In search of a suitable solution that meets all requirements, Oerlikon then came across Hilscher’s managed industrial IoT range of products and services. Oerlikon Metco and the Hattersheim-based specialist for industrial communication have been working together for some time in the field of industrial communication. Until then, the equipment manufacturer hadn‘t been involved in IIoT solutions. “One day, Mr. Banuleasa asked about our netFIELD OS, and we promptly made it available to him for detailed testing,” says Jan Luginbühl, Field Application Engineer at Hilscher Swiss GmbH.

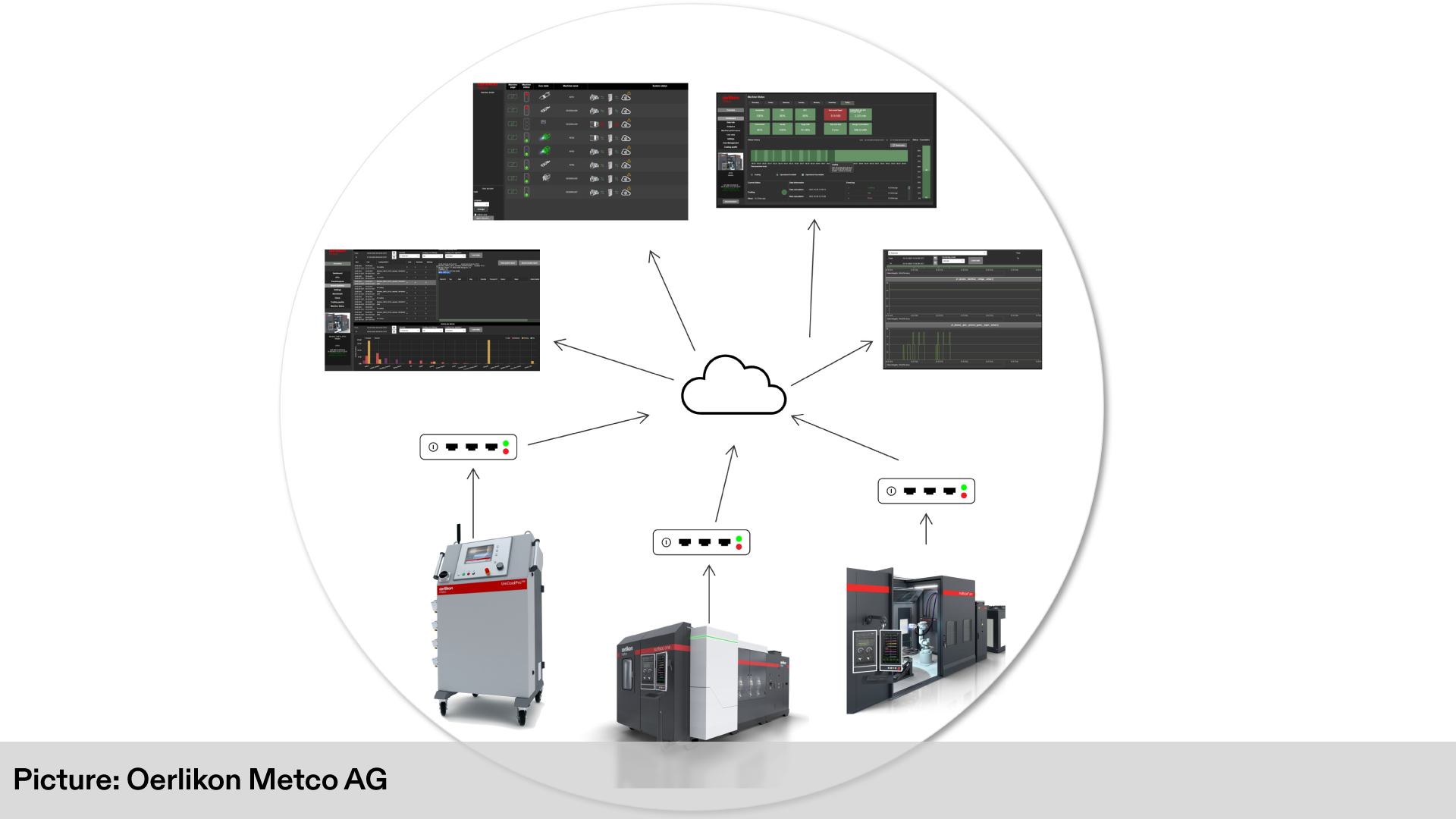

“Tests quickly showed that the Hilscher operating system met all our requirements,” Sabin Banuleasa sums up. “When we then also tested the cloud platform netFIELD.io using a trial account, we realized that the overall package from Hilscher was exactly what we had been looking for. It’s easy to use and is essentially plug and play with minimal effort involved in its implementation. Now that we have a reliable remote management solution, we can focus our engineering resources on our core business to develop application-specific solutions and digital services.” Oerlikon Metco eventually chose a combination of edge gateway, runtime and cloud portal. The edge gateways netFIELD Compact X8M are integrated into the machines, ensuring the availability of relevant machine data in real-time. This is made possible in large part thanks to the netFIELD OS, which works with Docker containers. Regular maintenance and updates performed by Hilscher ensure maximum security of business-critical data. The entire device management is done remotely via the netFIELD Cloud portal and its intuitive user interface.

Metco IIoT Cloud Service

- Exact overview on all thermal spray processing costs (material, power, process media, consumables, labor, etc.) with a recorded history

- Optimizes job schedules for thermal spray systems

- Helps identifying production cost and time variances for troubleshooting

- Reduces downtime by optimizing system maintenance schedules

- Manages multiple sites and roles for a globally installed base

- Advanced data processing through Oerlikon Expertise