Automation as part of Industry 4.0 requires real-time communication capability of all relevant components in devices and production facilities—from sensors and actuators to control elements. As a manufacturer, by integrating industrial communication interfaces into your components, you're helping to maximize the availability of industrial processes while ensuring that processes run smoothly. At Hilscher, we are dedicated to helping you do just that—and to developing efficient solutions to your biggest challenges with our products and services:

Components in automated environments

Integration Cost

Components for automated equipment and systems are used in a variety of mostly highly individual production systems. However, as a manufacturer, you want to keep the integration workload as low as possible in order to save costs and minimize the time-to-market for your customers.

Continuity

The automation market is in a state of constant flux. Companies are constantly innovating new products, new devices and new standards—we help you make them work for you. Our communication solutions are available for years and can be upgraded to include the latest trends and standards. With netX and Hilscher you are well prepared for the future.

Flexibility and Variability

As a component manufacturer, you want to target a variety of different markets. The key is to support all relevant protocols, standards, and interfaces. But this presents different challenges depending on your region and technology. Components for automated devices must therefore offer a high degree of flexibility and variability.

As specialists in the field of industrial communication, we have made it our mission to provide component manufacturers with the best possible support in the form of easy-to-use and flexible solutions. As a member of leading committees and professional associations, we have an eye on the trends and include them in our roadmap. With our wide range of products, we also have the right solution for your application and we're happy to help you with our engineering and consulting services. We've already equipped a wide range of components with industrial communication, including:

- I/O devices

- Measuring instruments

- Power supplies

- Gateways

- Industrial PCs

Orange Precision Measurement implements PROFINET, EtherCAT, and EtherNet/IP as well as DeviceNet using Hilscher's netX 90 multiprotocol communication controller, enabling the American manufacturer of precision measurement tools to supply its products to various customers.

Hilscher’s Flagship Store for the Open Industry 4.0 Alliance (OI4) Community brings the ease of app stores to the industrial world. Powered by Wibu-Systems' CodeMeter licensing, the store gives users access to a library of apps and solutions for their shop floor automation needs.

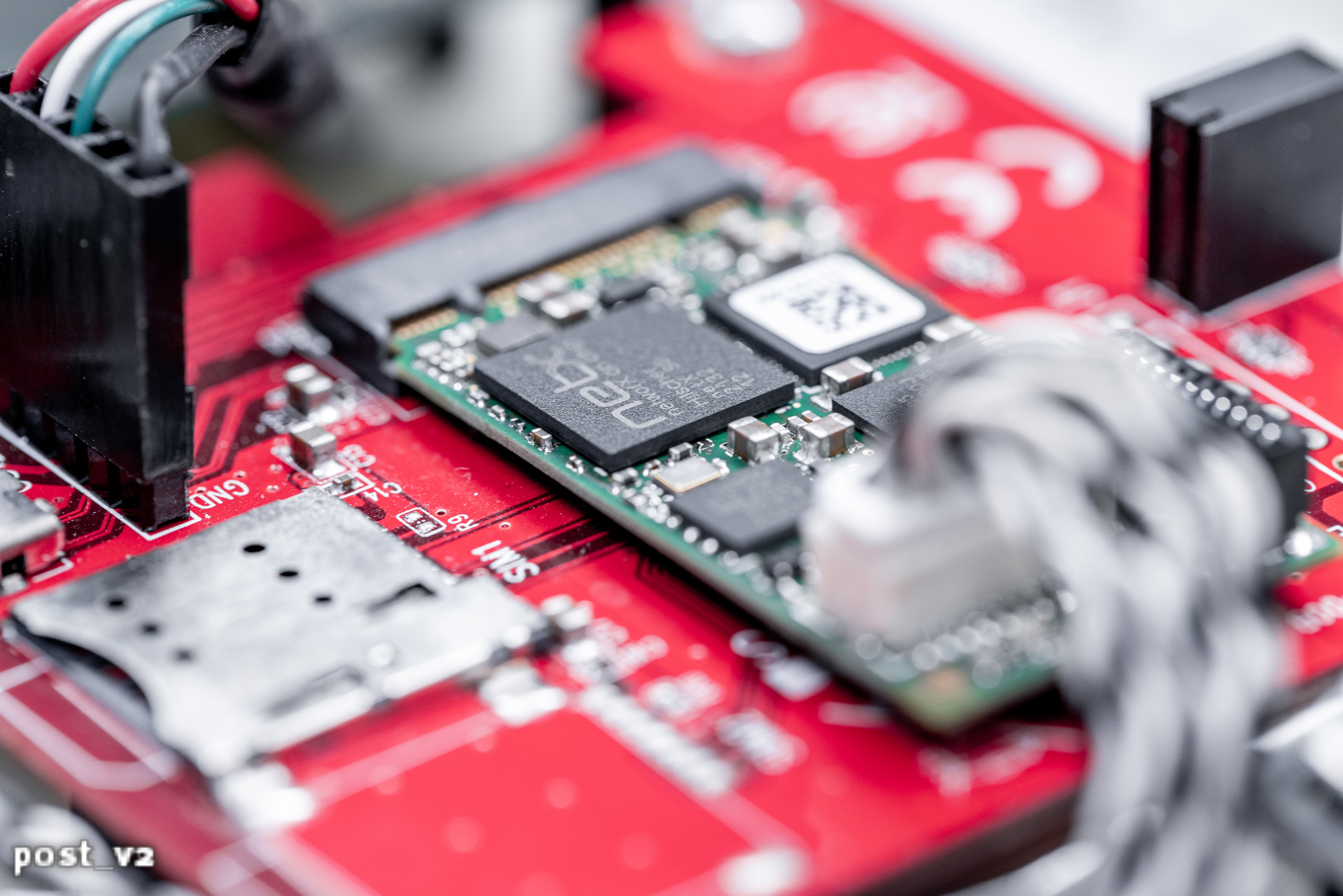

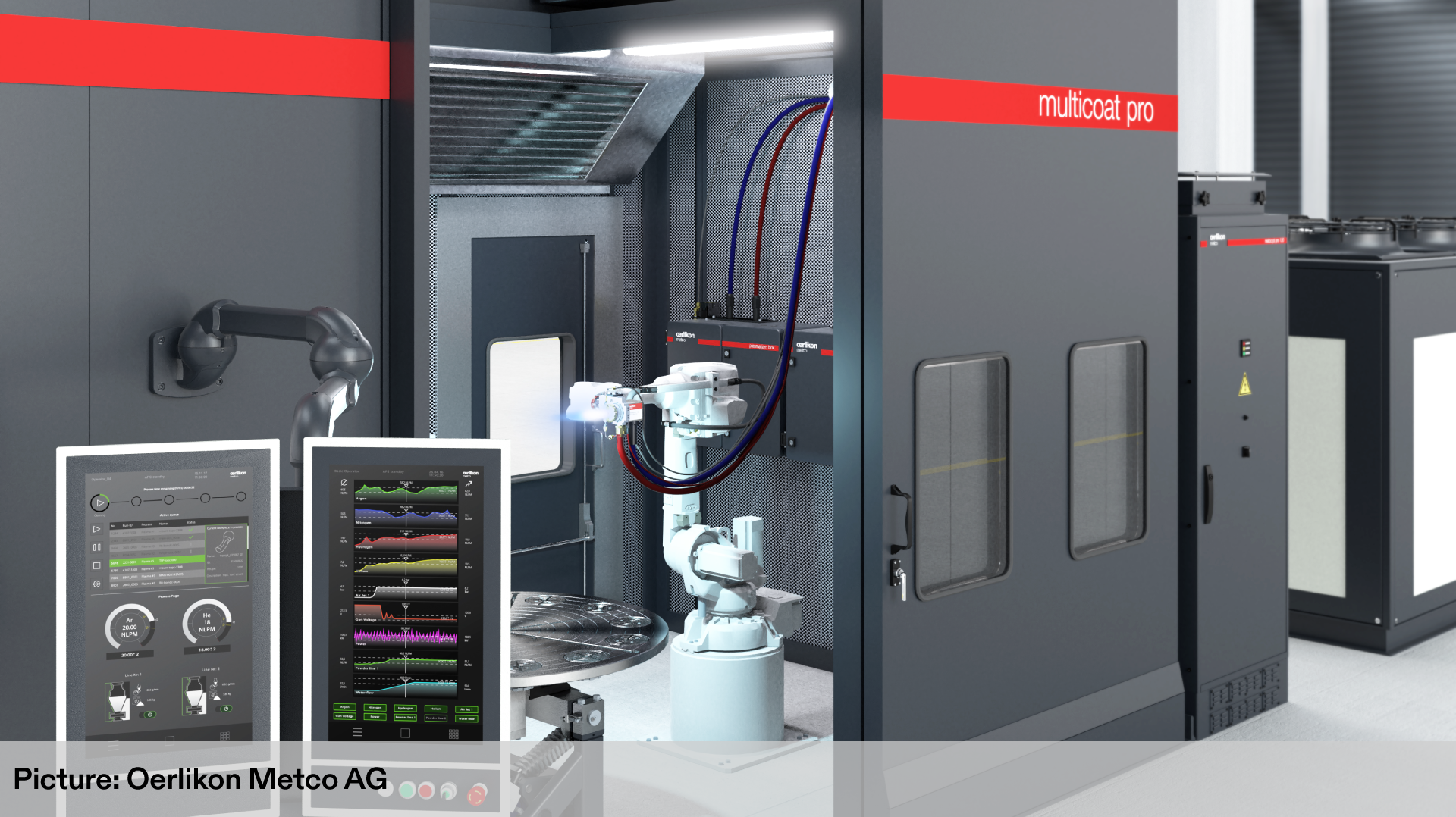

Surface solution specialist Oerlikon Metco AG uses netFIELD to enable real-time data collection from industrial applications, such as thermal spray painting machines, from around the world.

From motor controllers to the consolidation of entire control cabinet contents, dieEntwickler Elektronik (dEE) implements innovative netX 90 projects and opens up the entire internal periphery of the small multiprotocol controller. Read more about our integration partner here!

With the embedded modules netIC52 and netRAPID 90 from Hilscher, SCHIEBEL connects its actuators to industrial communication networks and sets standards with a new control board.

Industrial systems specialist Güdel uses netFIELD to implement advanced IIoT solutions, ranging from monitoring specific wear points to a more holistic Industry 4.0 approach.

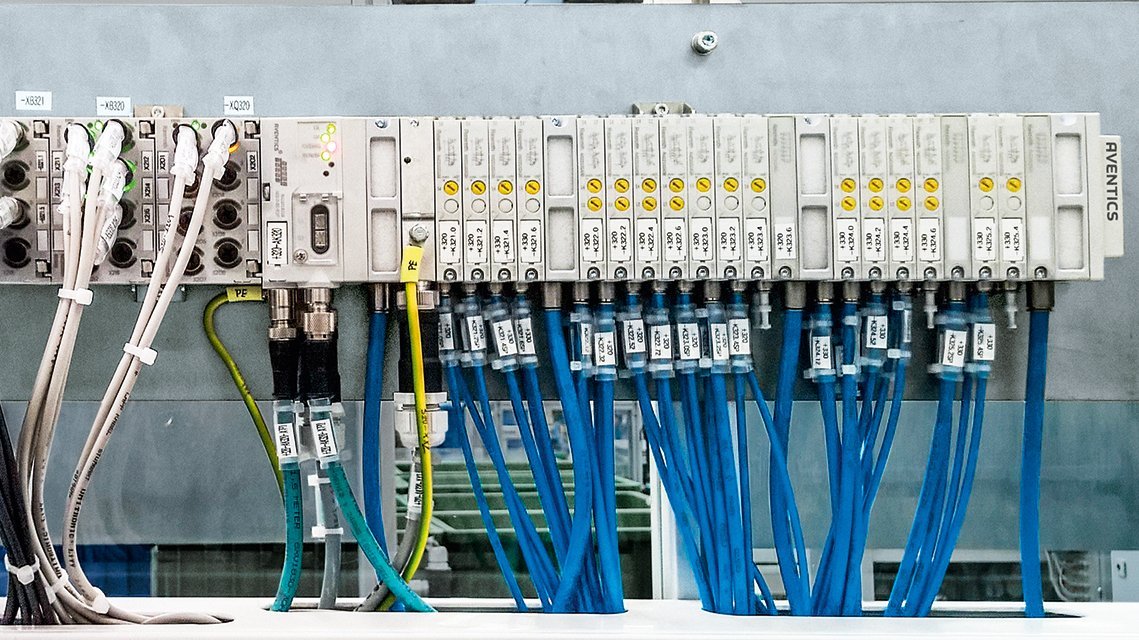

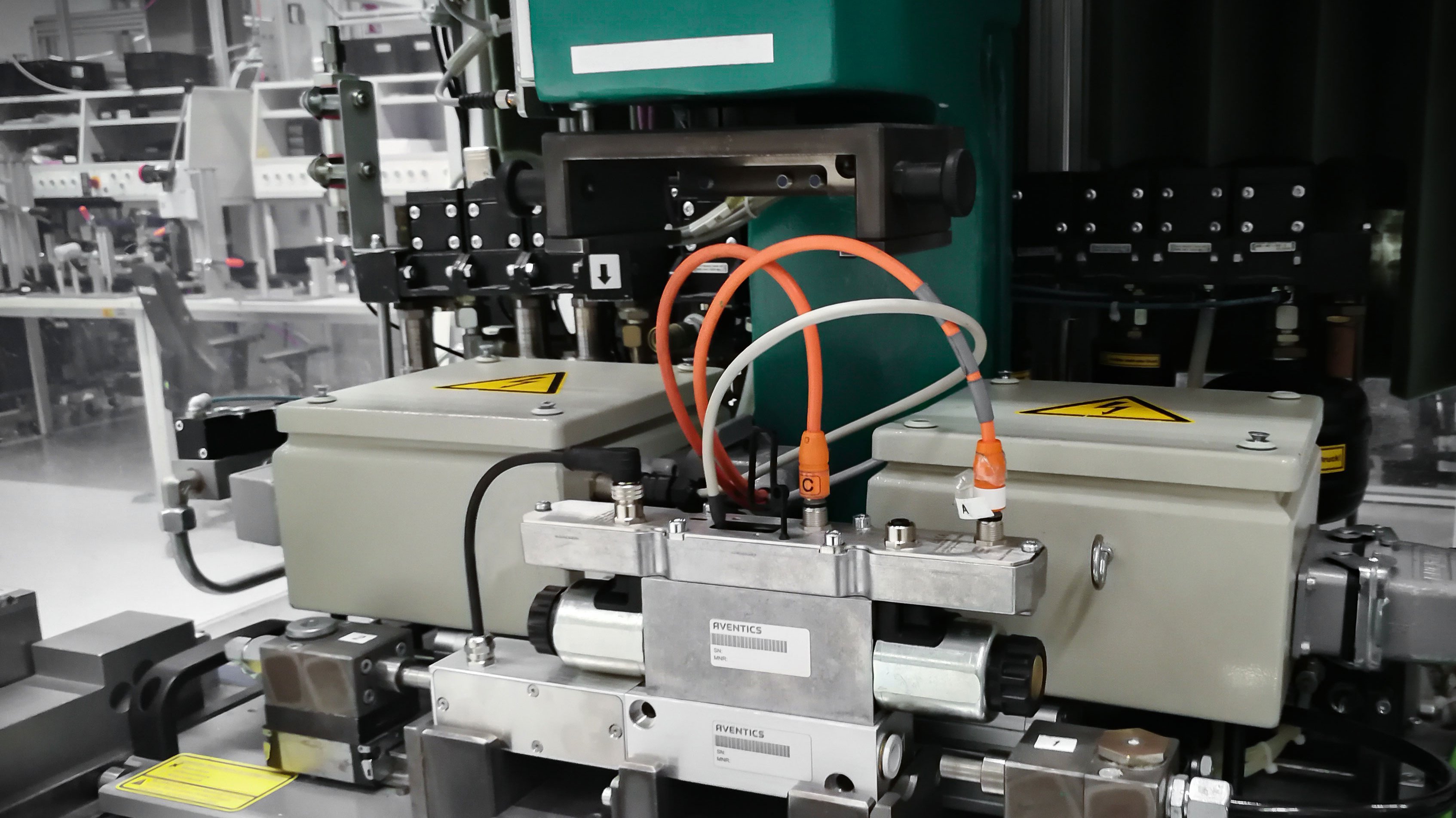

Emerson, a world leading provider of automation technology and software, has enabled integrated OPC UA in their AVENTICS™ valve systems, simplifying IIoT integration and analysis capabilities with netX 90.

Based on Hilscher’s netX 90 multiprotocol processor, Systemtechnik LEBER and E-T-A developed an ultra-compact and price-sensitive bus controller for monitoring electronic circuit breakers.

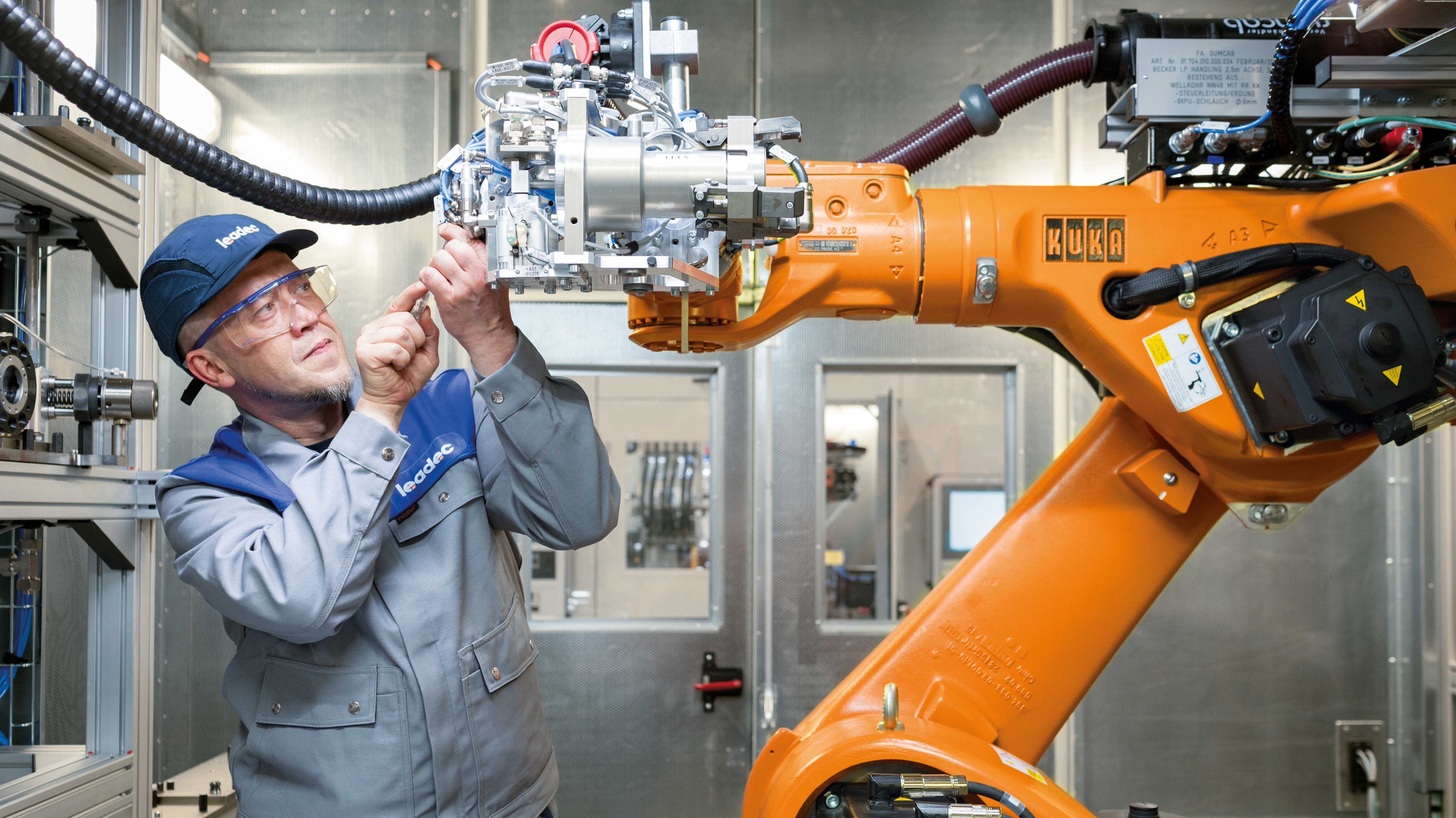

netANALYZER delivers reliable support for the service specialist Leadec in troubleshooting industrial Ethernet networks.

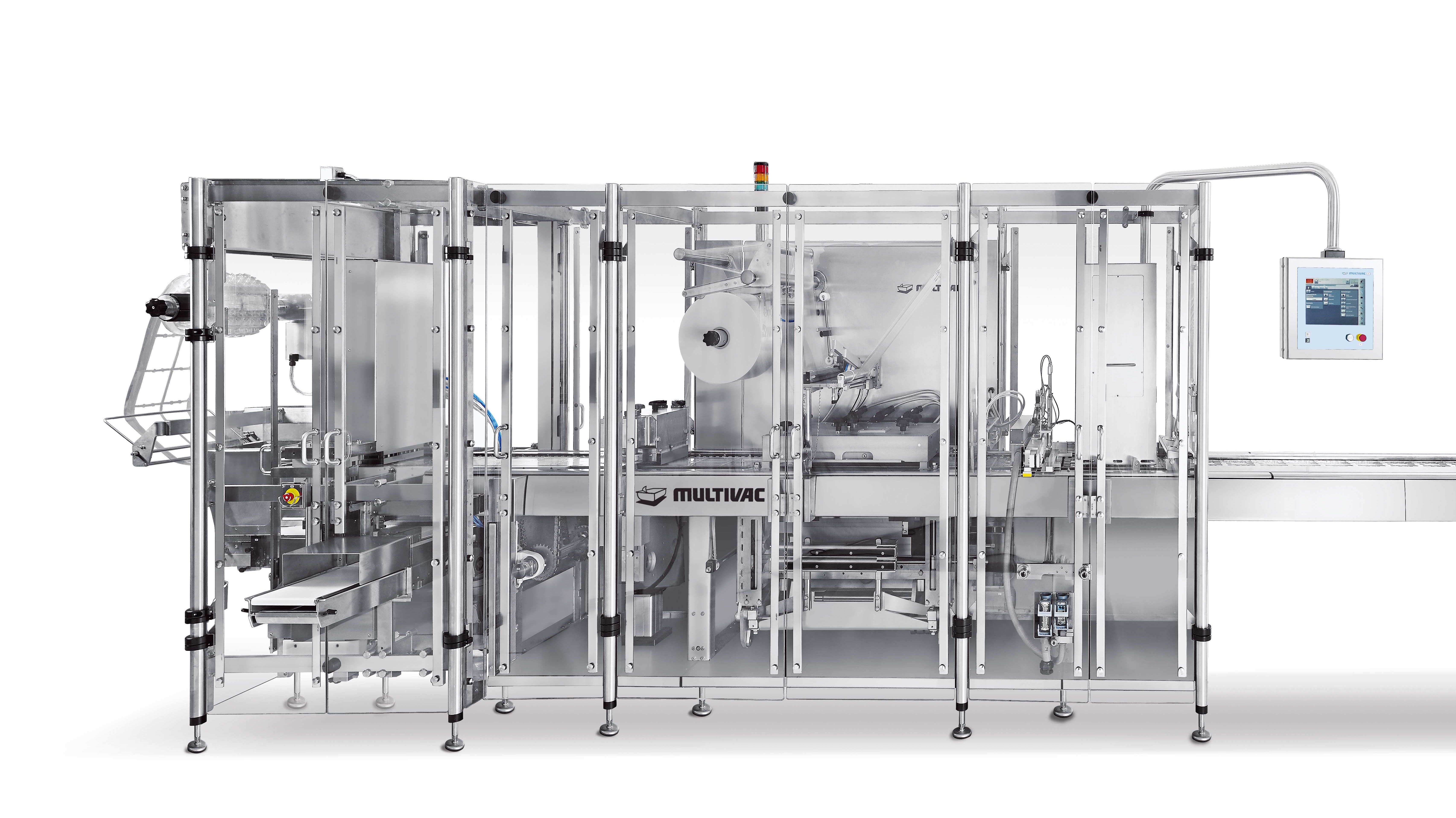

MULTIVAC, the leading manufacturer of integrated packaging solutions, develops customer-oriented services with netFIELD, enabling higher machine availability

netTAP 151 provides a flexible and scalable solution for an easy integration of independent processing systems into one industrial communication network.

müller+krahmer GmbH realizes pneumatic test benches with the capability to change protocols on the fly with the help of Hilscher cifX PC cards.

The engineering firm kumkeo GmbH is one of the first companies to rely on the netX 90, the world‘s smallest multi-protocol chip from Hilscher, for the development of innovative products.

IPC specialist ADS-TEC Industrial IT uses the netJACK option module as a universal solution to equip its Industrial Box PCs and HMIs with master and slave functionalities on demand, flexibly and without tools.

Drive manufacturer NORD DRIVESYSTEMS realizes more compact frame sizes and facilitates servicing with netX.

netMIRROR facilitates quick and reliable troubleshooting in RealTime Ethernet networks at factory service specialist Leadec.

cifX PC-Cards integrate Automated Weld Seam Inspection Systems to numerous Real-Time Ethernet and Fieldbus networks at German machine vision specialist VITRONIC.

Are you looking for an integration partner for your industrial communication project? From multi-protocol capable netX chips to IIoT applications - our network of partner companies offers you the support you need!

Our solutions enable machines all over the world to communicate autonomously and securely with each other. From communication controllers, PC cards and embedded modules to network analysis and Industry 4.0, we make industrial communication possible. Read our success stories.

We make industrial communication possible. From legacy fieldbus to Real-Time Ethernet and the cloud. Our solutions are multi-protocol capable, flexible and reliable. Learn more about how our netX software and hardware technologies work and how we make machine data accessible for you with our IIoT platform netFIELD.