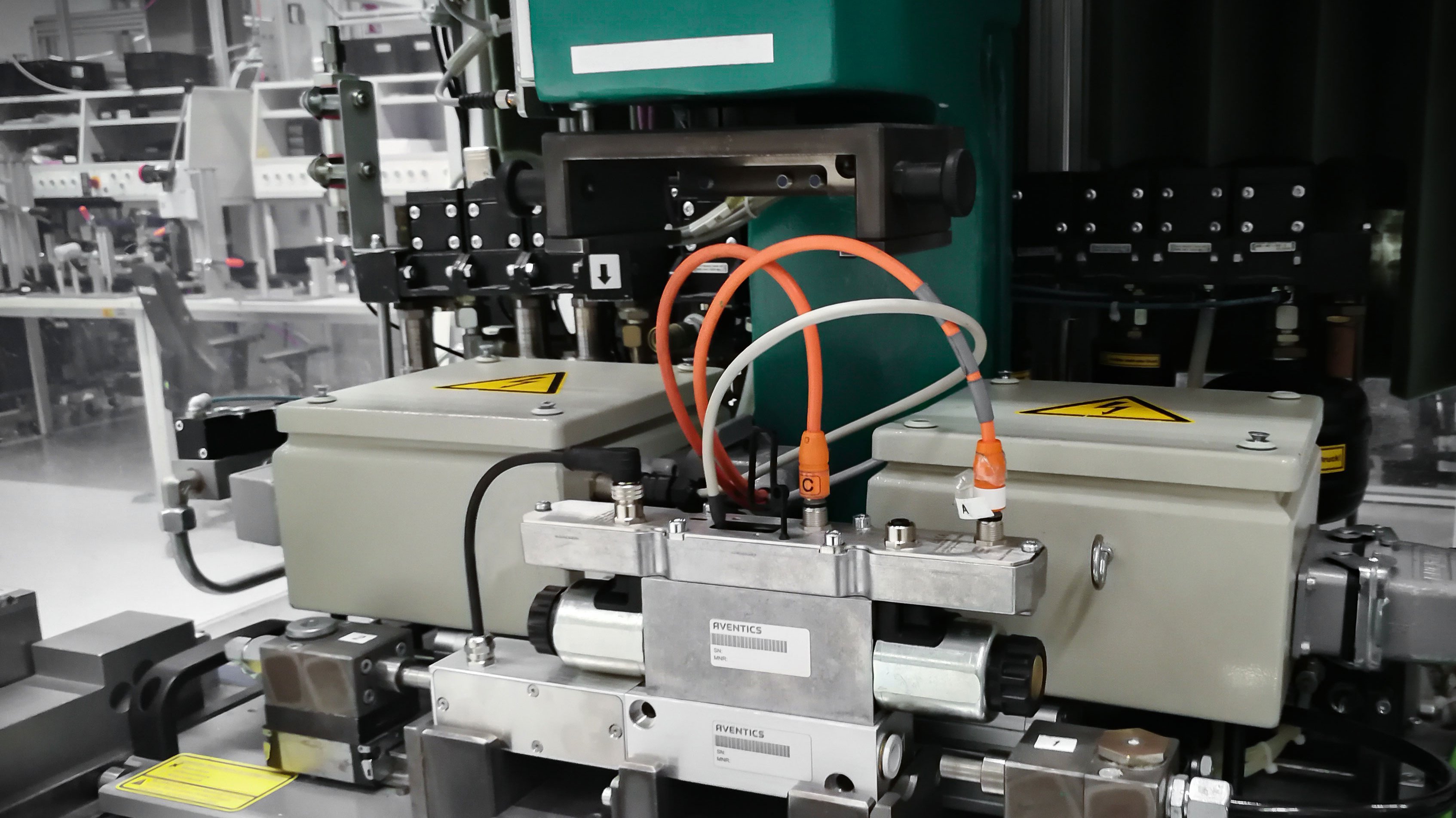

Emerson, ein weltweit führender Anbieter von Automatisierungstechnik und Software, aktiviert OPC UA in den AVENTICS™-Ventilsystemen und vereinfacht die IIoT-Integration und Analysefähigkeiten mit dem netX90.

Systemtechnik LEBER und E-T-A entwickeln mit Hilfe des netX 90 einen platzsparenden und preissensitiven Buscontroller zur Überwachung elektronischer Sicherungsautomaten.

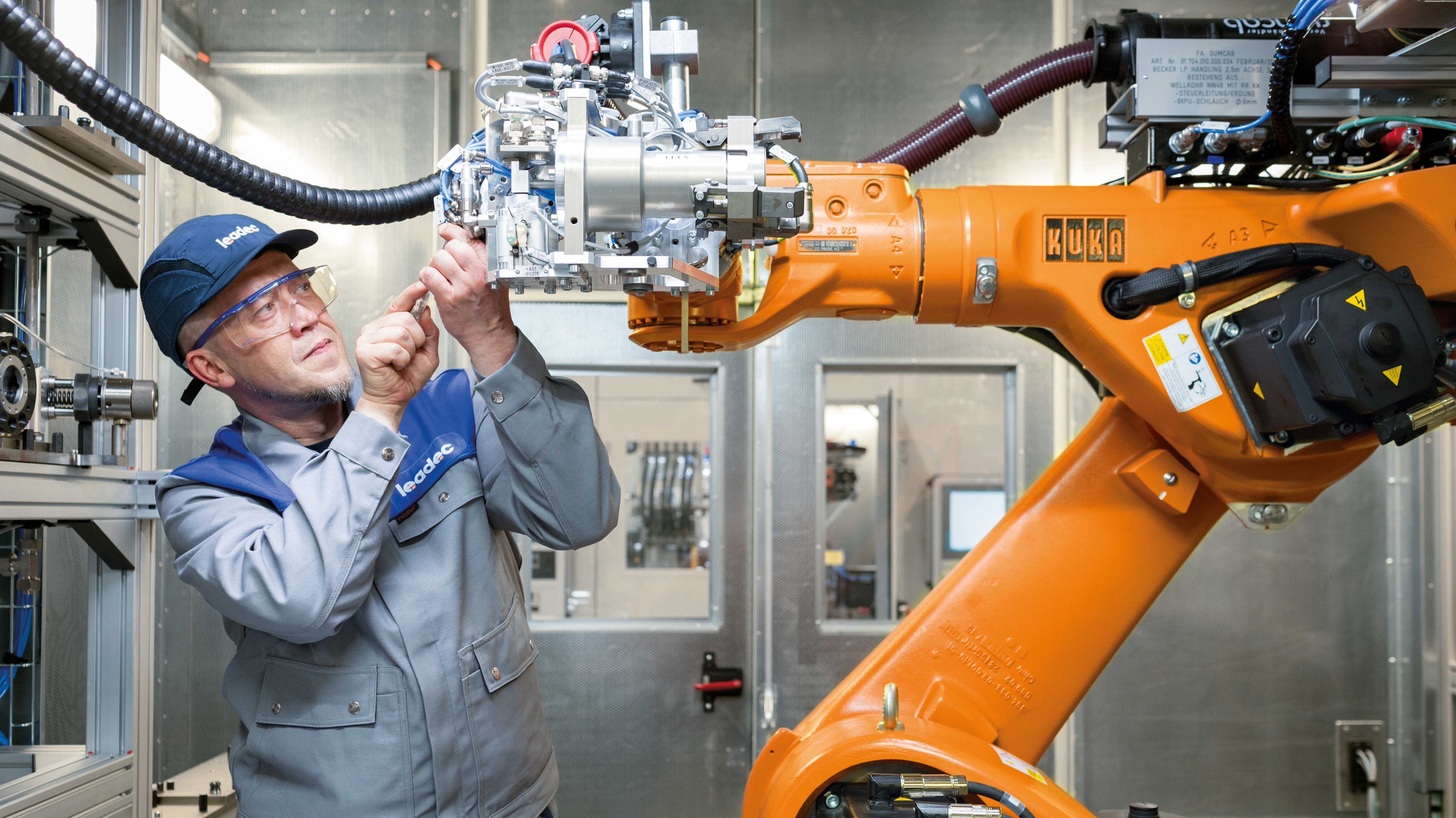

netANALYZER unterstützt den Servicespezialisten Leadec zuverlässig bei der Fehlersuche in Real-Time-Ethernet-Netzwerken.

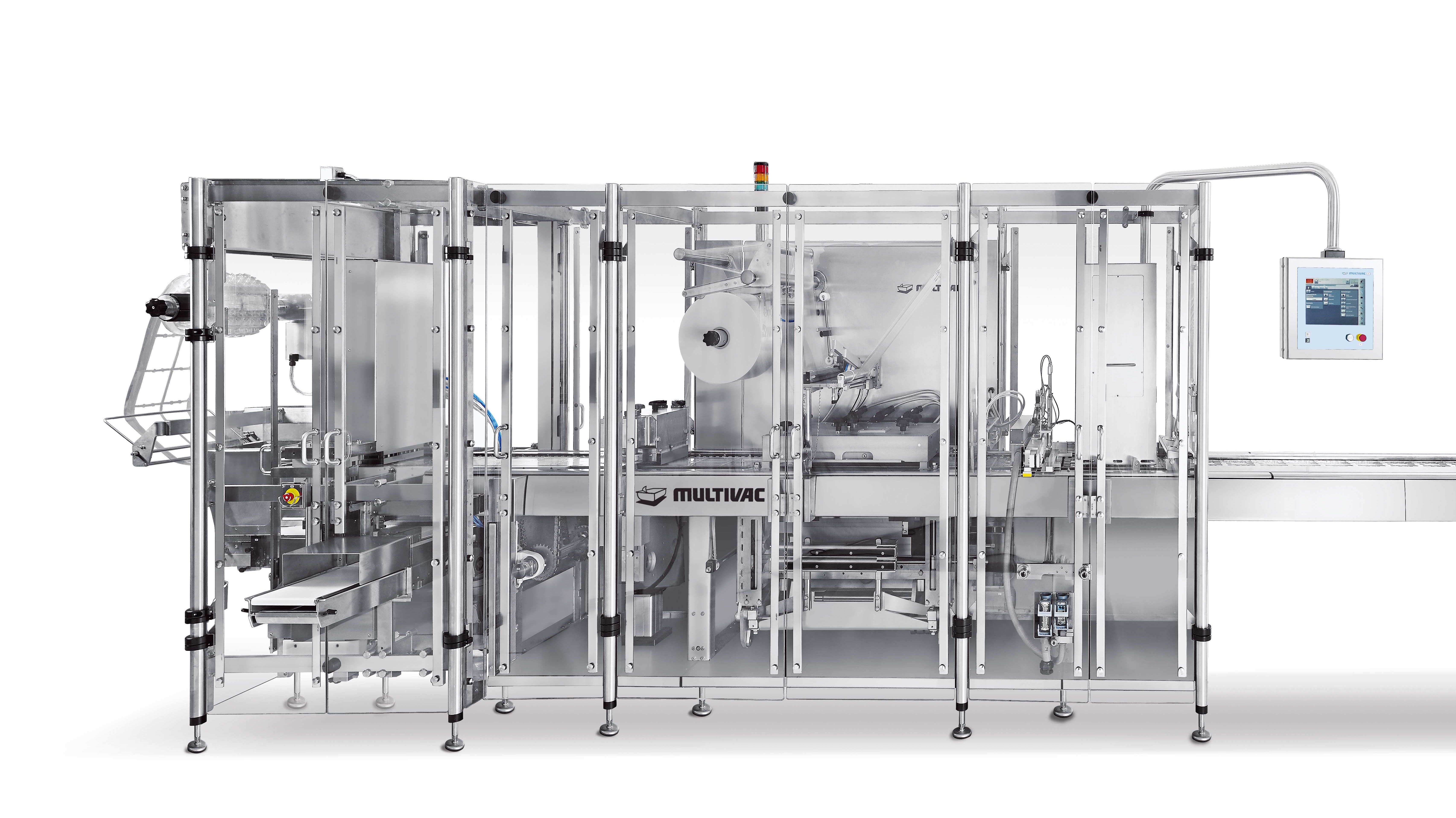

Der führende Hersteller integrierter Verpackungslösungen MULTIVAC entwickelt kundenorientierte Services und ermöglicht höhere Maschinenverfügbarkeit mit netFIELD.

netTAP 151 bietet eine flexible und skalierbare Lösung für die einfache Integration unabhängiger Verarbeitungssysteme in ein industrielles Kommunikationsnetzwerk.

Die müller+krahmer GmbH realisiert mit Hilschers cifX-PC-Karten Pneumatik-Prüfstände mit on-the-fly-Protokollwechsel.

Für die Entwicklung innovativer Produkte setzt das Ingenieurbüro kumkeo GmbH als eines der ersten Unternehmen auf den netX 90, den weltweit kleinsten Multiprotokollchip von Hilscher.

IPC Spezialist ADS-TEC Industrial IT nutzt das Optionsmodul netJACK als universelle Lösung, um seine industriellen Box PCs und HMIs bedarfsorientiert, flexibel und werkzeuglos mit Master- und Slave-Funktionalitäten auszurüsten.

Der Antriebshersteller NORD DRIVESYSTEMS realisiert mit netX kompaktere Baugröße und vereinfacht Servicing.

netMIRROR ermöglicht dem Fabrik-Servicespezialisten Leadec die schnelle und zuverlässige Fehlersuche in Real-Time-Ethernet Netzwerken.

Der Bildverarbeitungsspezialist VITRONIC integriert mit den cifX-PC-Karten automatisierte Systeme für die Prüfung von Schweißnähten in eine Vielzahl von Real-Time-Ethernet- und Feldbus-Netzwerken.

Sie sind auf der Suche nach einem Integrationspartner für Ihr industrielles Kommunikationsprojekt? Von multiprotokollfähigen netX-Chips bis IIoT-Anwendungen – unser Netzwerk aus Partnerunternehmen bietet Ihnen den Support, den Sie benötigen!

Durch unsere Lösungen kommunizieren weltweit Maschinen automatisiert und sicher miteinander. Von Kommunikations-Controllern über PC-Karten und Embedded-Module bis hin zu Netzwerkanalyse und Industrie 4.0 – wir ermöglichen industrielle Kommunikation. Lesen Sie unsere Success Stories.

Wir machen industrielle Kommunikation möglich. Vom Legacy-Feldbus über Real-Time-Ethernet bis in die Cloud. Unsere Lösungen sind multiprotokollfähig, flexible und zuverlässig. Erfahren Sie mehr darüber, wie unsere netX Software- und Hardware-Technologien funktionieren und wie wir mit unserer IIoT-Plattform netFIELD Maschinendaten für Sie zugänglich machen.