While the factory automation networks largely base on Ethernet standards today, the adoption of Ethernet in the process automation field is still in progress. To address and enable business models for Industrie 4.0 and Industrial Internet of Things, the Namur released an open architecture (NOA) defining a communication concept across all layers to the cloud. Namur also released a paper to determine future networks in process automation to be IP networks with Ethernet. The FieldComm Group together with PI and ODVA formed a group that has driven the progress in IEEE to a large extend and determined their system requirements for a fast adoption into the field.

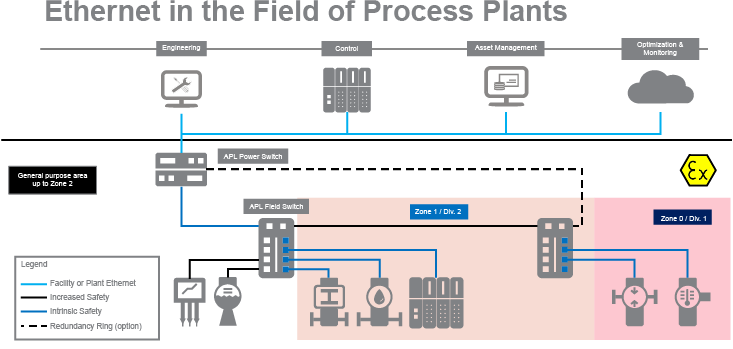

The picture shows the different zones in a process plant to address different levels of intrinsic safety and loop-powered or separate powered devices in hazardous areas like in Zone 0. The network itself uses the well-known spur and trunk topology that includes the ability to power up to 50 devices with up to 500mA each. Furthermore, existing cables and installations can be reused to reduce the effort of system design and integration time. Hence, the focus of the process industry is to replace the existing fieldbus installations with APL continuously.