Alle Typen von Steuerungsarchitekturen benötigen und beinhalten unweigerlich Kommunikationslösungen wie Real-Time-Ethernet- oder Feldbusnetzwerke. Durch die steigende Intelligenz von Netzwerkteilnehmern wie Sensoren und Aktoren wächst das Datenaufkommen zwischen Feldgeräten und Steuerungen erheblich. Als Hersteller von Steuerungssystemen müssen Sie Ihre Geräte und deren Kommunikationsschnittstellen immer leistungsstärker konzipieren, um künftigen Anforderungsprofilen zu entsprechen. Unsere flexiblen und hochperformanten Lösungen für die industrielle Kommunikation unterstützen Sie dabei. Ob schnellere Aktualisierung von IO-Daten oder netzwerkübergreifender Echtzeitaustausch von Diagnoseinformationen: die innovativen Hilscher-Lösungen eröffnen Ihnen mit konsistenten Kommunikationskonzepten neue Möglichkeiten.

Herausforderungen für Steuerungshersteller

Zunehmende Netzwerkintelligenz

Die Anforderungen an Steuerungsgeräte wachsen mit der zunehmenden Intelligenz und Vernetzung industrieller Netzwerke. Für Sie als Hersteller ist es wichtig, durch die Wahl der richtigen Komponenten auch für künftige Szenarien gerüstet zu sein. Profitieren Sie heute von unserem breiten Portfolio und unserer Innovationskraft für die Lösungen von morgen.

Flexibilität und Variabilität

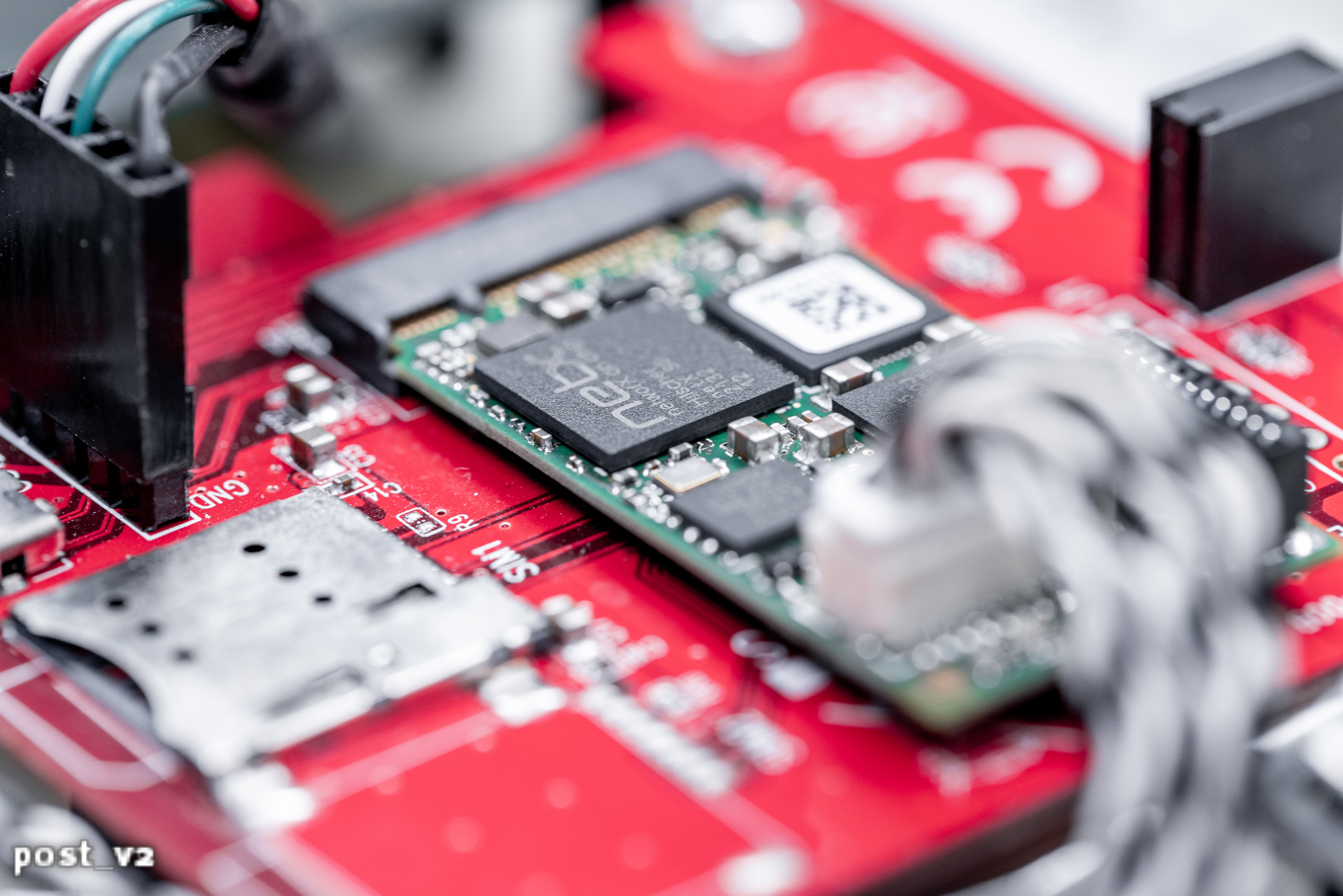

Die globalen Märkte erfordern verschiedenste Kommunikationsprotokolle. Möglichst einfache Protokollwechsel sind Ihr Schlüssel, neue Zielmärkte schnell und mit geringem Aufwand zu adressieren. Mit unserer multiprotokollfähigen netX-Technologie sowie standardisierten Schnittstellen, Treibern und Tools gewährleisten wir maximale Flexibilität für Sie.

Komponenten für Master-Protokolle

Fertige nutzbare Kommunikationsbausteine mit Master-Funktionalitäten für Steuerungen sind auf dem Automatisierungsmarkt kaum vorhanden. Hilscher ist marktführender Anbieter für Multiprotokolllösungen. Wir unterstützen Sie je nach Zielsystem mit einer passenden Lösung für Master-Protokolle. Unsere Hardware, Software und Tools sind dabei optimal aufeinander abgestimmt – Sie konzentrieren sich ganz auf die Entwicklung Ihrer Anwendung.

Basierend auf unserer netX-Technologie kommen unsere Kommunikations-Controller, Embedded-Module und PC-Karten weltweit in unzähligen Steuerungssystemen zum Einsatz. Aufbauend auf unserem jahrzehntelangen Know-how integrieren Sie Ihre Steuerung zuverlässig in moderne Feldbus- und Real-Time-Ethernet-Netzwerke. Unser markführendes und vielfältiges Produktportfolio hält für jeden Anwendungsfall die passende Lösung bereit, unabhängig von den geforderten Netzwerkstandards.

Dank unserer Hilscher-Plattformstrategie verfügen alle Produkte über einheitliche Schnittstellen, Treiber und Tools. Auch serviceseitig können Sie sich auf unsere Unterstützung verlassen – z.B. beim individuellen Design Ihres Gerätes oder den Zertifizierungsprozessen. Dank der Zuverlässigkeit und Langzeitverfügbarkeit unserer Produkte entscheiden Sie sich bei Hilscher für nachhaltige Lösungen – zum Beispiel in den Bereichen:

- Lasersteuerungen

- Steuerungssysteme (Elektronikfertigung und Automatisierungstechnik)

- HMI-Steuerungen

- Honsteuerungen

- SPSen

- Kransteuerungen (auch remote)

- Brennersteuerung

- Steuerung für Minimalmengenschmierung

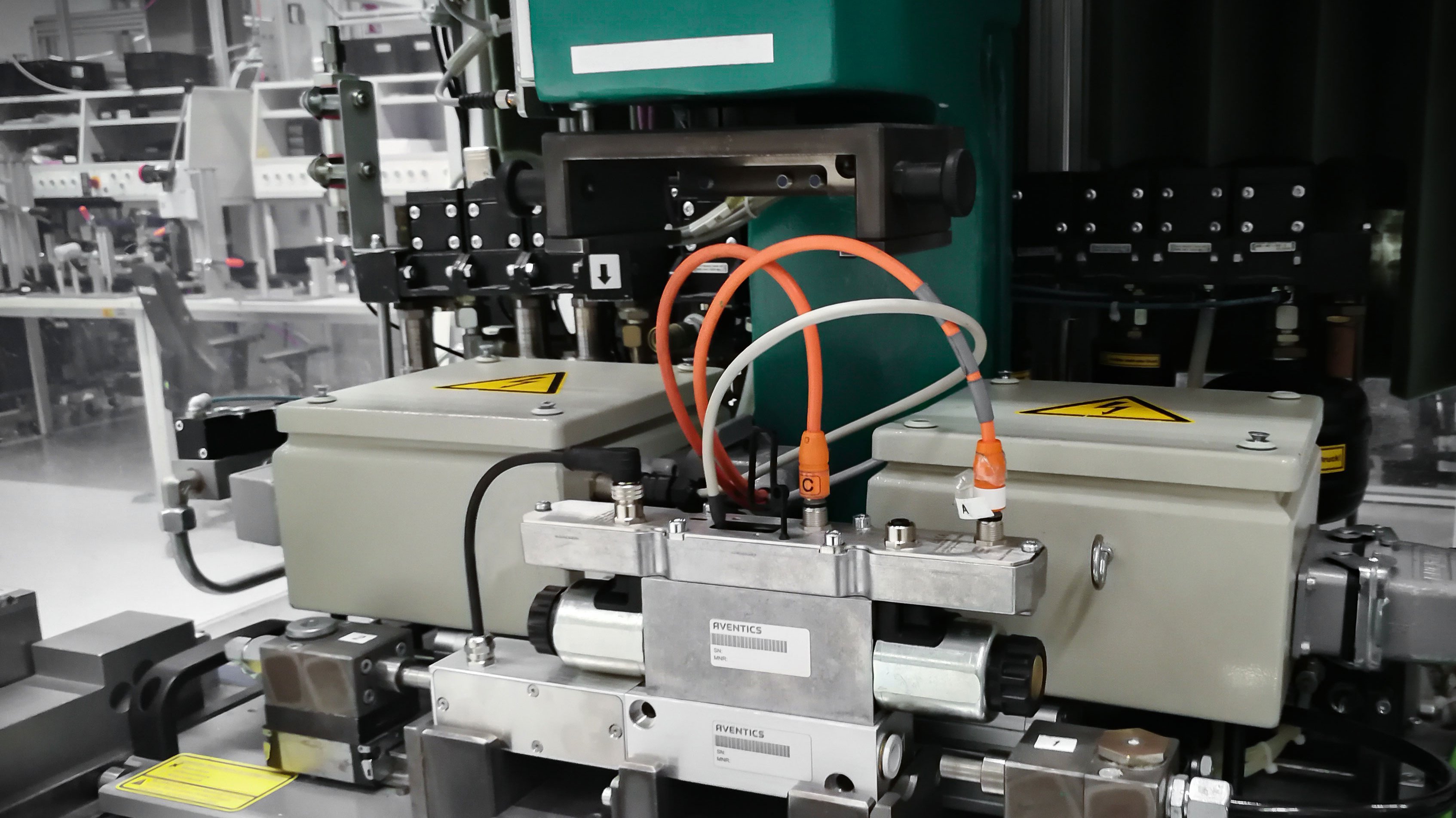

- Pneumatische Steuersysteme

- Steuerungen für Wärmebehandlungsöfen

- Schwankungs- und Schräglagenkontrollsysteme für Verladeportale

- Gerätesteuerungen

Orange Precision Measurement implements PROFINET, EtherCAT, and EtherNet/IP as well as DeviceNet using Hilscher's netX 90 multiprotocol communication controller, enabling the American manufacturer of precision measurement tools to supply its products to various customers.

Der Flagship Store von Hilscher für die Open Industry 4.0 Alliance (OI4) Community zeigt die Einfachheit von App Stores in der Industrie. Anwender können damit Apps und Lösungen für die Automatisierung nutzen – geschützt und lizensiert mit CodeMeter von Wibu-Systems.

Oerlikon Metco AG, ein führender Anbieter von Oberflächenlösungen, setzt netFIELD ein, um die Echtzeit-Datenerfassung von Industriemaschinen wie thermischen Spritzanlagen weltweit zu ermöglichen.

Vom Motorcontroller bis zur Konsolidierung gesamter Schaltschrankinhalte realisieren dieEntwickler Elektronik (dEE) innovative netX-90-Projekte und erschließen die gesamte interne Peripherie des kleinen Multiprotokollcontrollers.

Mit den Embedded-Modulen netIC 52 und netRAPID 90 von Hilscher bindet SCHIEBEL seine Stellantriebe an industrielle Kommunikationsnetze an und setzt mit einem neuen Steuerungsboard Maßstäbe.

Der Anlagenbau-Spezialist Güdel aus der Schweiz realisiert mit netFIELD fortschrittliche IIoT-Lösungen von der punktuellen Verschleißüberwachung bis zum ganzheitlichen Industrie-4.0-Ansatz.

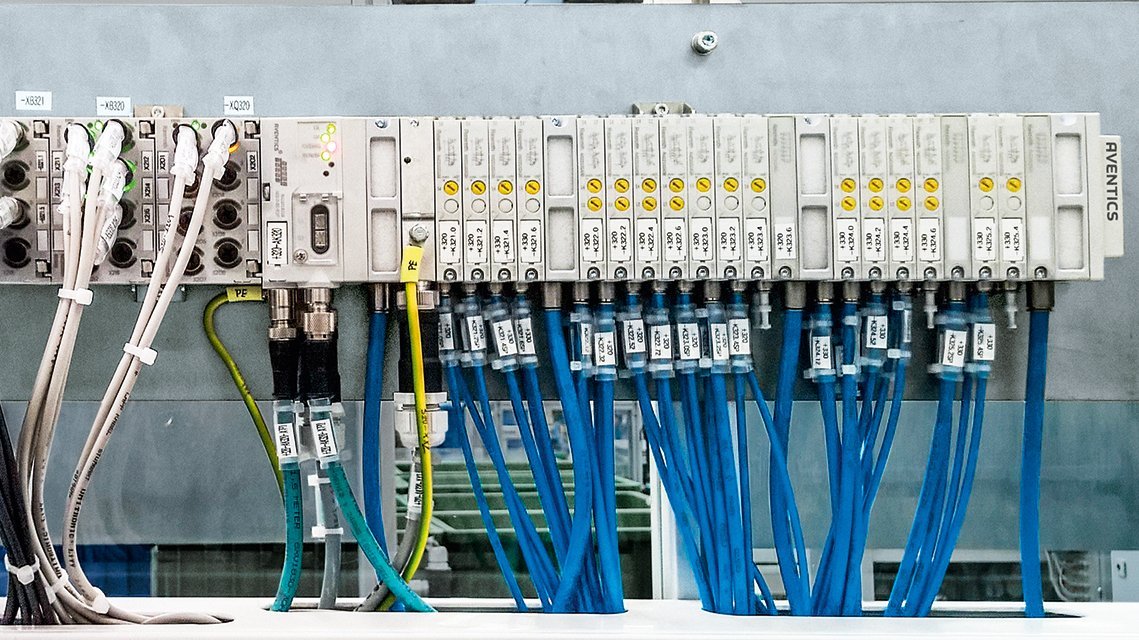

Emerson, ein weltweit führender Anbieter von Automatisierungstechnik und Software, aktiviert OPC UA in den AVENTICS™-Ventilsystemen und vereinfacht die IIoT-Integration und Analysefähigkeiten mit dem netX90.

Systemtechnik LEBER und E-T-A entwickeln mit Hilfe des netX 90 einen platzsparenden und preissensitiven Buscontroller zur Überwachung elektronischer Sicherungsautomaten.

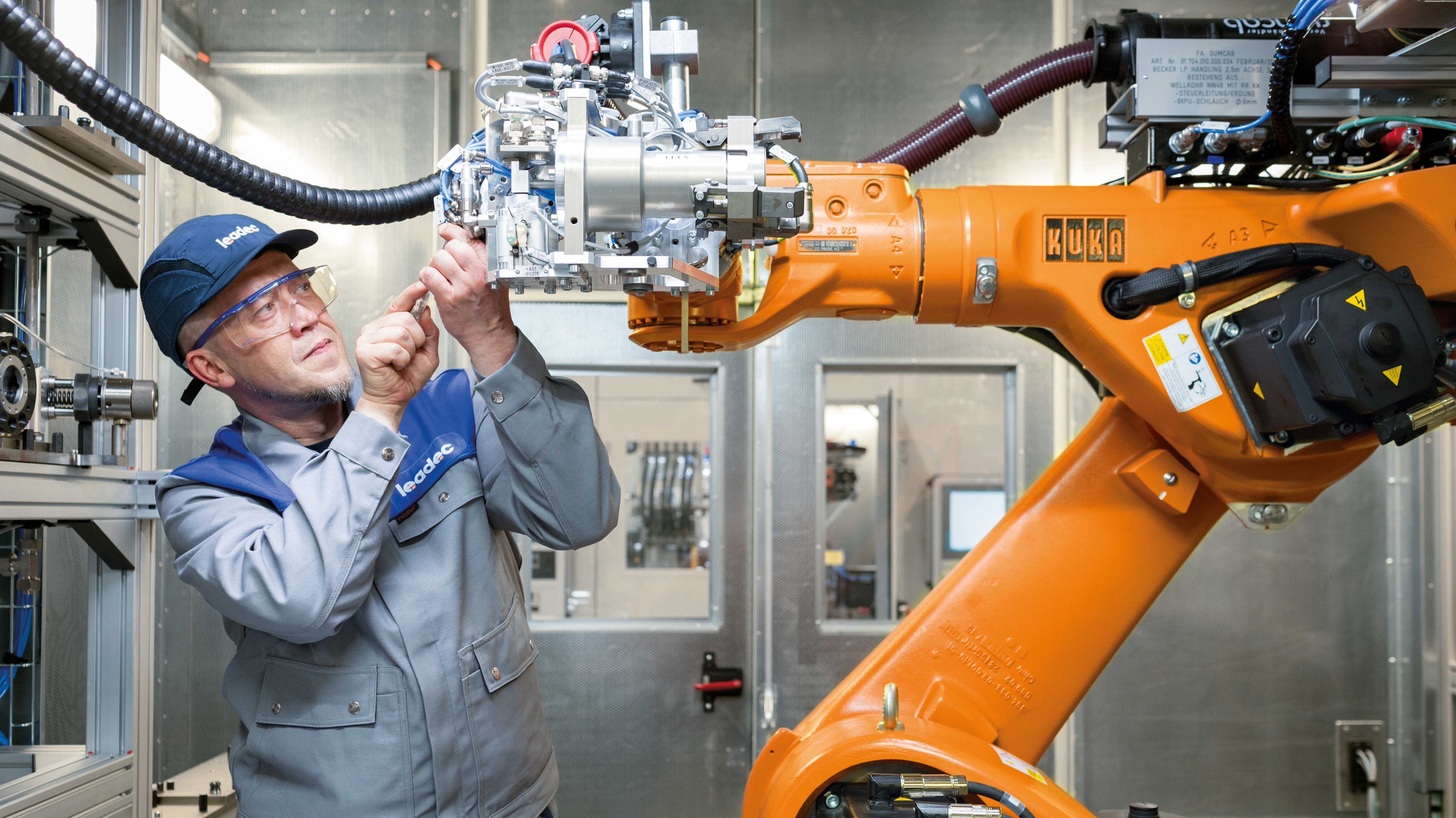

netANALYZER unterstützt den Servicespezialisten Leadec zuverlässig bei der Fehlersuche in Real-Time-Ethernet-Netzwerken.

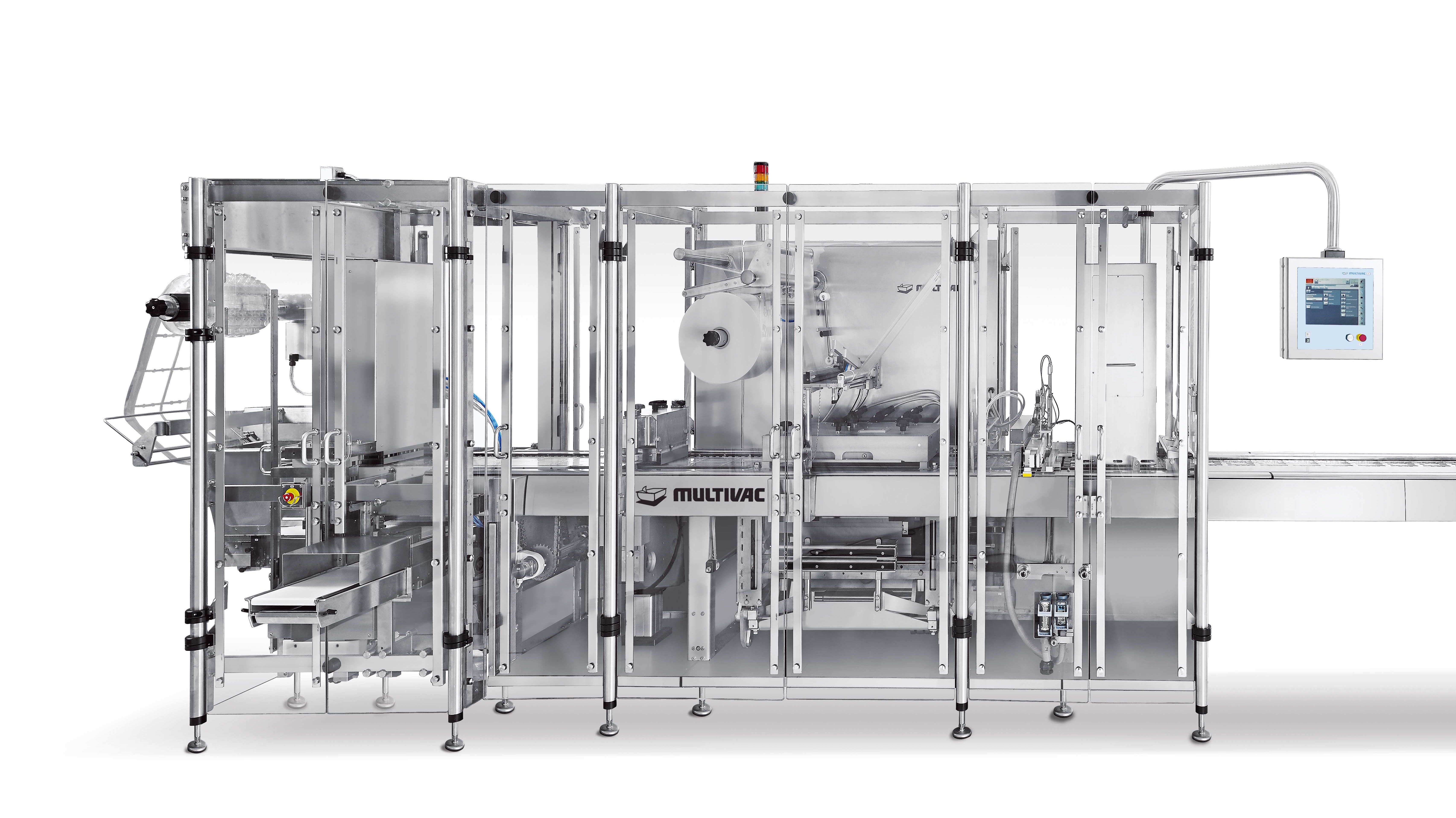

Der führende Hersteller integrierter Verpackungslösungen MULTIVAC entwickelt kundenorientierte Services und ermöglicht höhere Maschinenverfügbarkeit mit netFIELD.

netTAP 151 bietet eine flexible und skalierbare Lösung für die einfache Integration unabhängiger Verarbeitungssysteme in ein industrielles Kommunikationsnetzwerk.

Die müller+krahmer GmbH realisiert mit Hilschers cifX-PC-Karten Pneumatik-Prüfstände mit on-the-fly-Protokollwechsel.

Für die Entwicklung innovativer Produkte setzt das Ingenieurbüro kumkeo GmbH als eines der ersten Unternehmen auf den netX 90, den weltweit kleinsten Multiprotokollchip von Hilscher.

IPC Spezialist ADS-TEC Industrial IT nutzt das Optionsmodul netJACK als universelle Lösung, um seine industriellen Box PCs und HMIs bedarfsorientiert, flexibel und werkzeuglos mit Master- und Slave-Funktionalitäten auszurüsten.

Der Antriebshersteller NORD DRIVESYSTEMS realisiert mit netX kompaktere Baugröße und vereinfacht Servicing.

netMIRROR ermöglicht dem Fabrik-Servicespezialisten Leadec die schnelle und zuverlässige Fehlersuche in Real-Time-Ethernet Netzwerken.

Der Bildverarbeitungsspezialist VITRONIC integriert mit den cifX-PC-Karten automatisierte Systeme für die Prüfung von Schweißnähten in eine Vielzahl von Real-Time-Ethernet- und Feldbus-Netzwerken.

Sie sind auf der Suche nach einem Integrationspartner für Ihr industrielles Kommunikationsprojekt? Von multiprotokollfähigen netX-Chips bis IIoT-Anwendungen – unser Netzwerk aus Partnerunternehmen bietet Ihnen den Support, den Sie benötigen!

Durch unsere Lösungen kommunizieren weltweit Maschinen automatisiert und sicher miteinander. Von Kommunikations-Controllern über PC-Karten und Embedded-Module bis hin zu Netzwerkanalyse und Industrie 4.0 – wir ermöglichen industrielle Kommunikation. Lesen Sie unsere Success Stories.

Wir machen industrielle Kommunikation möglich. Vom Legacy-Feldbus über Real-Time-Ethernet bis in die Cloud. Unsere Lösungen sind multiprotokollfähig, flexible und zuverlässig. Erfahren Sie mehr darüber, wie unsere netX Software- und Hardware-Technologien funktionieren und wie wir mit unserer IIoT-Plattform netFIELD Maschinendaten für Sie zugänglich machen.