OPC UA in industrial environments

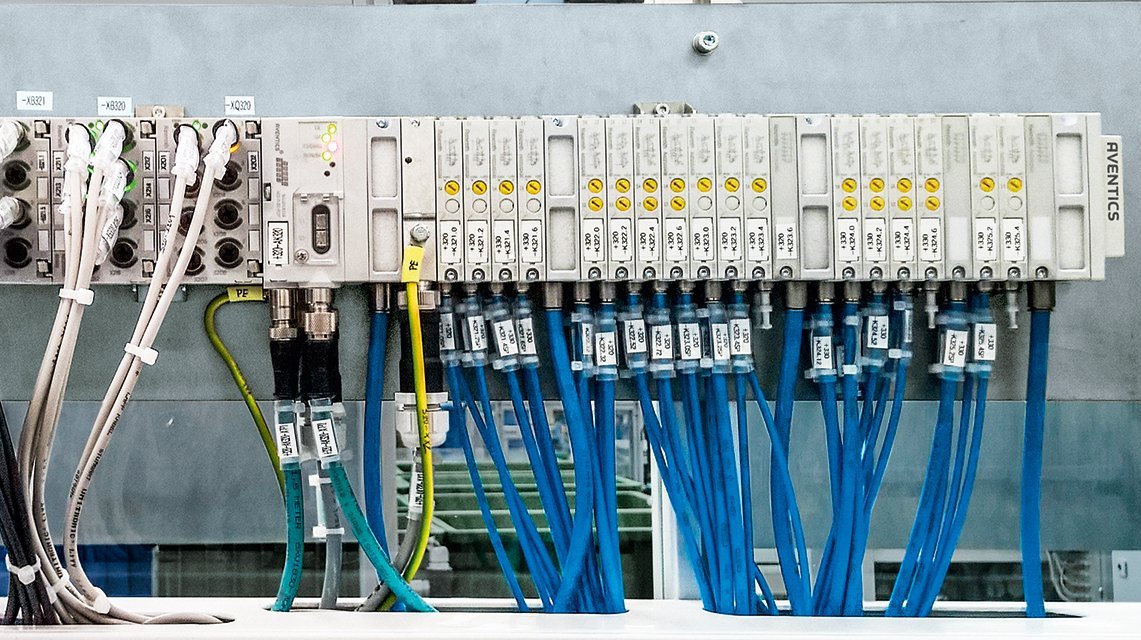

Emerson is a global technology and software company that provides innovative solutions to the world’s major industries. Through its leading automation portfolio, including its majority stake in AspenTech, Emerson helps hybrid, process and discrete manufacturers optimize their operations, protect their employees’ privacy, reduce emissions, and achieve their sustainability goals. With its AVENTICS™ product brand, Emerson is one of the world’s leading manufacturers of pneumatic components and systems. The Emerson team from Laatzen stands for innovative pneumatic drive solutions in machine and factory automation. AVENTICS™ products include pneumatic cylinders, air supply management equipment and valve systems.

For Emerson and its customers, digital transformation is playing an increasingly important role. Modern industrial communication solutions and standardized IIoT protocols such as OPC UA hold enormous potential. They interconnect countless components, aggregate previously unused data and enable the optimization of key processes. Emerson has identified three areas of potential:

- Optimized Overall Equipment Effectiveness (OEE)

- More efficient and sustainable industrial processes

- Improved interoperability, integration, and security