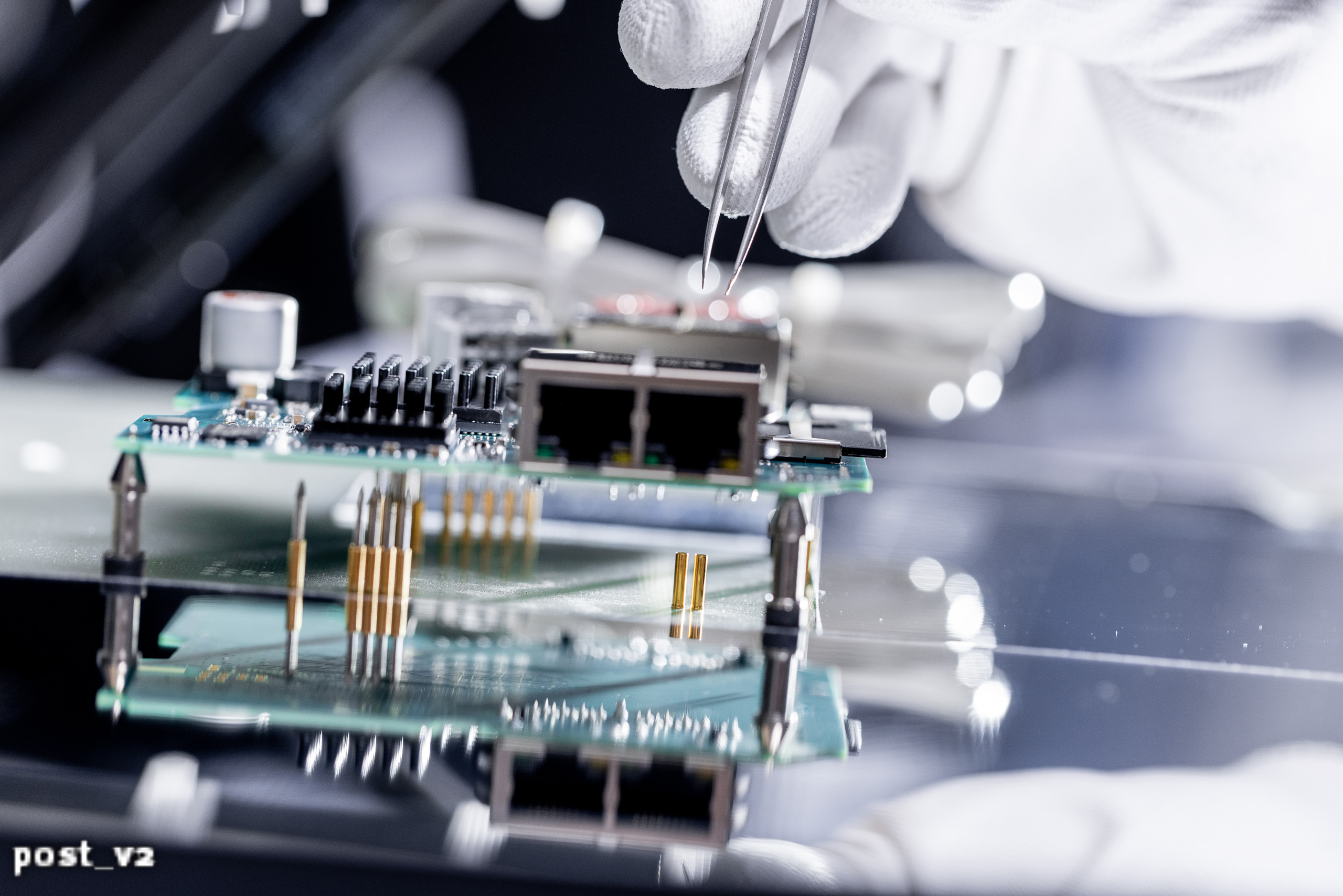

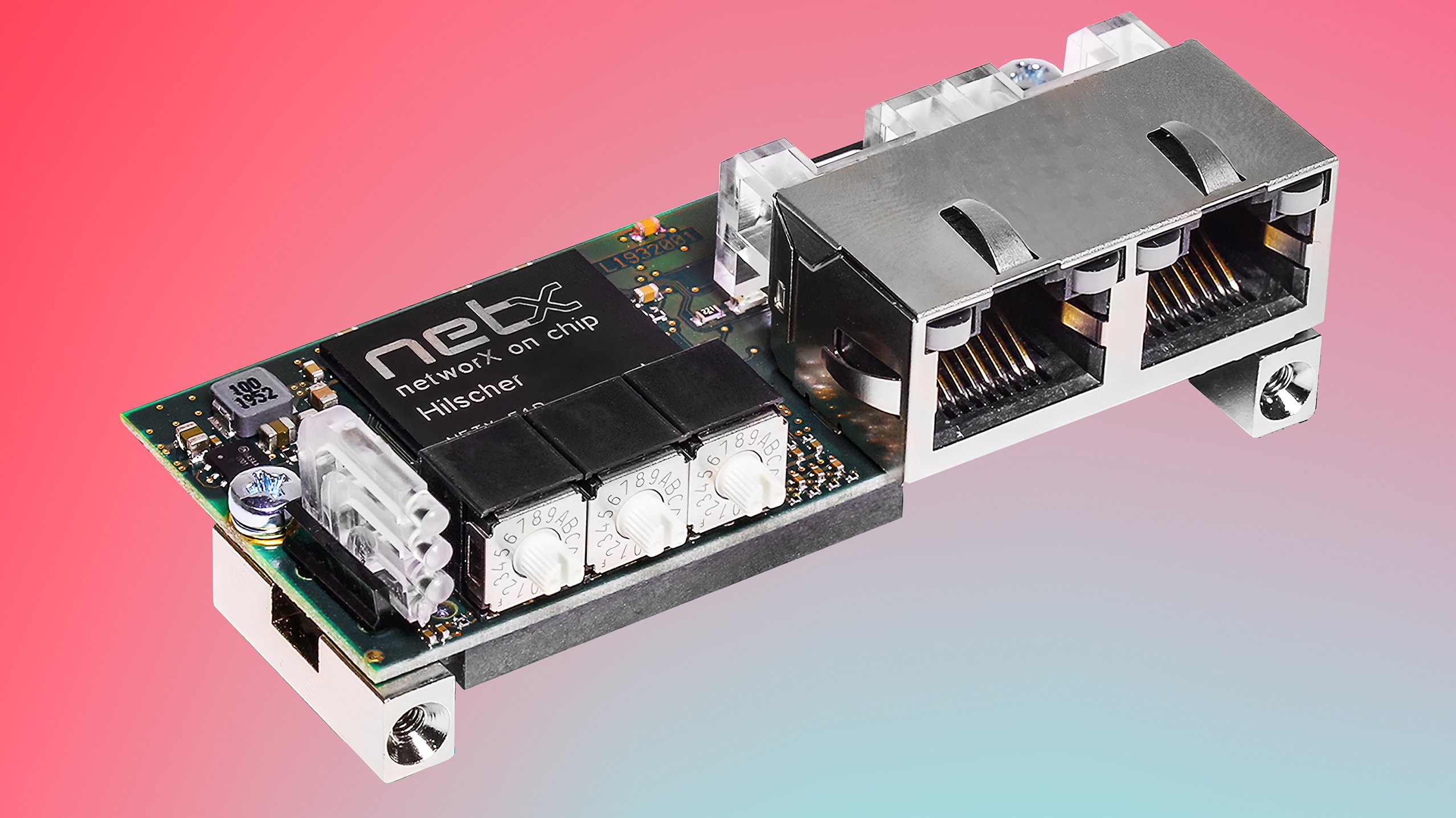

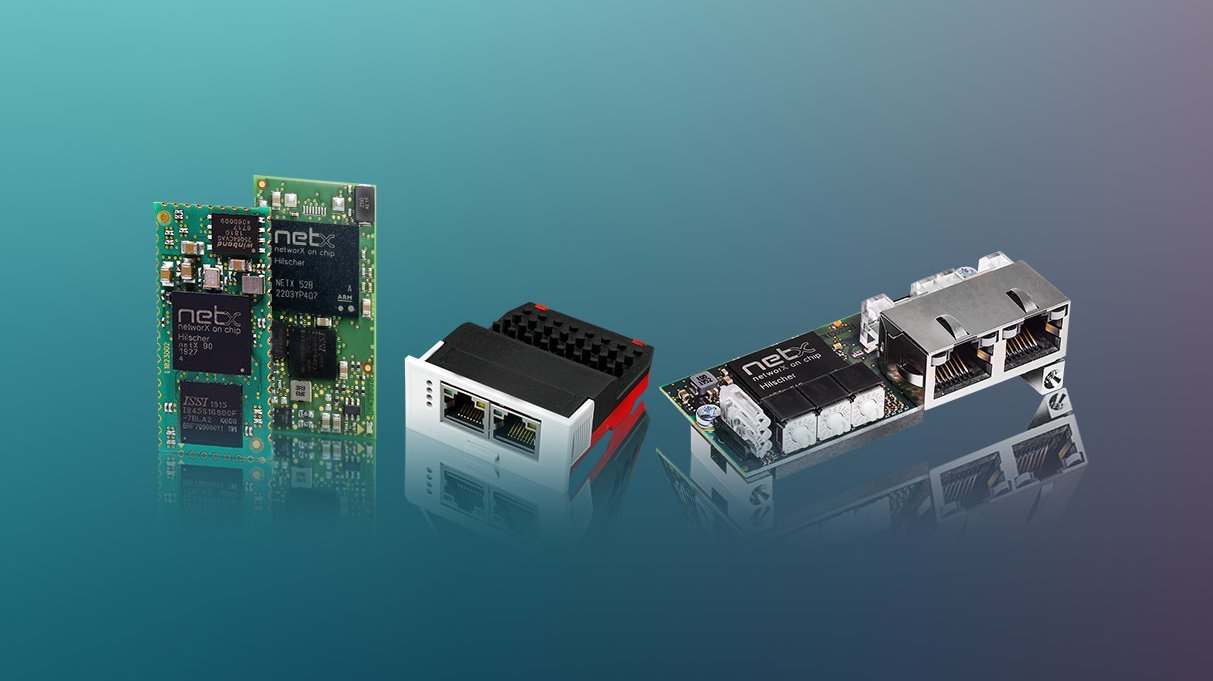

The comX communication module was developed to equip automation devices with a network interface. Here, all communication tasks are executed autarchically on the module - independent of the target platform processor.

comX supports all leading Real-Time Ethernet protocols as master or slave and covers all network-specific requirements in exactly one module. To support a line topology, the module is equipped throughout with two Ethernet ports. The protocol is changed quickly and reliably by loading a corresponding firmware and a software license for master.

In addition to Real-Time Ethernet communication, there is an integrated web server as well as an additional, transparent Ethernet channel to implement own IT solutions in the host processor of the automation device.

The comX communication module also offers you additional benefits, which are shown below: